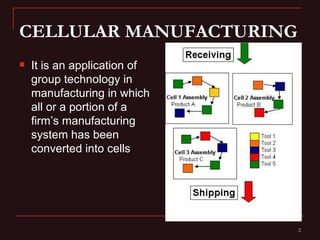

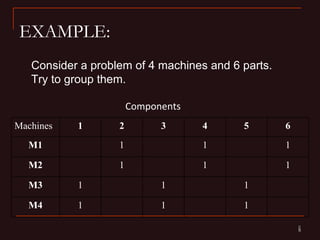

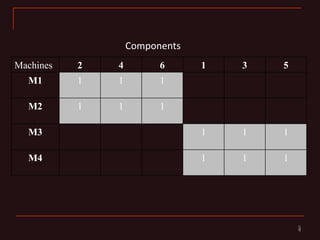

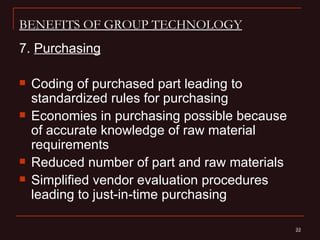

This document discusses cellular manufacturing and group technology. It defines cellular manufacturing as converting a manufacturing system into cells based on grouping machines and components. It describes the four stages of production flow analysis used to form machine-component groups: machine classification, checking part and production information, factory flow analysis, and machine-component group analysis. Benefits of cellular manufacturing include reduced flow times and inventories. Group technology emphasizes grouping similar parts and machines to standardize processes. Benefits include reductions in engineering costs, production time and defects through standardization.