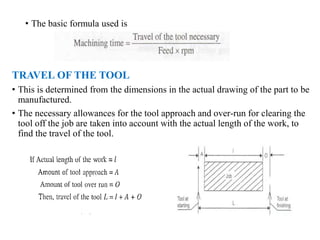

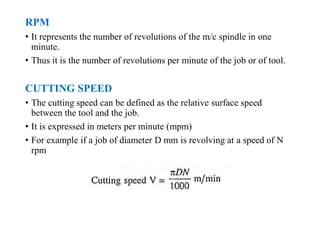

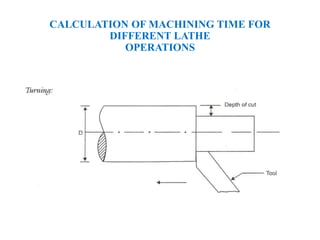

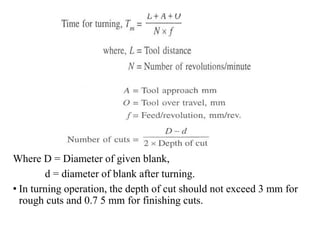

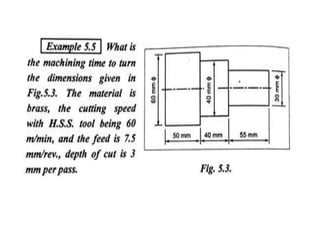

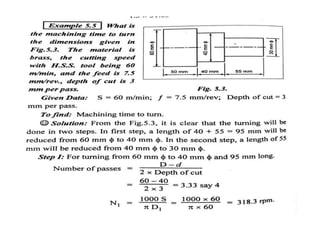

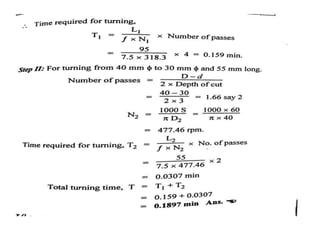

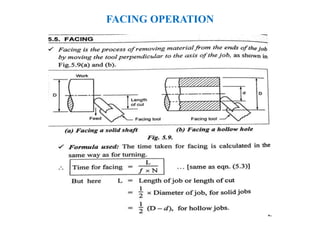

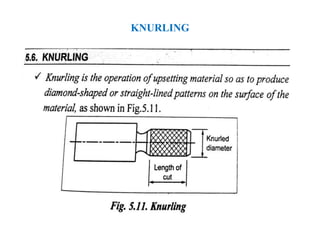

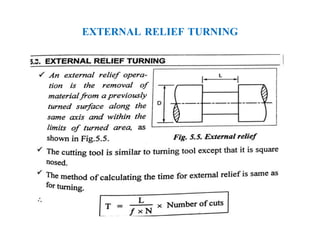

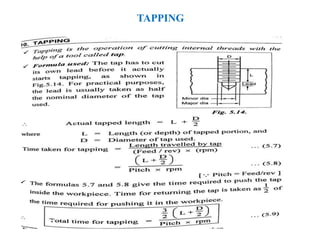

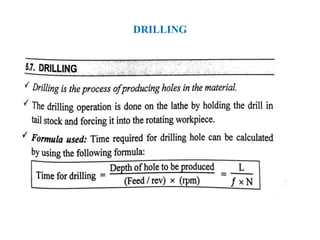

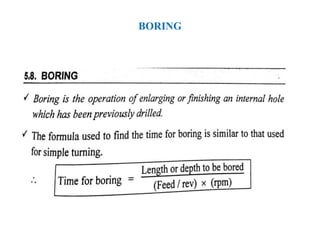

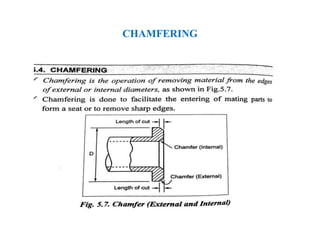

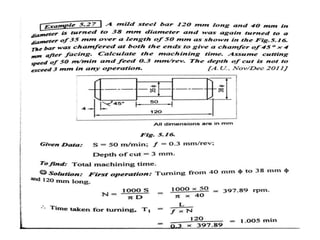

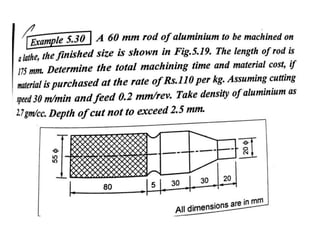

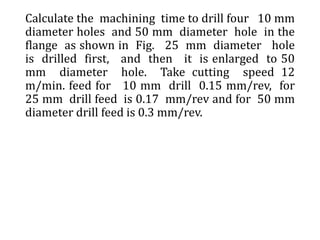

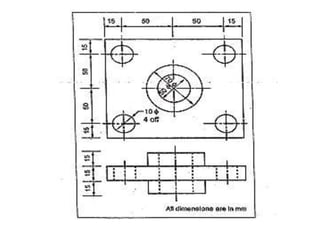

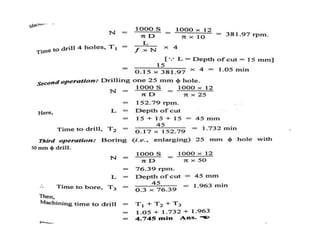

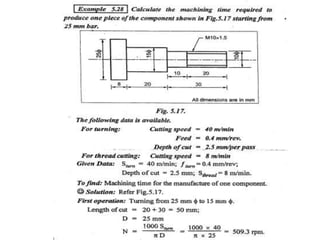

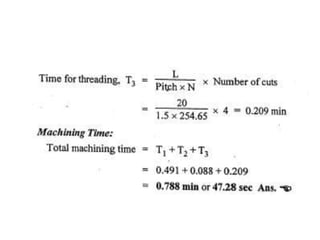

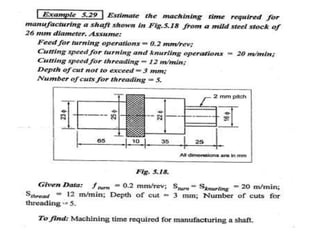

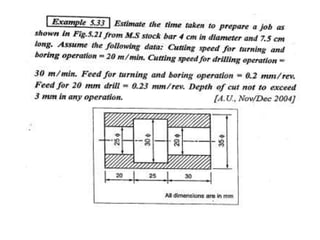

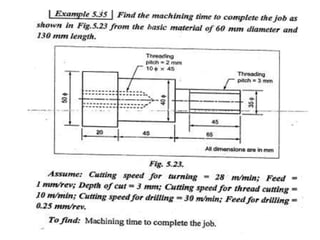

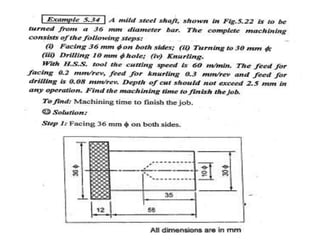

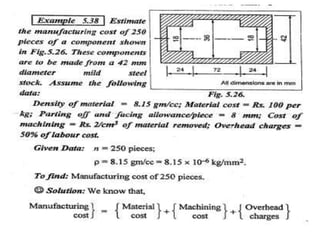

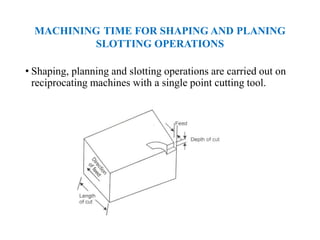

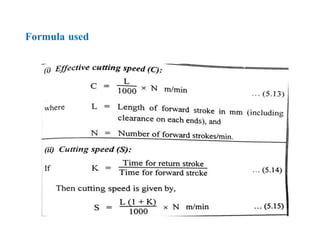

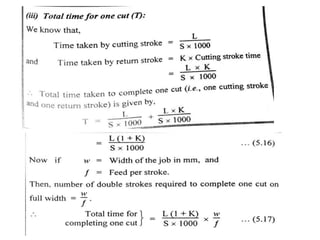

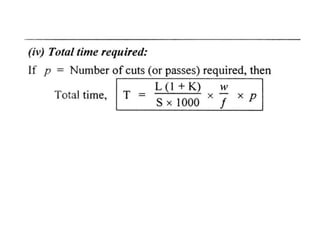

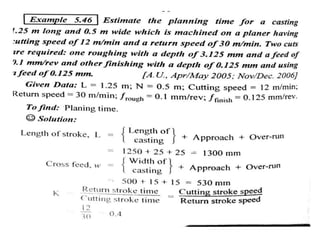

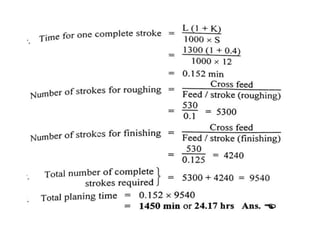

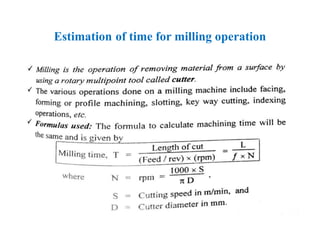

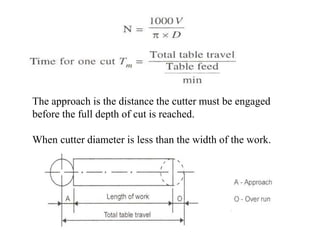

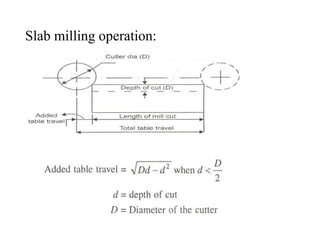

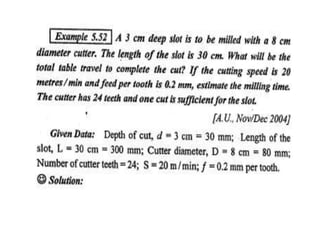

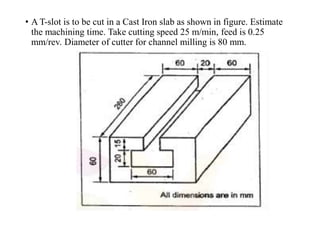

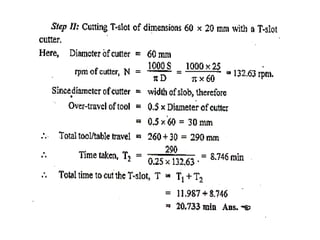

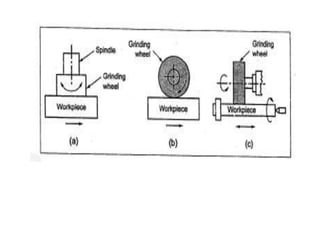

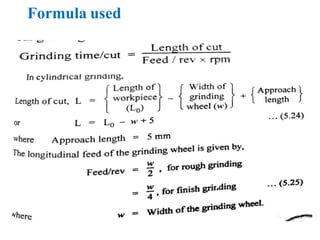

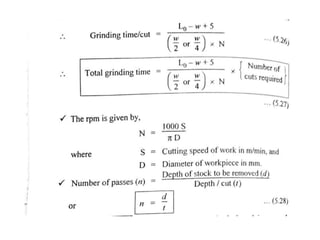

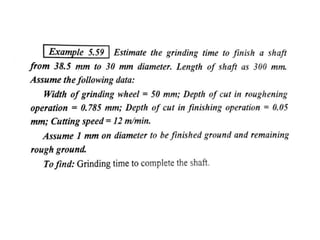

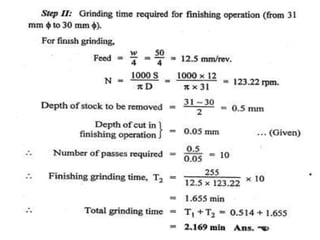

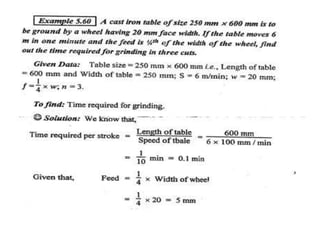

This document discusses methods for calculating machining times for various operations including lathe operations like turning, facing, knurling, reaming, tapping, and threading. It also covers drilling, boring, milling, shaping, planning, grinding, and provides formulas for calculating machining times based on factors like tool travel, feed rate, depth of cut, rpm, and cutting speed. Examples are provided to demonstrate how to estimate machining times for specific parts and operations using the appropriate formulas and time allowance factors. Calculating accurate machining times is important for cost estimation of parts involving multiple machining steps.