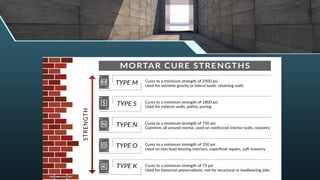

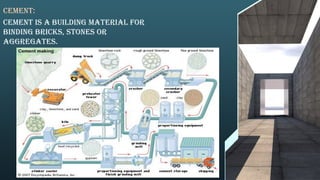

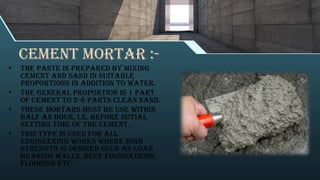

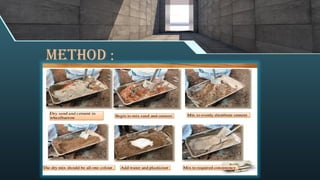

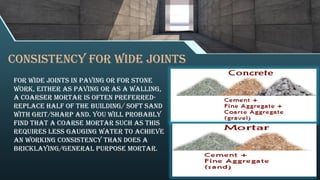

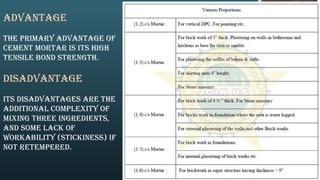

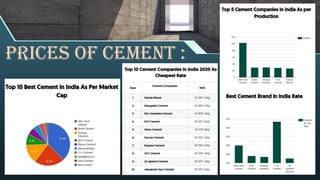

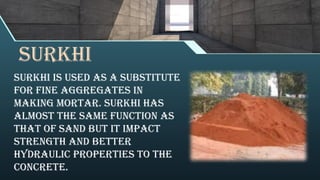

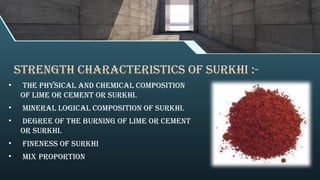

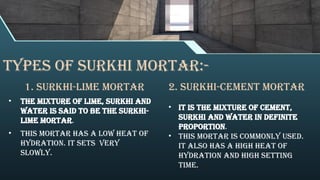

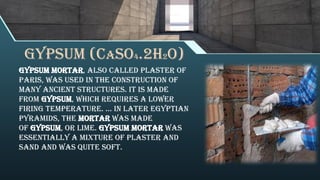

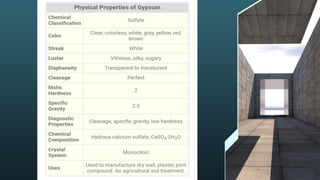

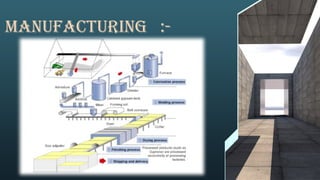

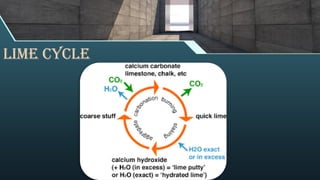

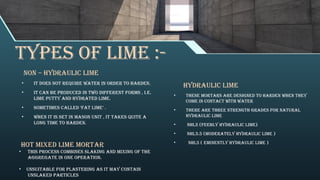

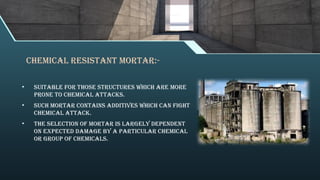

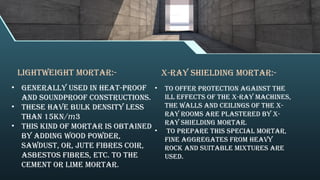

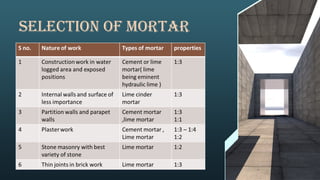

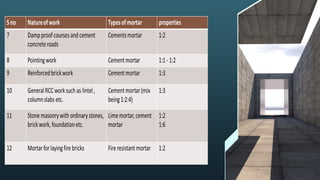

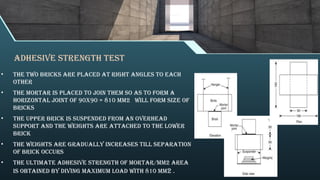

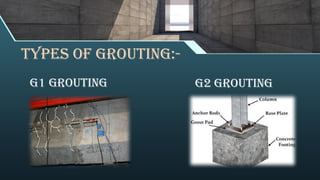

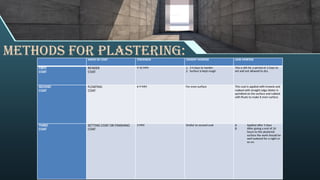

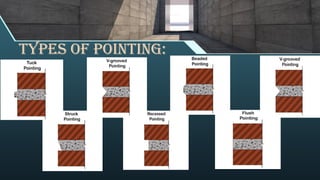

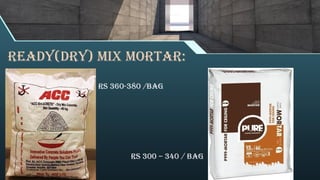

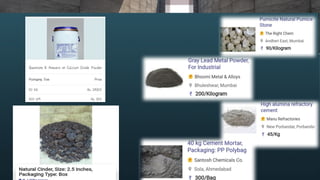

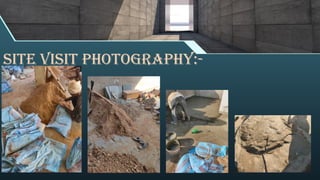

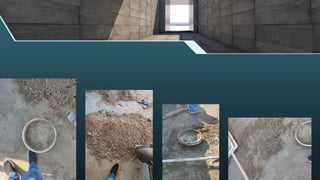

The document provides a comprehensive overview of mortar, detailing its definition, constituents, properties, types, and applications. It covers various types of mortar based on binding materials, bulk density, and nature of application, alongside the process for their preparation and testing methodologies. Additionally, it discusses specialized mortars and techniques like grouting and guniting, essential for construction practices.