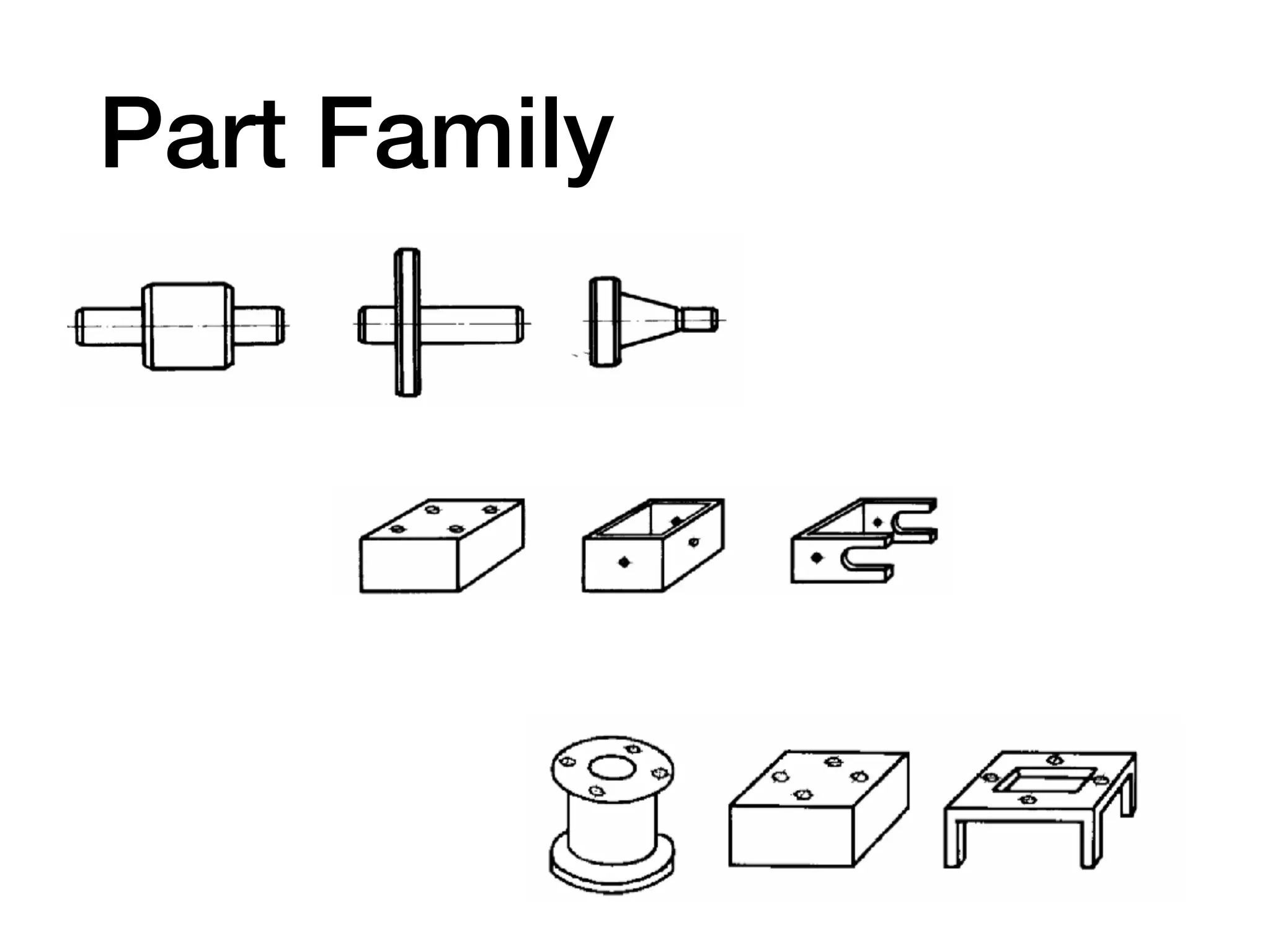

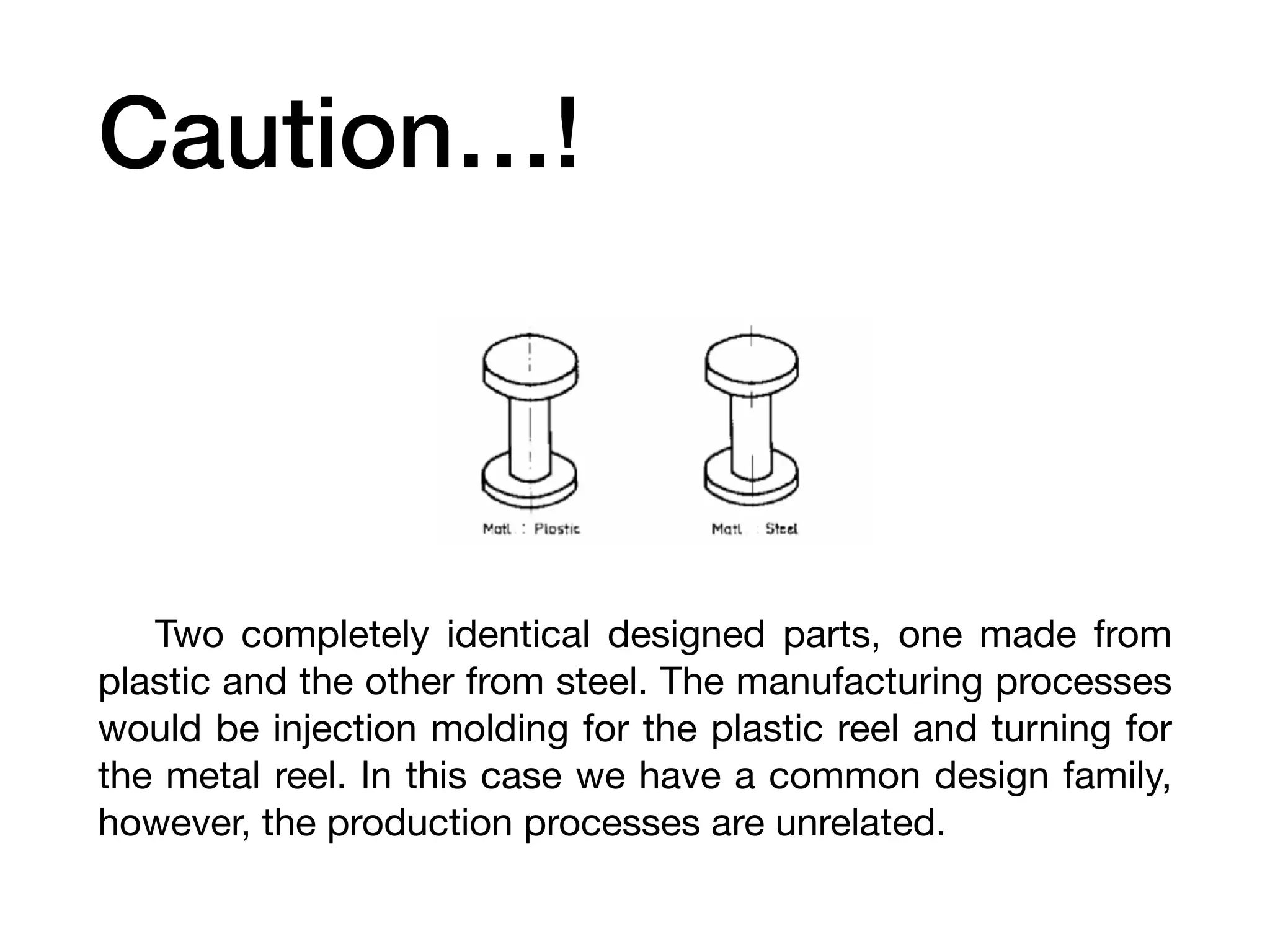

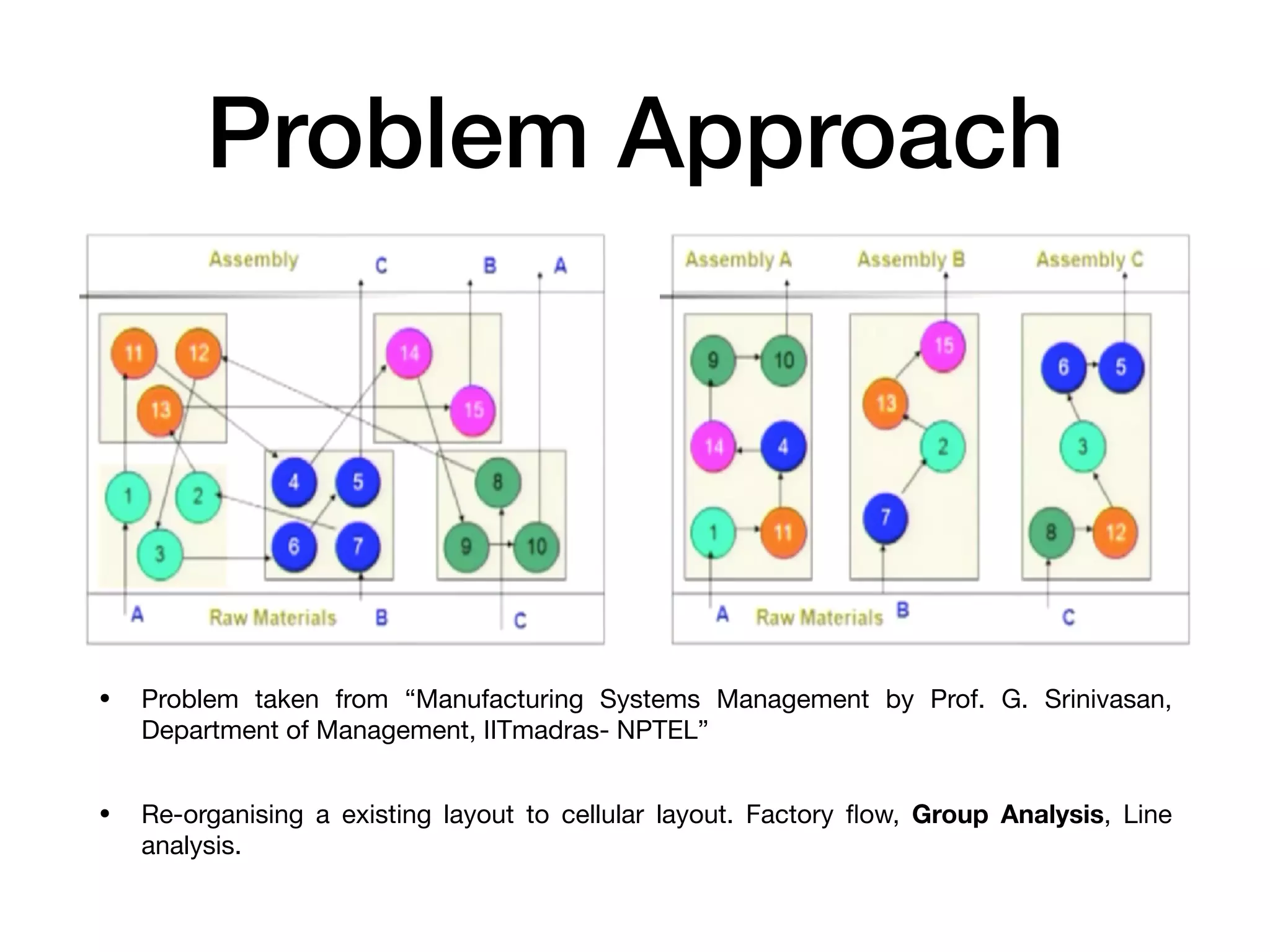

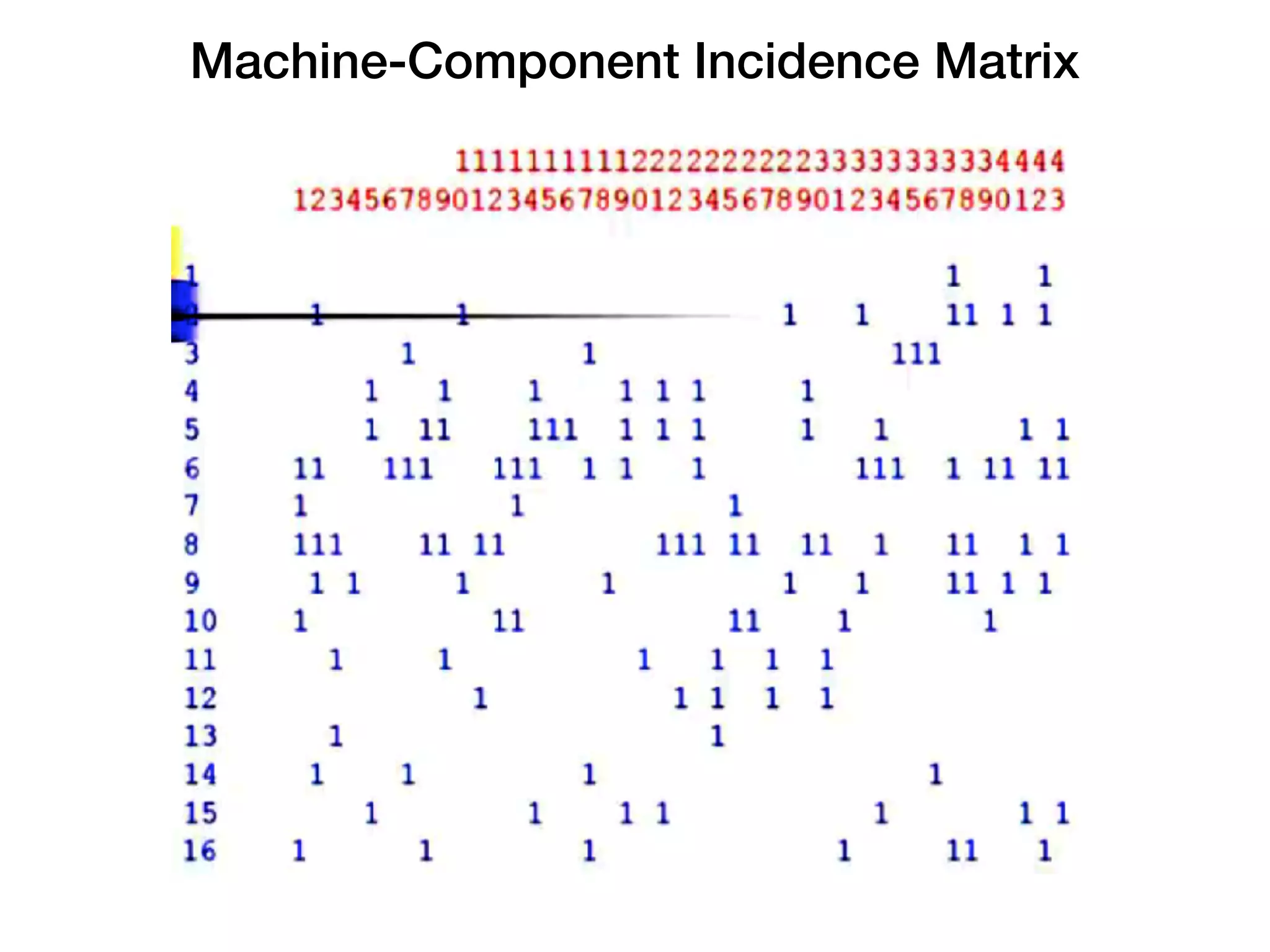

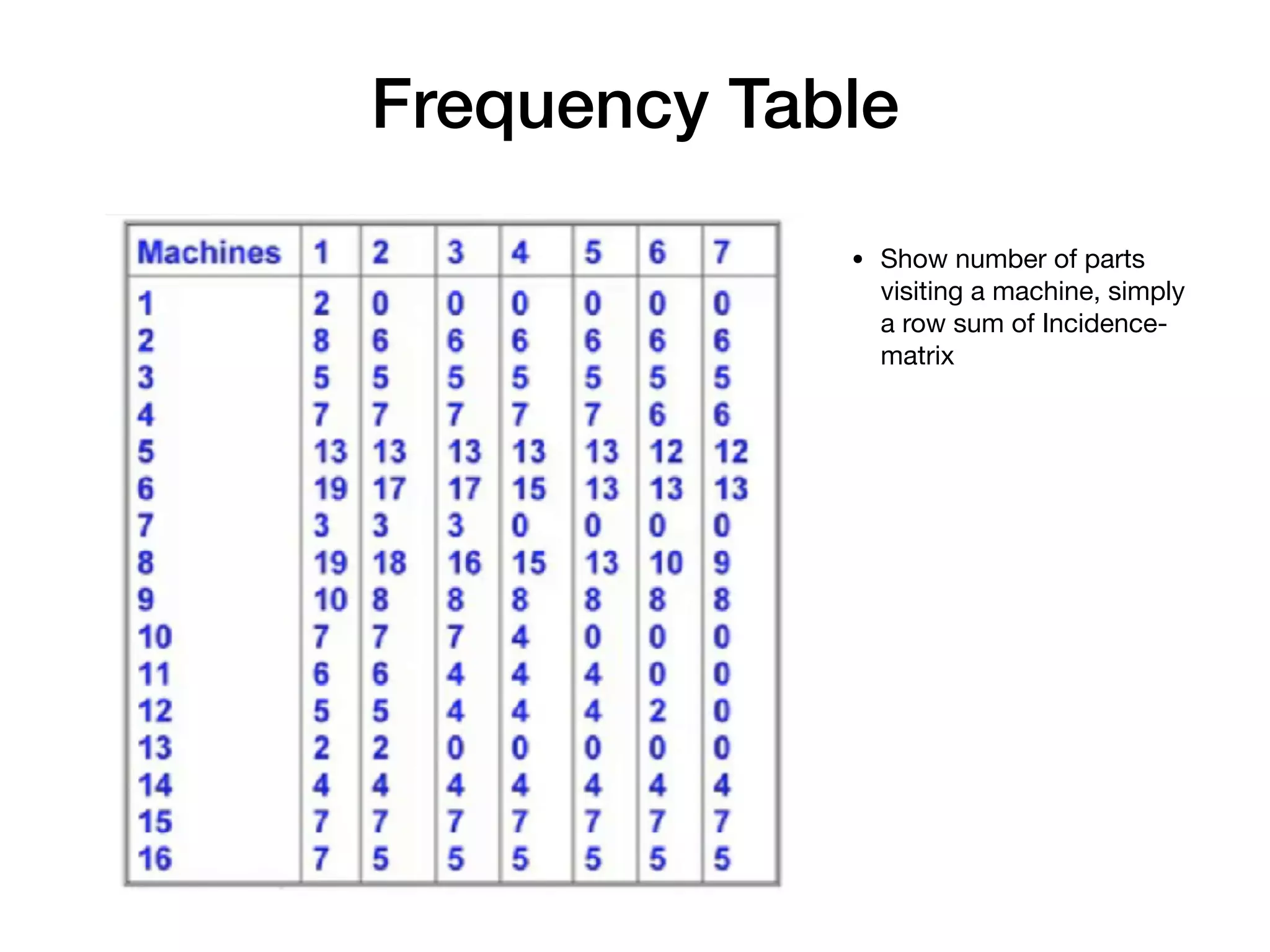

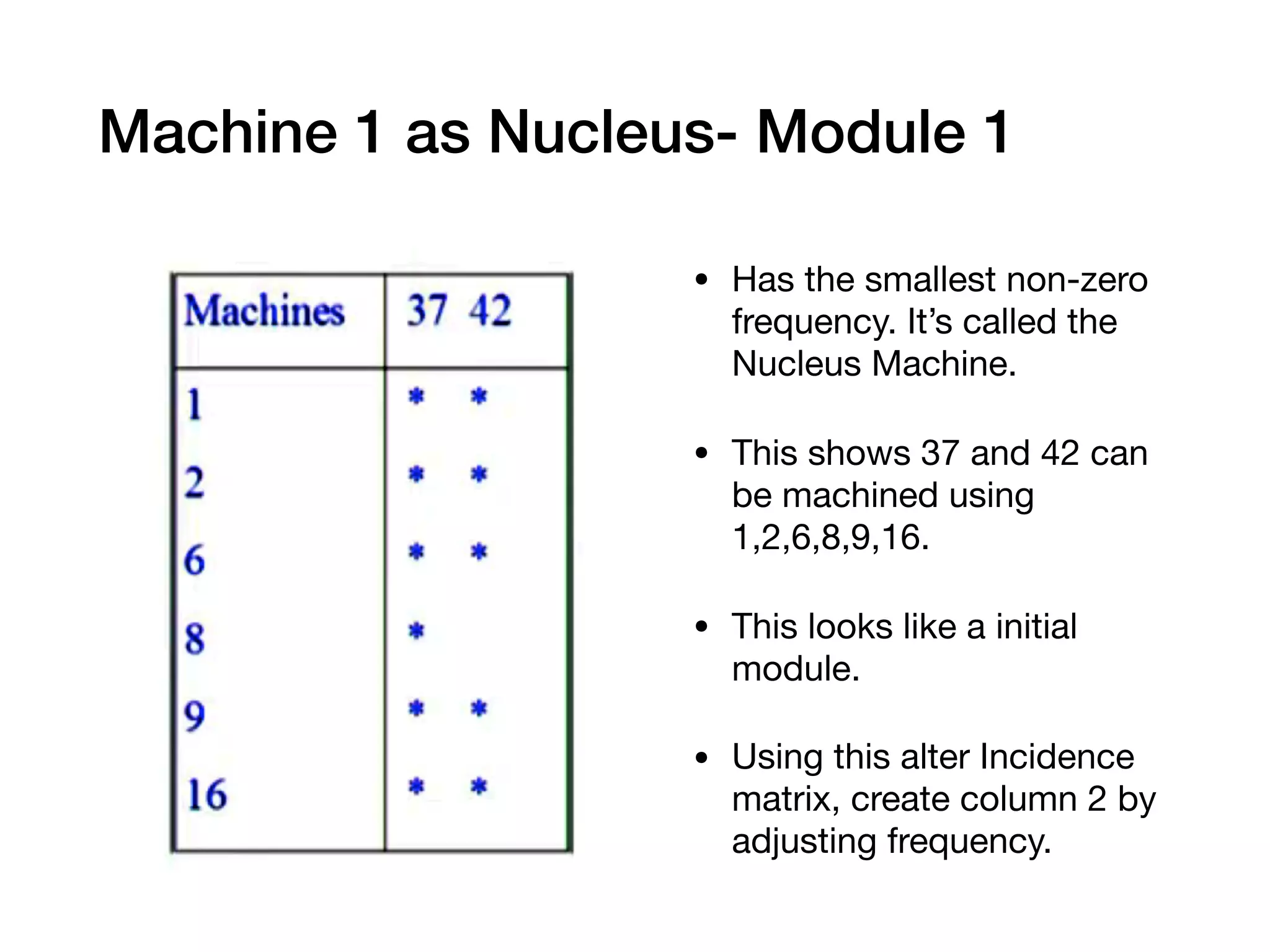

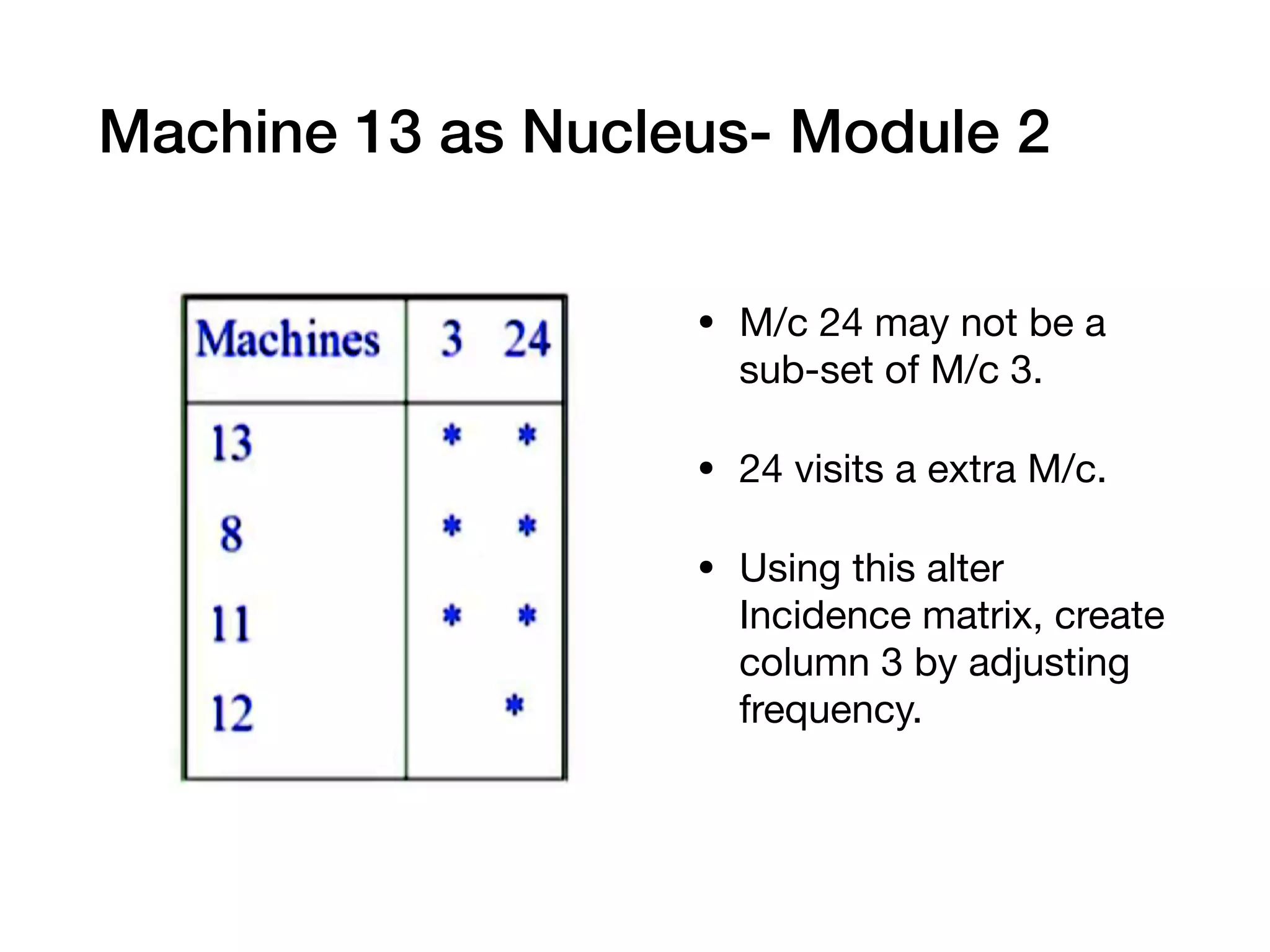

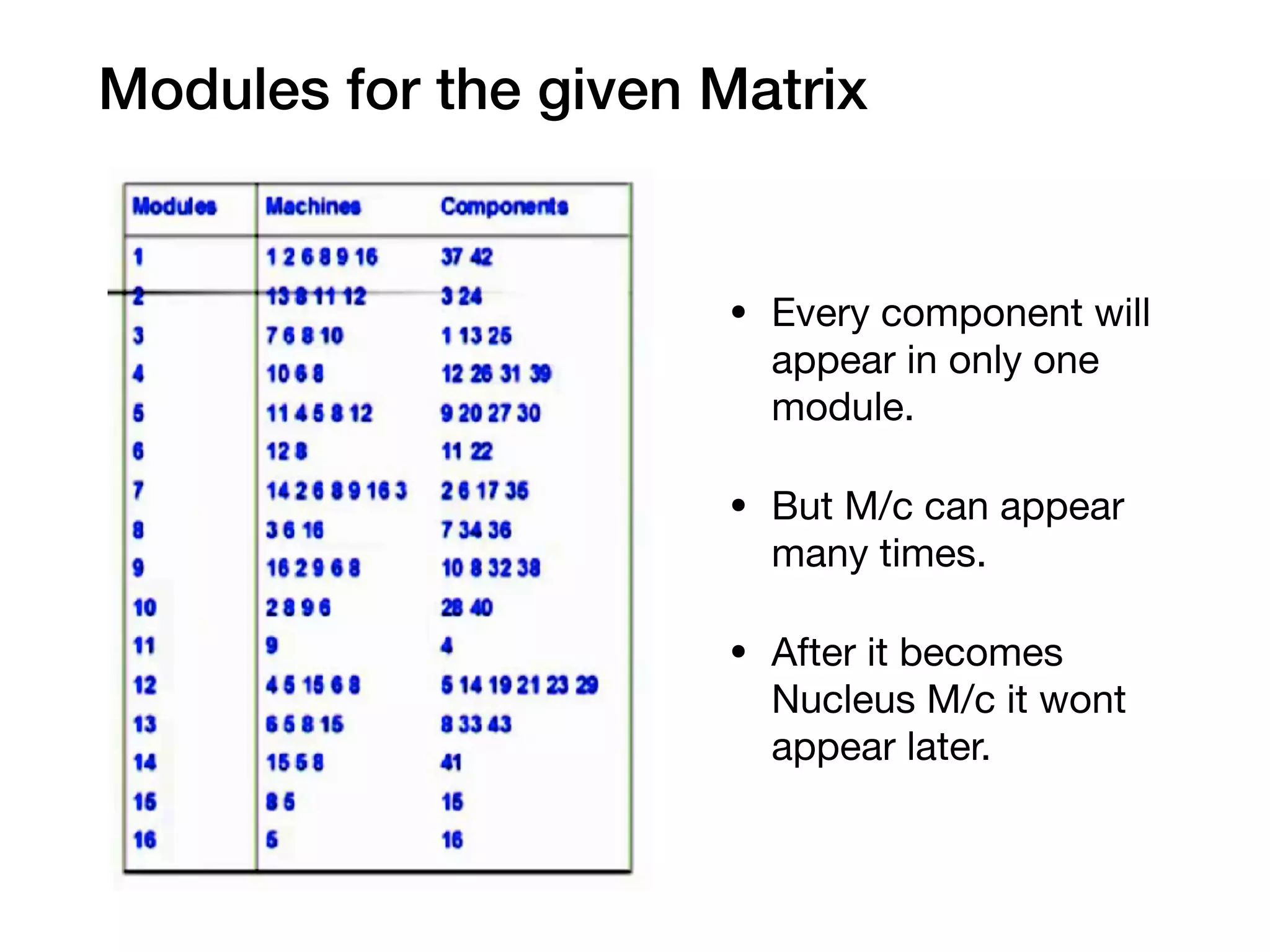

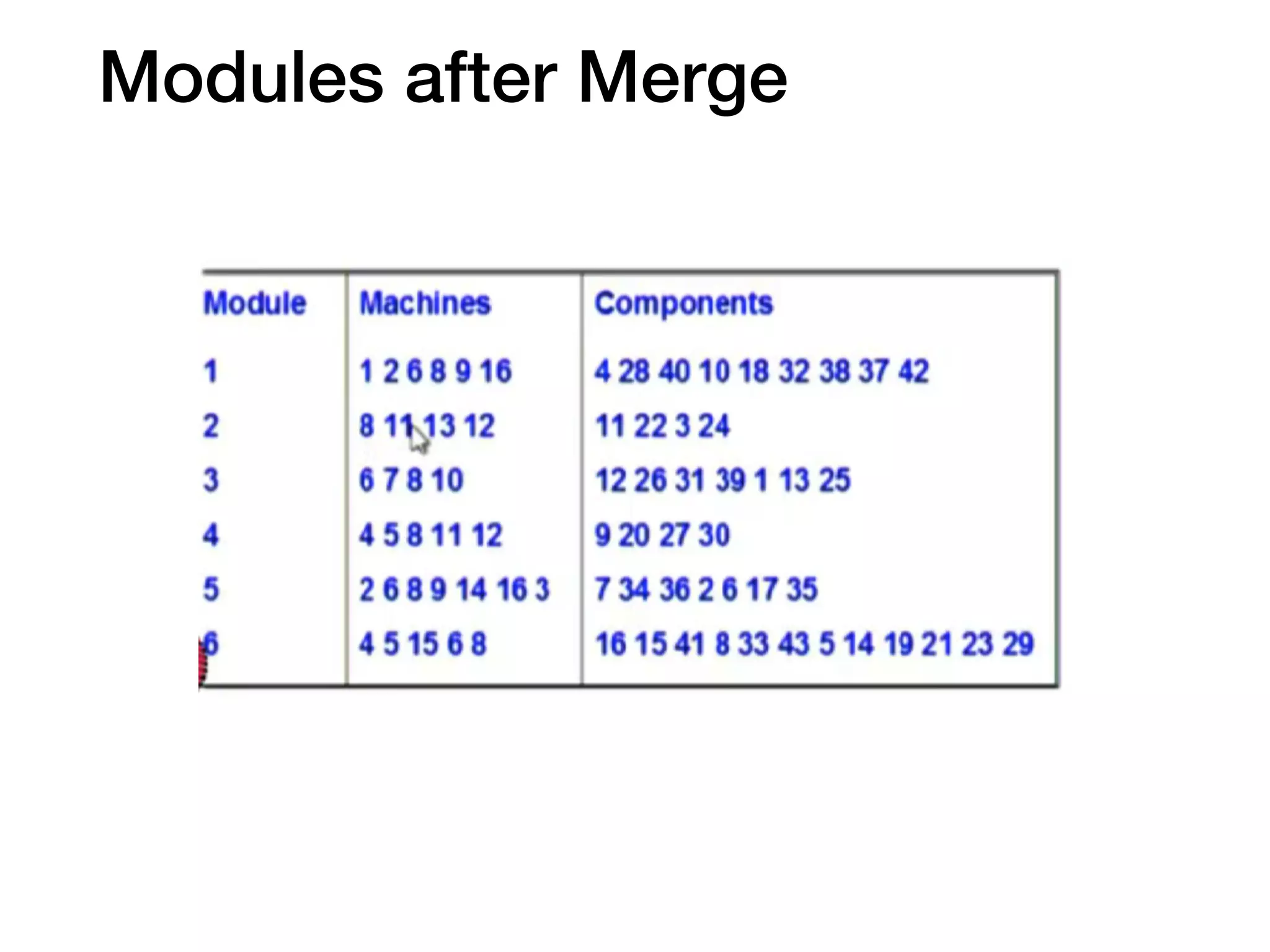

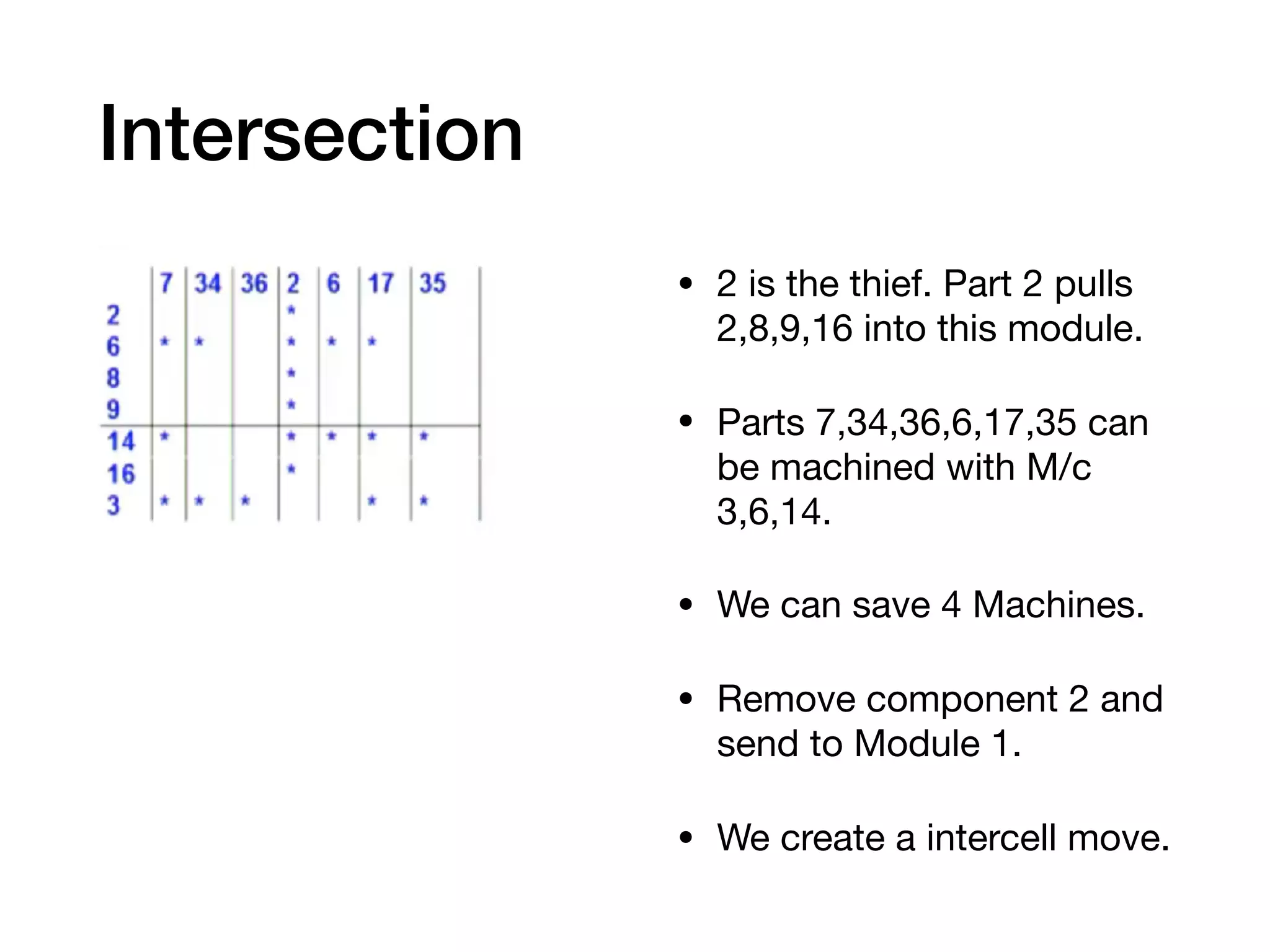

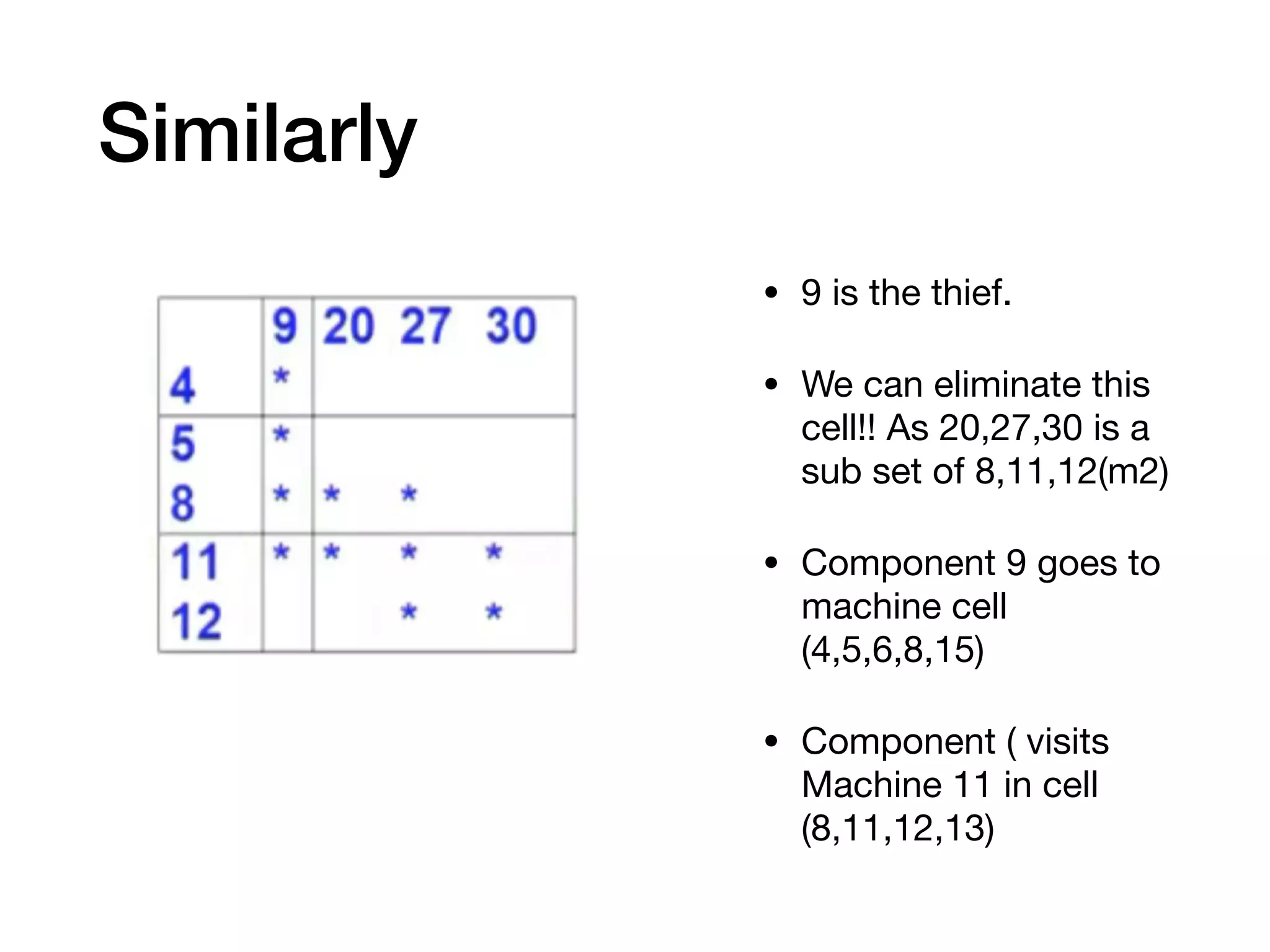

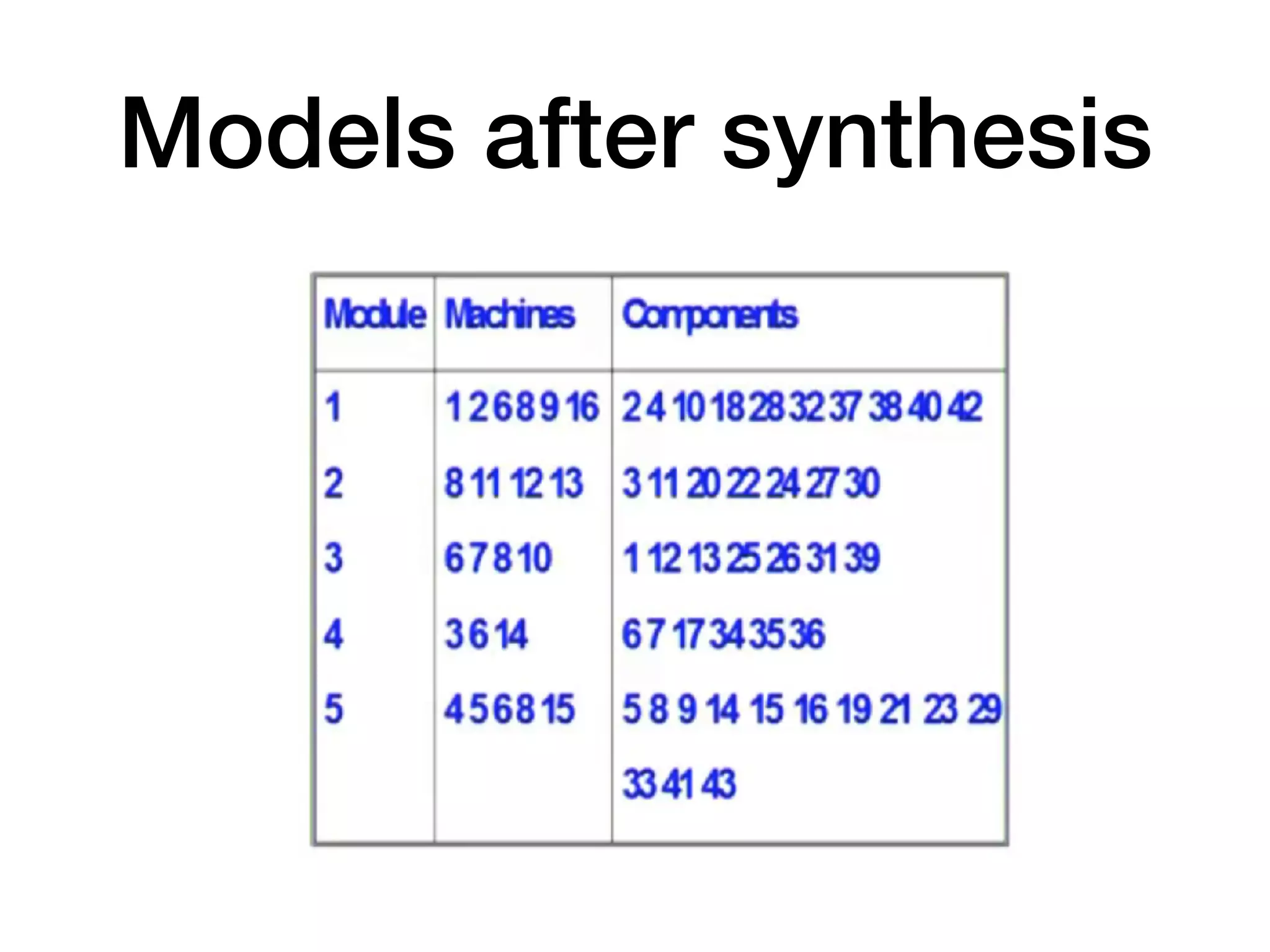

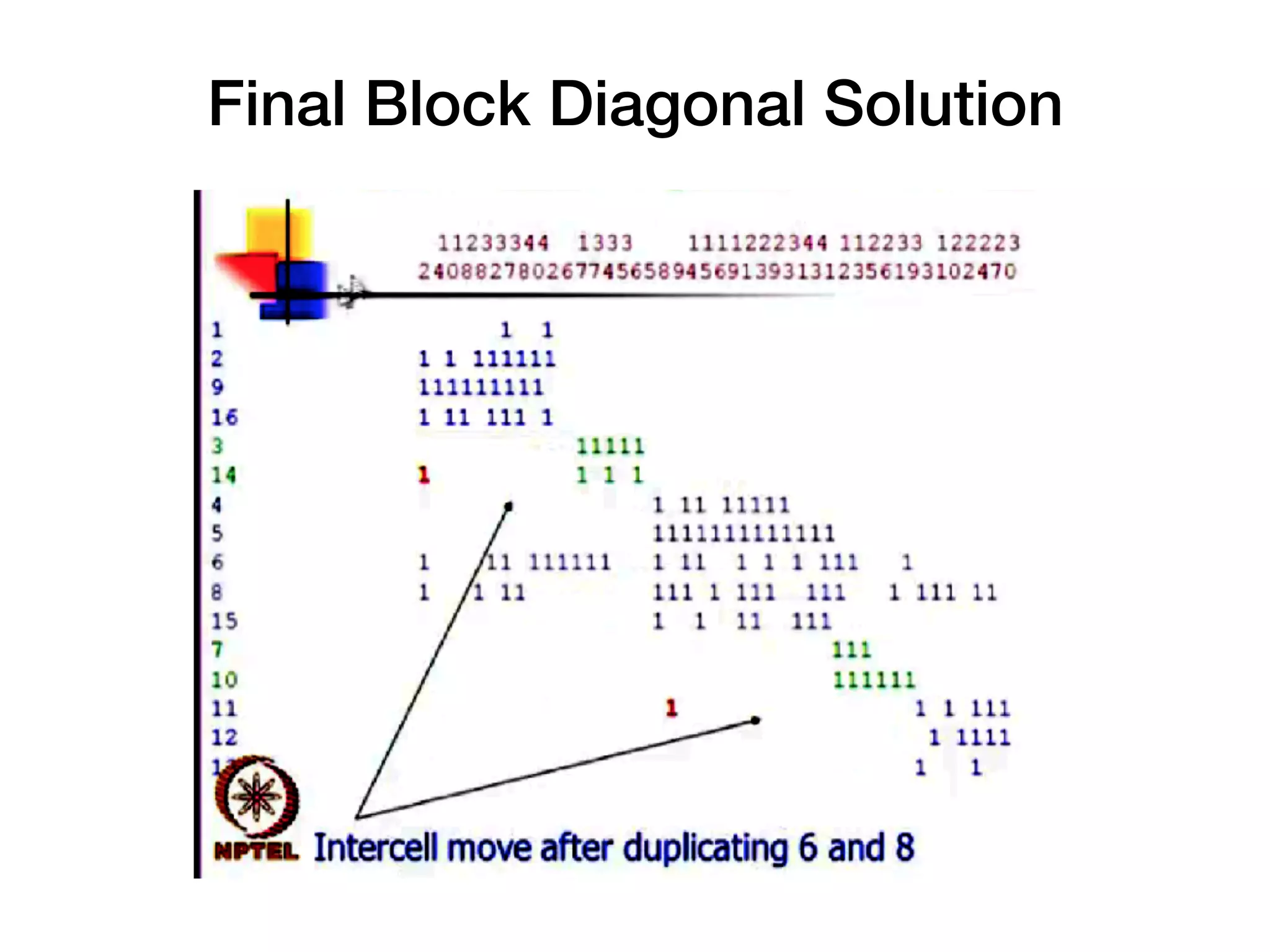

Group technology is a manufacturing approach where similar parts are grouped to optimize design and production processes, particularly in batch production. It utilizes Production Flow Analysis (PFA) to identify part families and aims to reorganize existing factory layouts into cellular layouts for efficiency. The document discusses the challenges and solutions for creating manufacturing cells, including the merging of modules and intercell movements, to reduce the number of machines required for production.