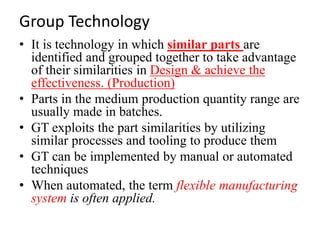

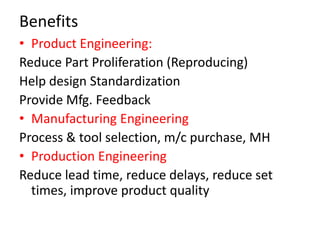

Group technology is a manufacturing strategy that involves grouping similar parts together and processing them in the same production cells using similar machines and tools. The key aspects are:

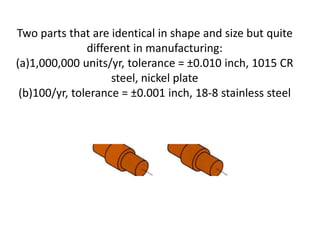

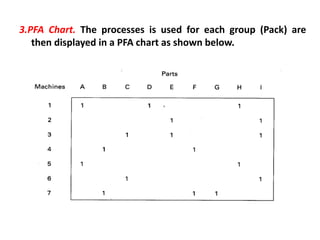

- Identifying part families based on similarities in geometry, manufacturing processes, etc.

- Organizing production facilities into manufacturing cells specialized for certain part families to reduce setup times and transportation.

- Implementing flexible manufacturing systems and just-in-time production to further improve efficiency.

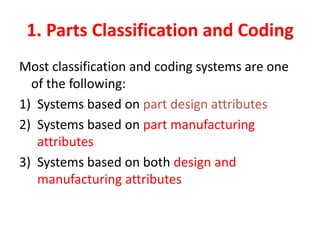

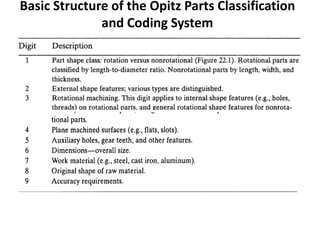

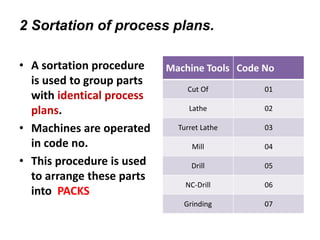

- Classification and coding systems help systematically identify part similarities and differences to effectively group parts into families.