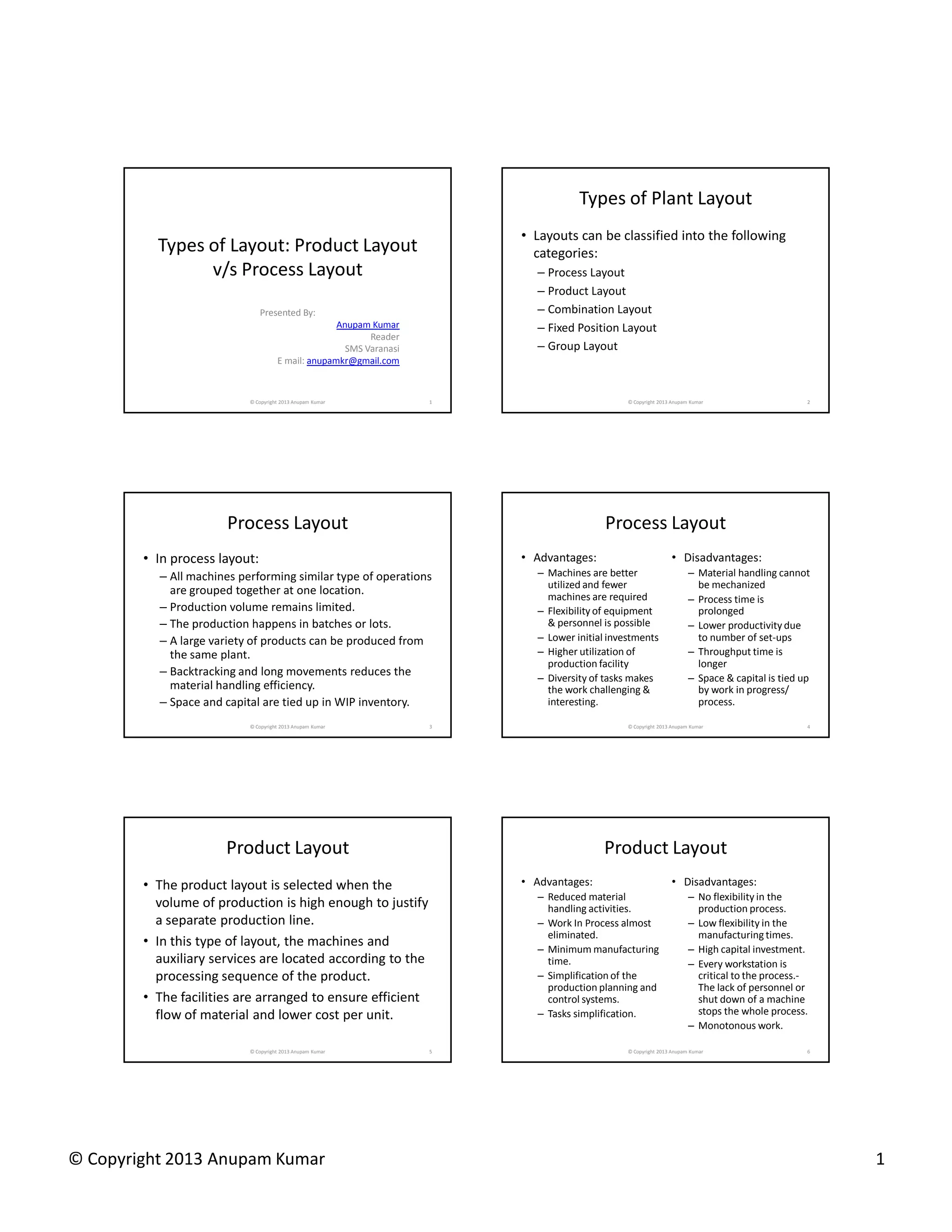

The document discusses different types of plant layouts, including process layout, product layout, combination layout, fixed position layout, and group layout. It provides details on the key characteristics and advantages and disadvantages of each layout type. It also includes an example of a company that is evaluating its layout and proposes which type of layout may be most suitable.