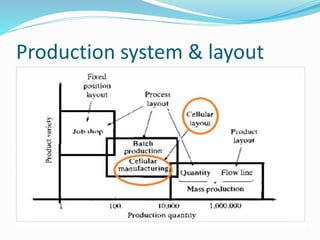

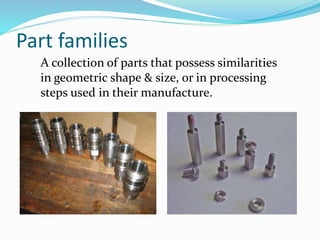

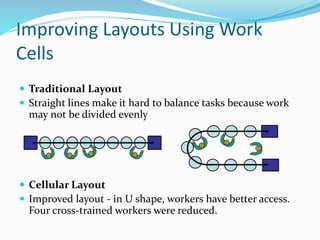

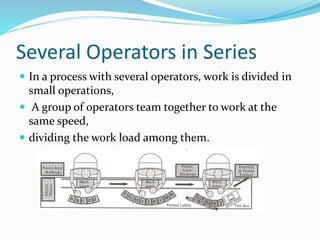

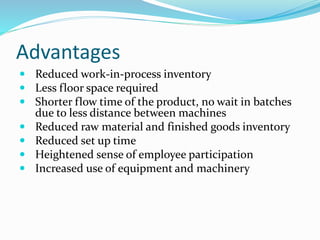

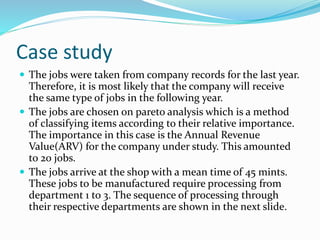

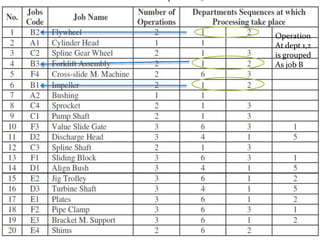

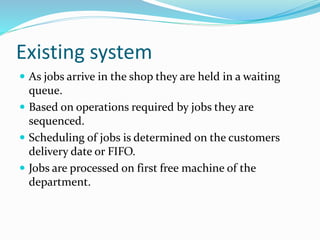

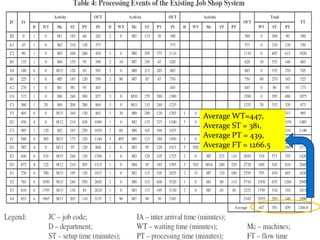

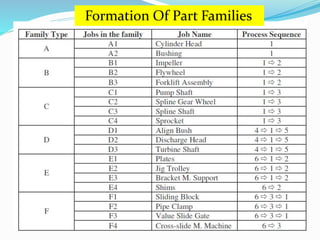

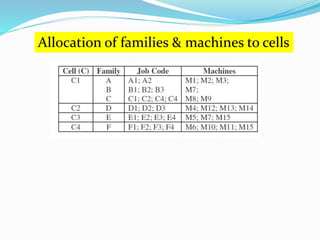

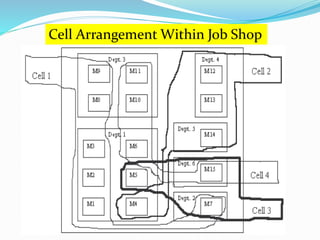

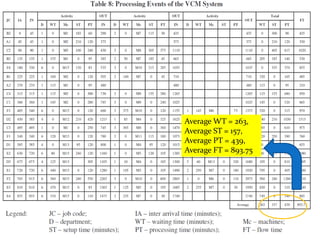

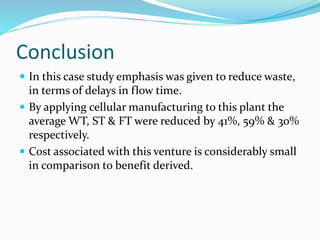

This document discusses production systems and cellular manufacturing. It defines production systems as transforming inputs into finished products using people, materials, and machines. Production systems are classified as job shop, batch, or mass production depending on product customization and volume. Cellular manufacturing organizes equipment into machine cells that specialize in specific part families. This improves production flow and flexibility while reducing space and inventory requirements. The document also covers group technology, how to identify part families, and provides a case study comparing traditional and cellular layouts that demonstrates reduced flow times using the latter approach.