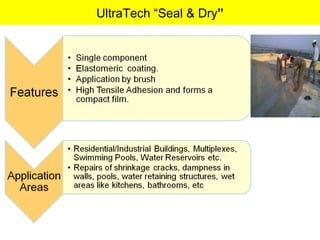

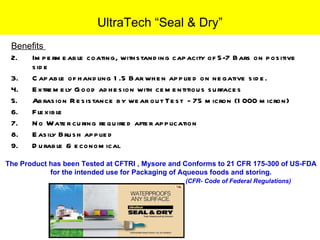

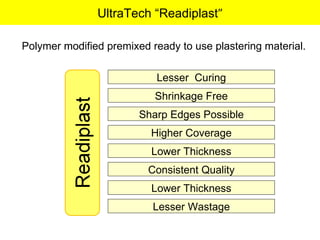

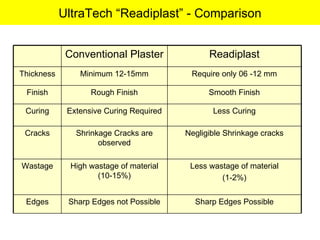

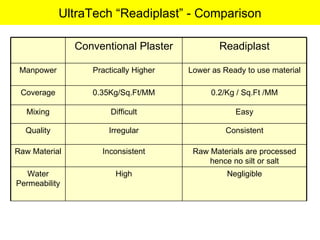

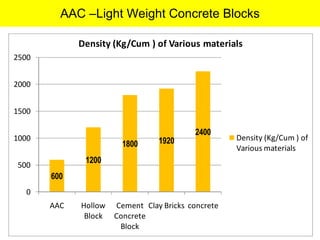

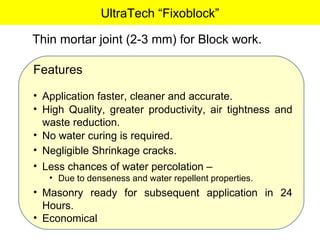

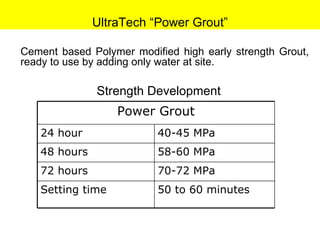

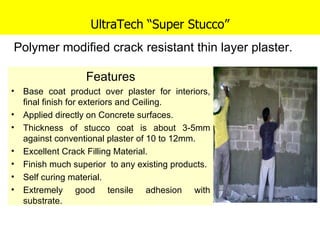

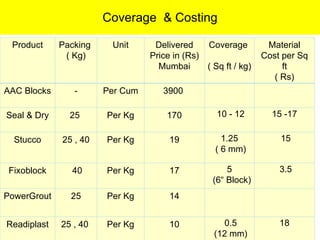

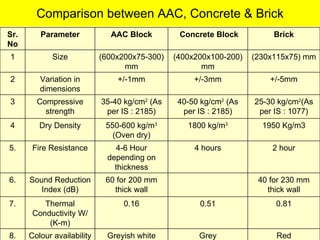

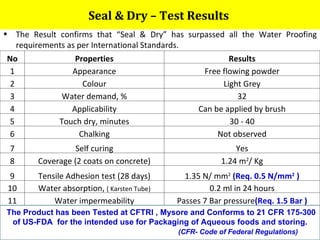

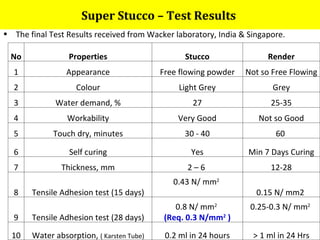

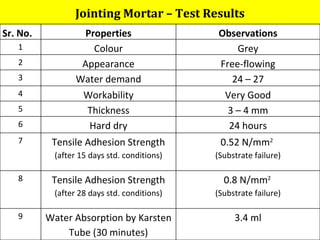

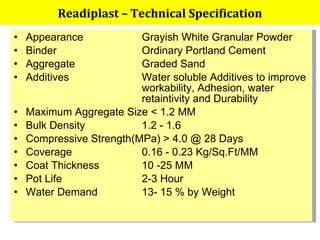

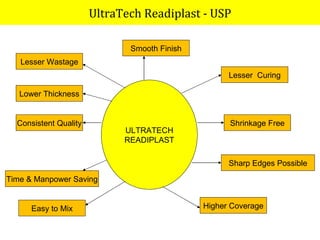

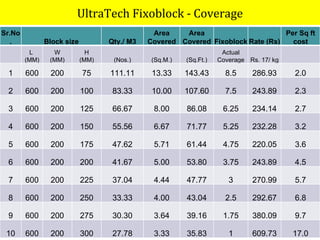

The document introduces several new building construction products from UltraTech Cement including waterproofing, plastering, jointing, and grouting materials. Key features and test results showing the performance advantages of these products over traditional alternatives are provided. These include greater strength, reduced curing times, higher coverage rates, and less wastage. Product specifications, pricing, and coverage details are also included.