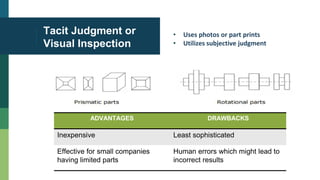

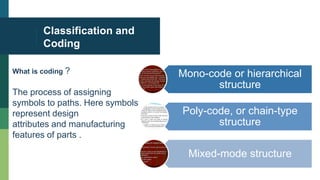

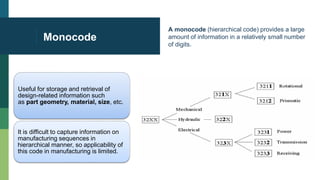

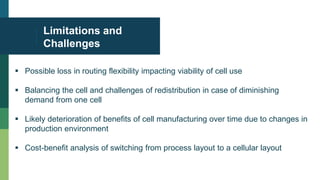

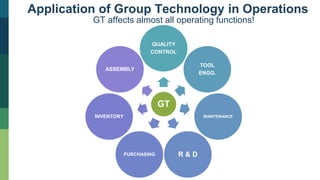

Group Technology is a manufacturing process that produces families of parts within a single production line or cell of machines. A manufacturing cell is a cluster of machines grouped together to produce a similar part family. Techniques like tacit judgment, visual inspection, classification and coding systems, and production flow analysis are used to form part families by identifying parts that require similar manufacturing processes or equipment. Rank order clustering analyzes a machine-part incidence matrix to group similar machines and components into production cells to minimize material handling needs. While cellular manufacturing offers benefits like reduced work-in-process inventory and lead times, it also faces challenges like loss of routing flexibility and difficulty balancing cells over time.