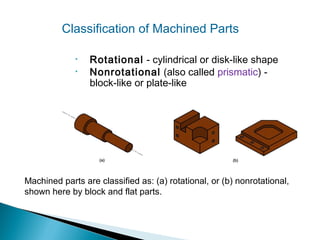

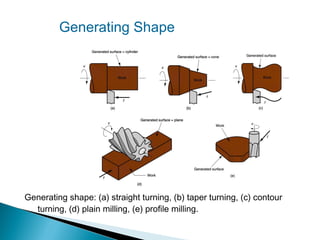

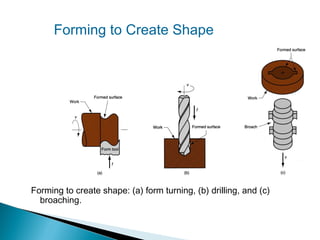

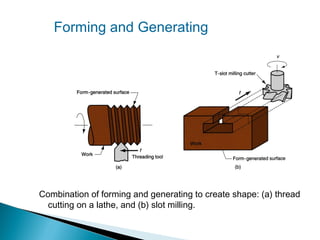

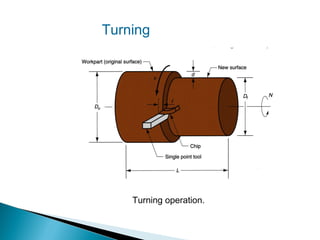

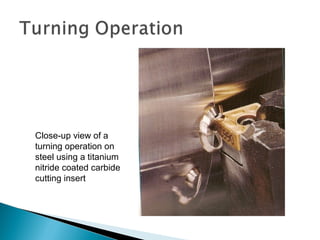

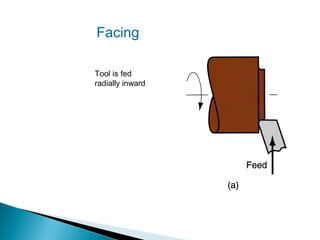

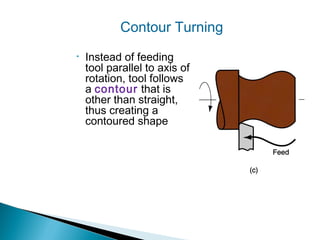

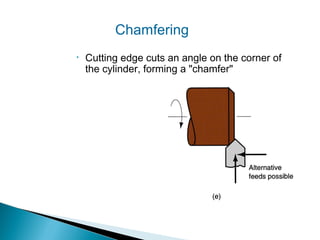

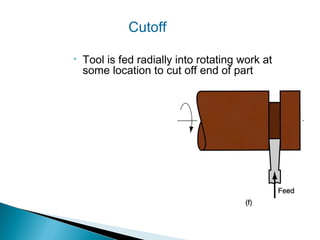

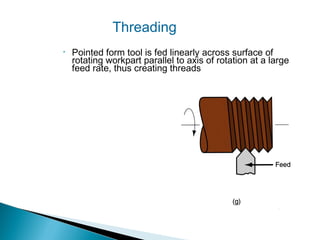

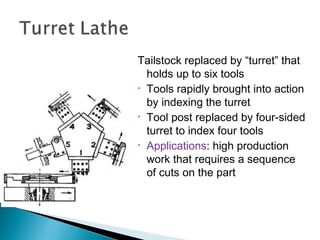

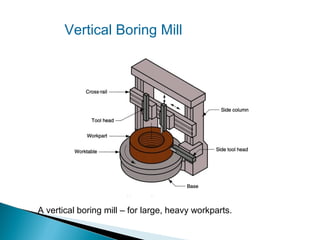

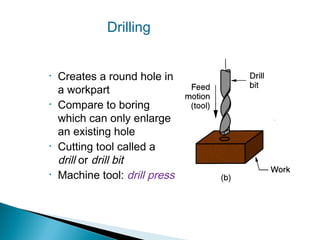

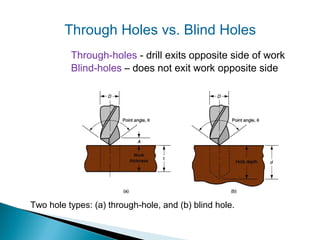

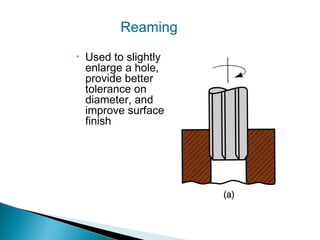

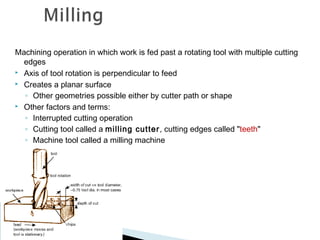

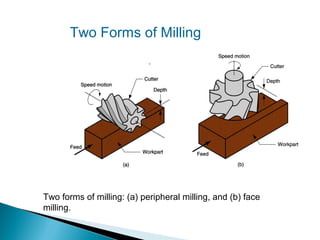

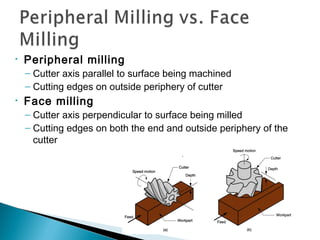

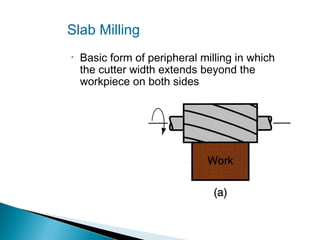

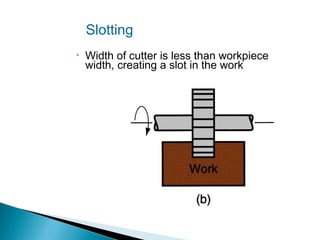

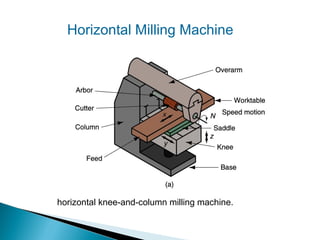

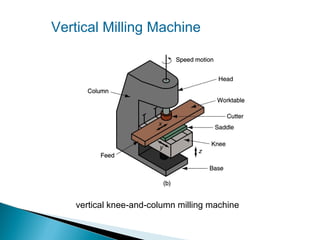

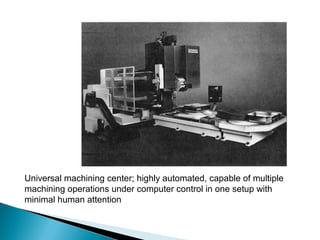

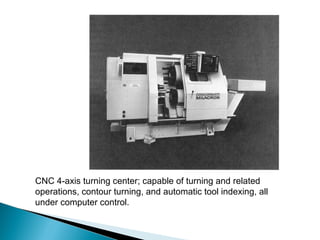

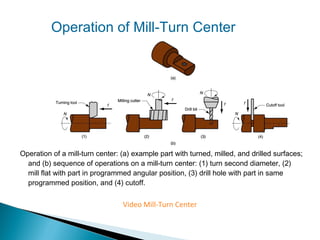

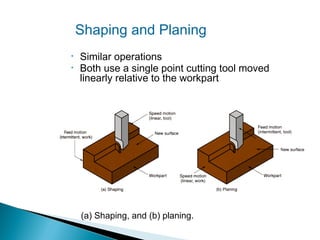

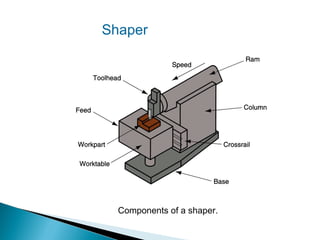

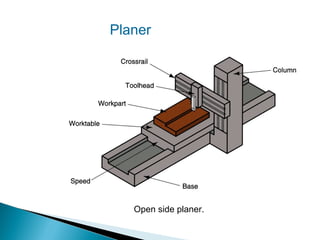

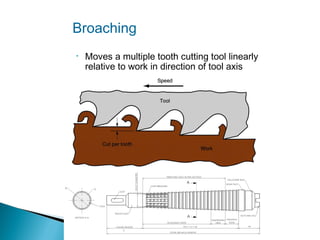

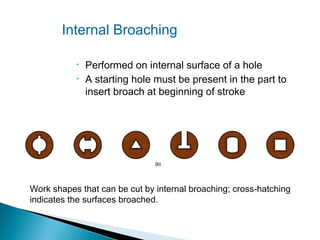

The document outlines various machining operations, including turning, drilling, milling, and broaching, highlighting their functions, classifications, and tools involved. It details the distinctions between different processes like boring versus turning and describes machines such as lathes and milling centers. Additionally, the document emphasizes the capabilities and applications of these machining processes in producing precise part geometries and features.