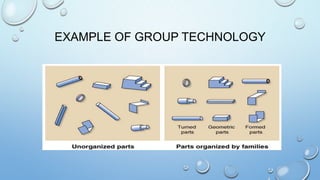

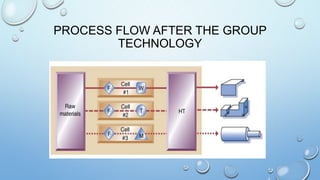

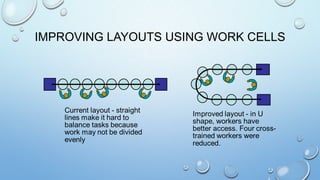

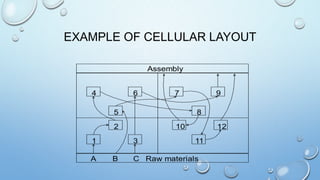

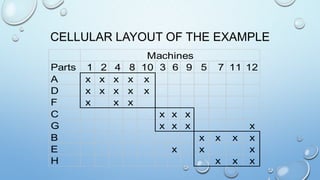

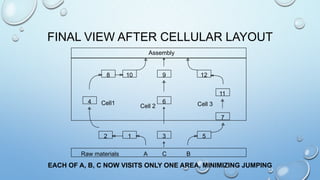

Cellular layout is a manufacturing approach that organizes equipment and workstations into cells dedicated to producing families of parts, optimizing production flow in small lots. It leverages group technology to facilitate just-in-time manufacturing, aiming to reduce waste and improve efficiency through better use of resources and employee empowerment. Although it offers several advantages like reduced handling time and enhanced scheduling, challenges include potential issues with cell formation and the need for cross-trained workers.