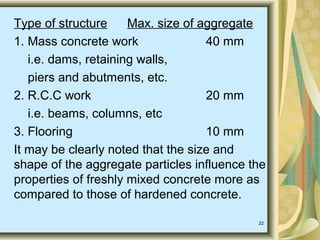

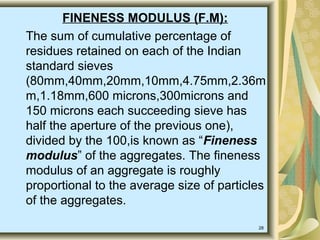

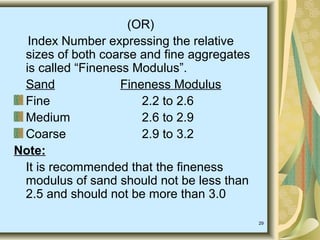

This document summarizes the classification and properties of aggregates used in construction. It defines aggregates as inert materials mixed with cement or lime for mortar or concrete. Aggregates are classified as fine or coarse based on particle size. Common fine aggregates include sand from various sources, while coarse aggregates include crushed stone and gravel. Key properties discussed include size, shape, composition and performance in tests such as crushing value, impact value and abrasion value. Sieve analysis is also described to determine particle size distribution. An ideal aggregate is characterized as hard, strong, dense and free of impurities to provide durable concrete.