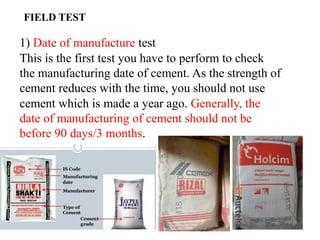

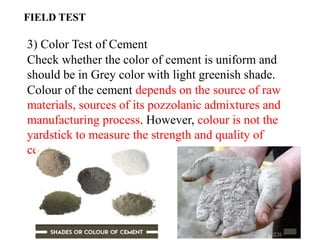

The document focuses on various testing methods for cement, including both field and laboratory tests to assess quality and suitability for construction. Key tests discussed include the date of manufacture, lumps test, color test, fineness test, setting time test, and compressive strength test, each critical for ensuring the integrity of cement. Proper storage and handling techniques, along with standard specifications, are emphasized to maintain cement's effectiveness over time.

![OBJECTIVE:

To determine the fineness of cement by means of the 75micron/

micromillimeter (No 200) sieve.

INSTRUMENTS & ACCESORIES:

1. Standard balance with 100grams weighing capacity

2. No 200 sieve with pan and cover

3. Brush

4. 100g ordinary Portland cement

FINENESS OF CEMENT BY DRY SIEVING

[ASTM C-184-94e1 (withdrawn 2002)]

LABORATORY TESTS: FINENESS TEST](https://image.slidesharecdn.com/cementtests-210324055535/85/Cement-tests-21-320.jpg)

![Procedure:

1. Break down any air-set lumps in the cement sample with fingers.

2. Weigh accurately 100grams of the cement and place it in a standard

No 200 sieve.

3. Continuously sieve the sample for 15 minutes.

4. Weigh the residue left after 15 minutes of sieving.

5. Repeat the procedure for trials 2 and 3.

Computation:

The percentage weight of residue over the total sample is reported.

FINENESS OF CEMENT BY DRY SIEVING

[ASTM C-184-94e1 (withdrawn 2002)]

LABORATORY TESTS: FINENESS TEST](https://image.slidesharecdn.com/cementtests-210324055535/85/Cement-tests-22-320.jpg)

![Observation sheet:

FINENESS OF CEMENT BY DRY SIEVING

[ASTM C-184-94e1 (withdrawn 2002)]

LABORATORY TESTS: FINENESS TEST](https://image.slidesharecdn.com/cementtests-210324055535/85/Cement-tests-23-320.jpg)