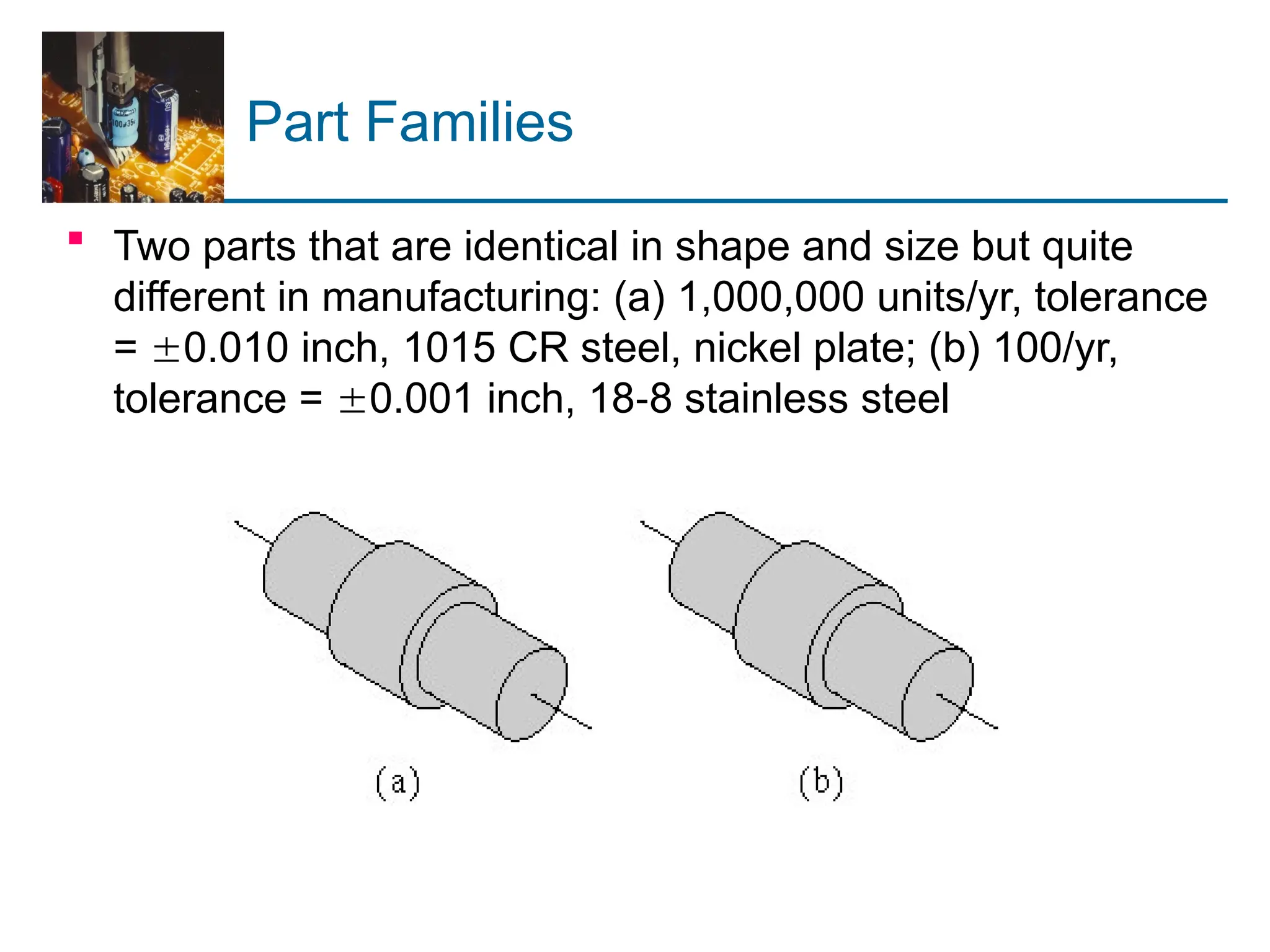

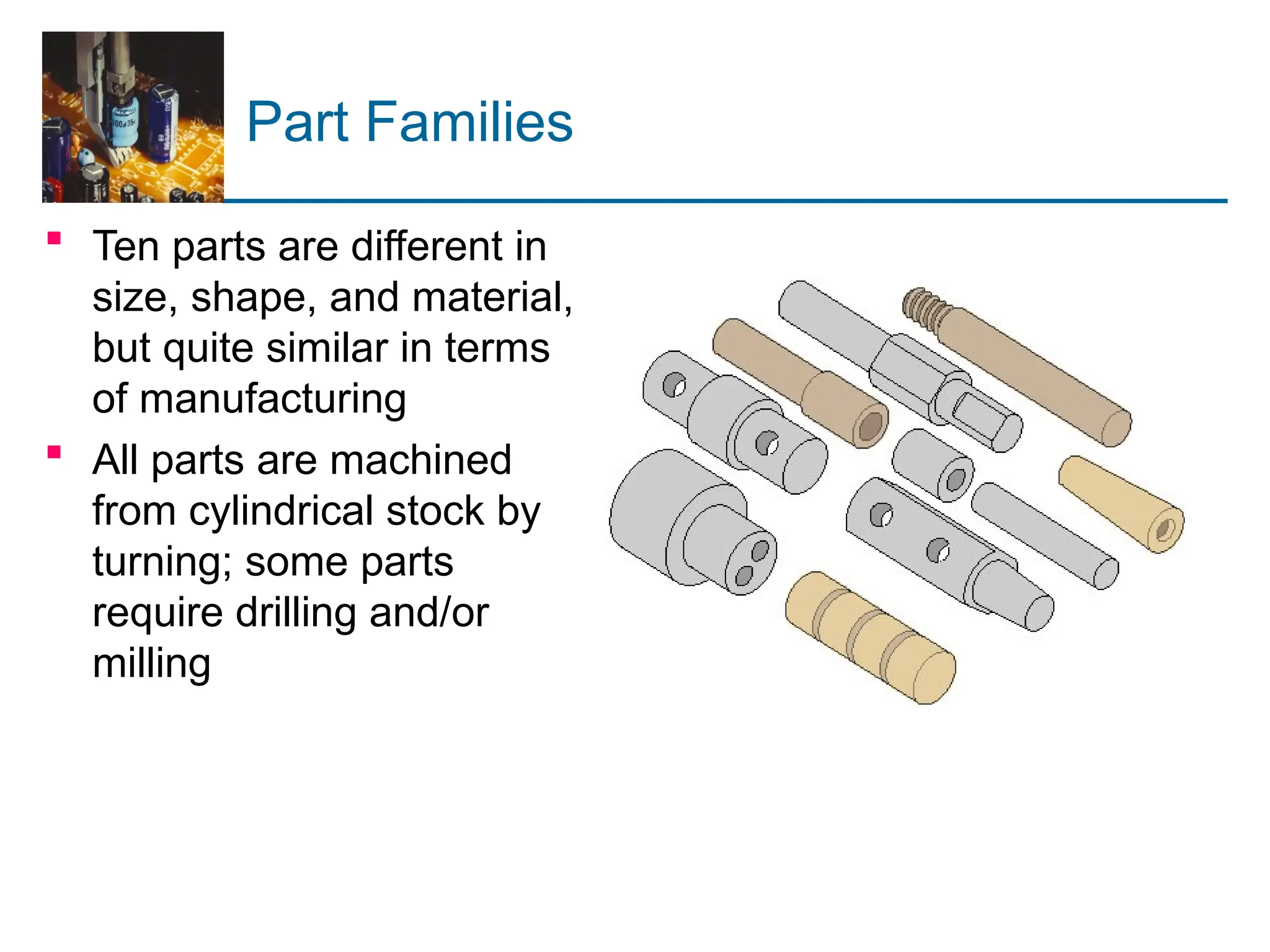

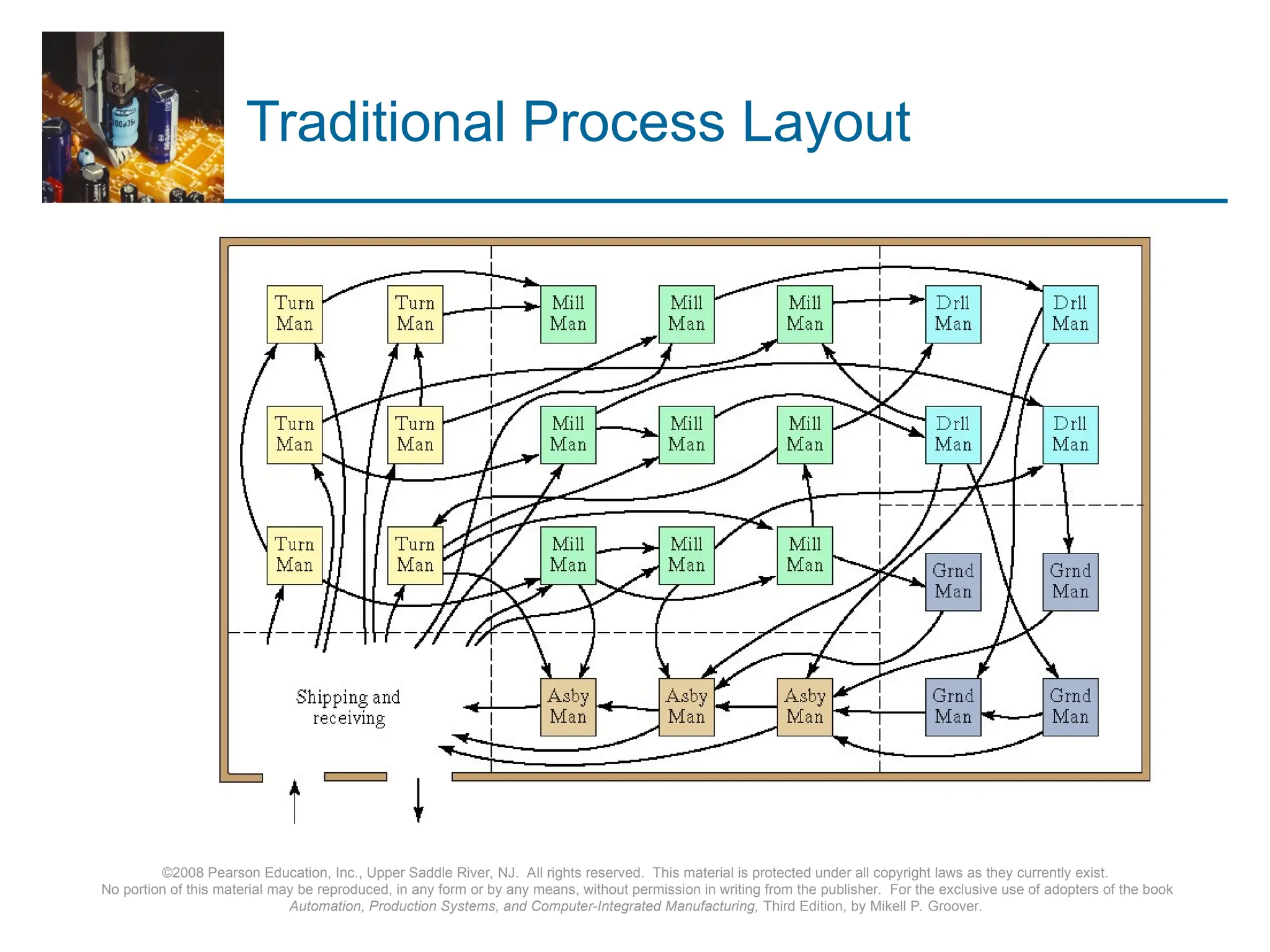

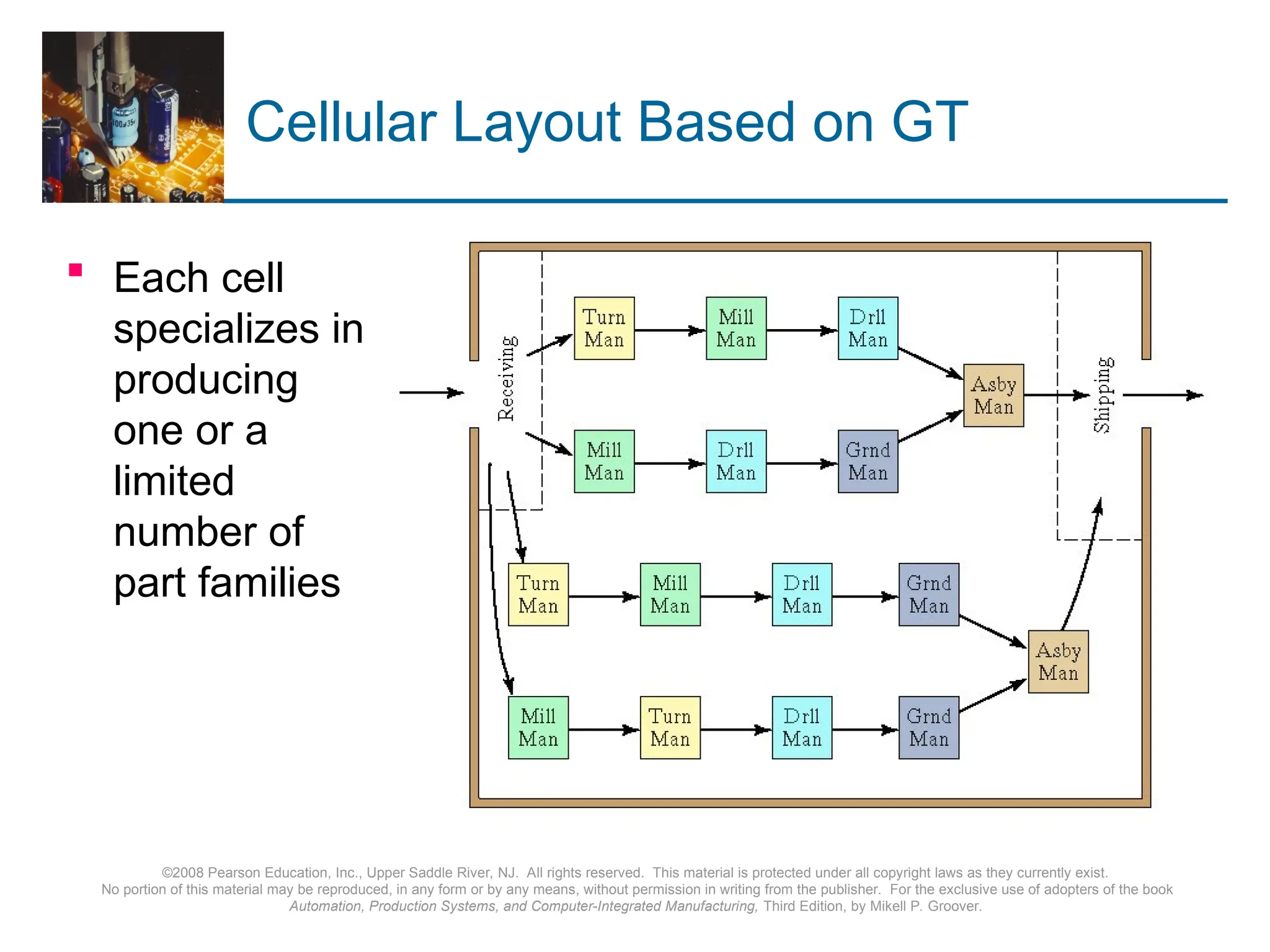

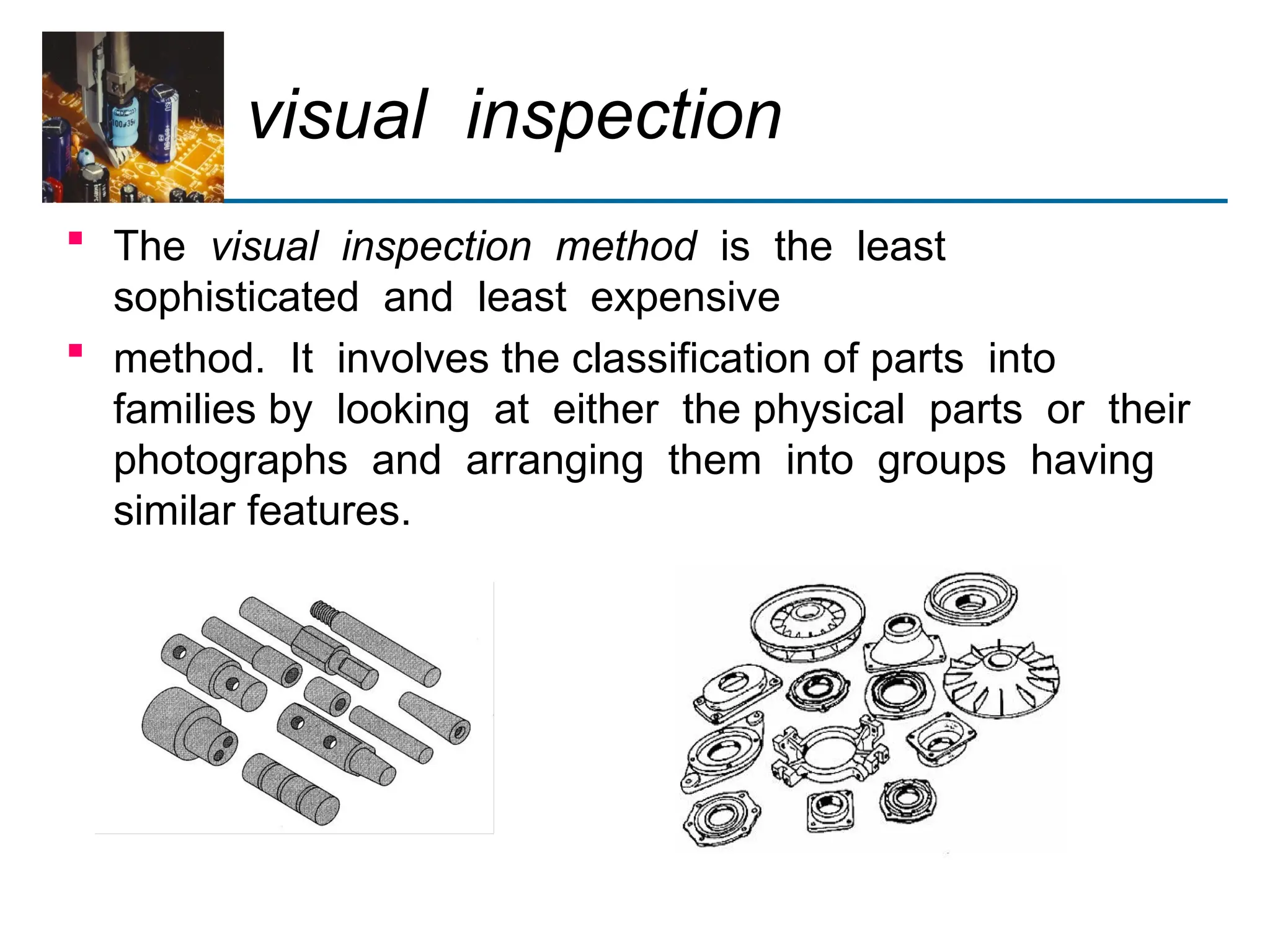

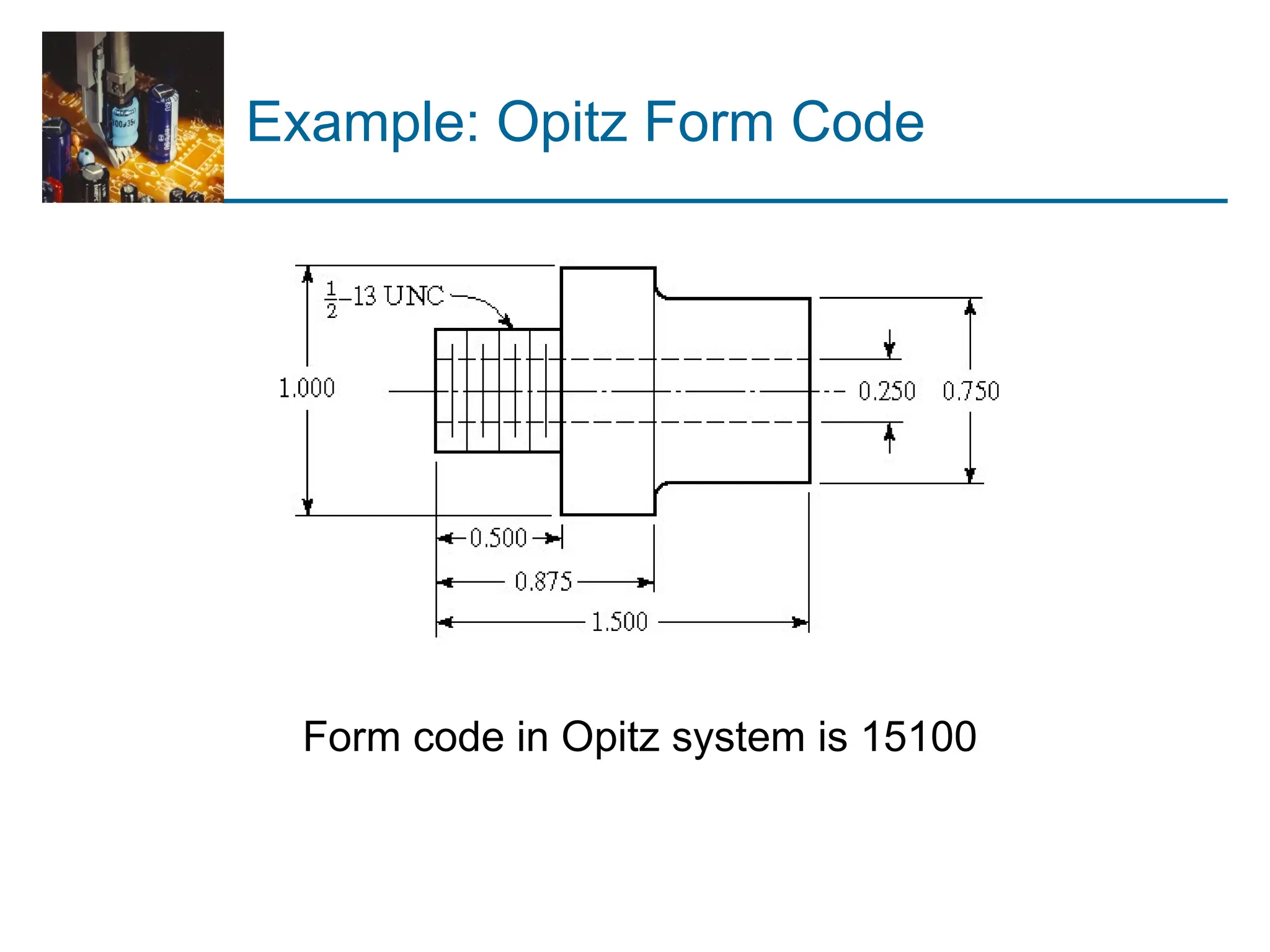

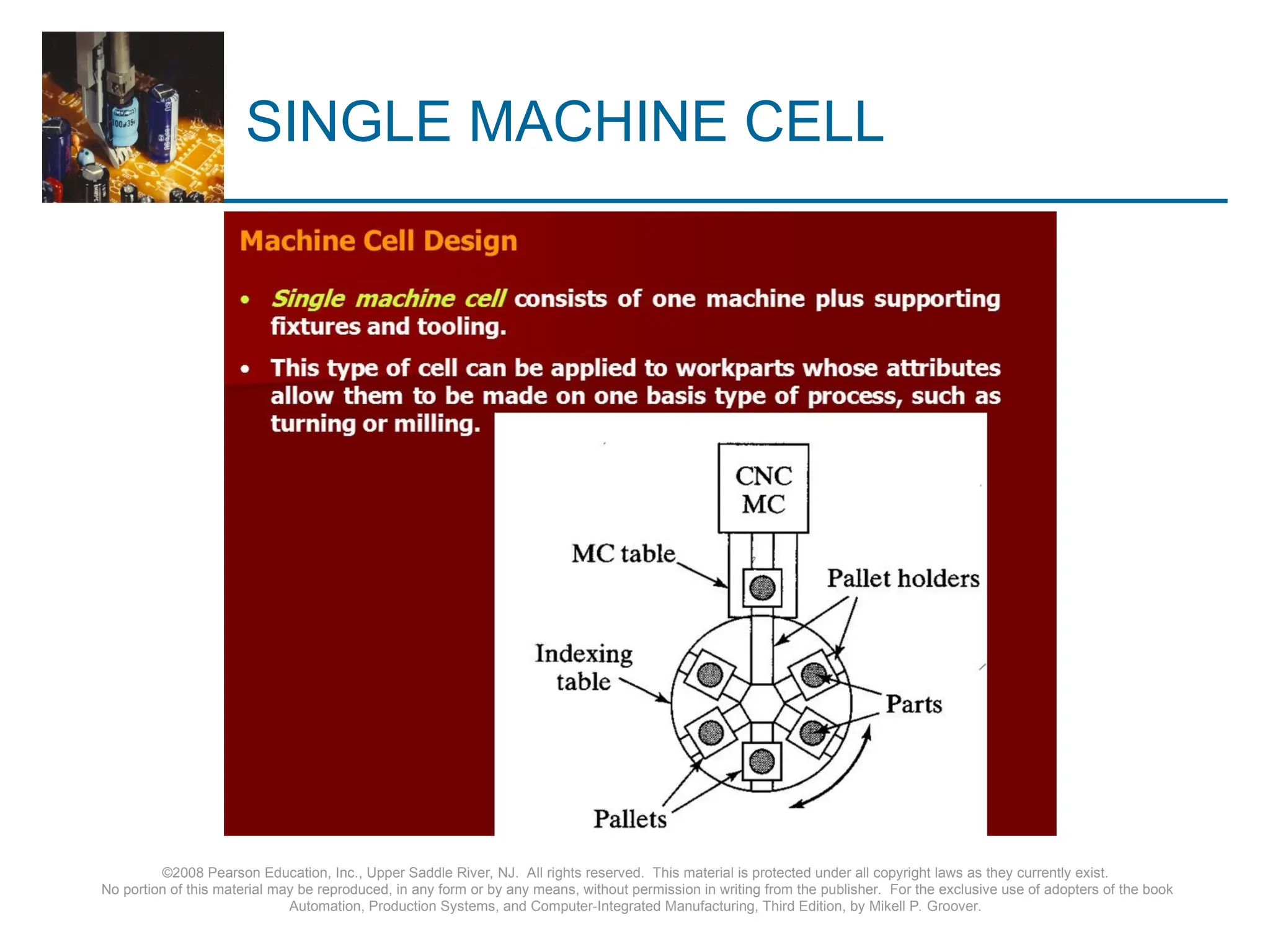

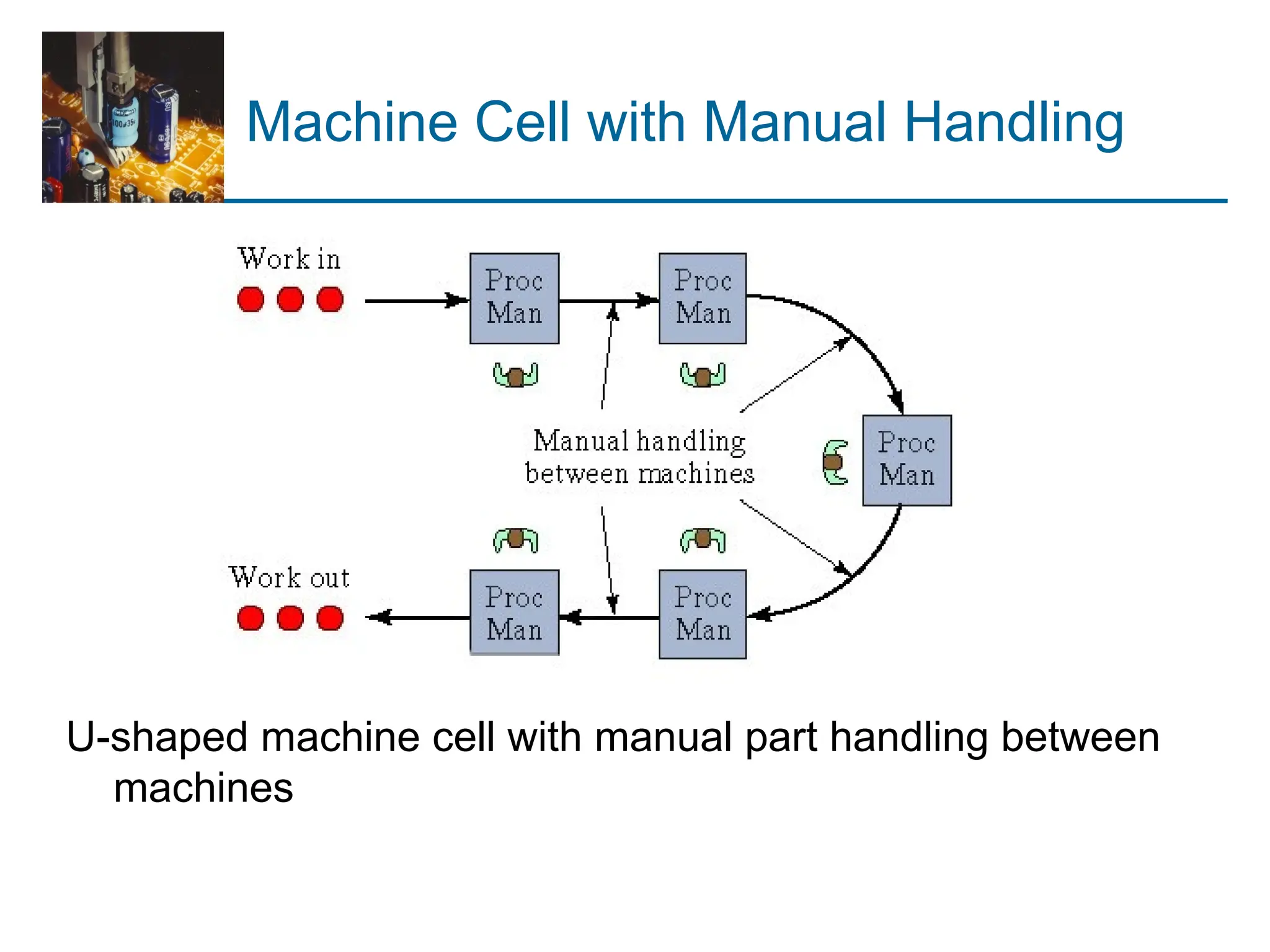

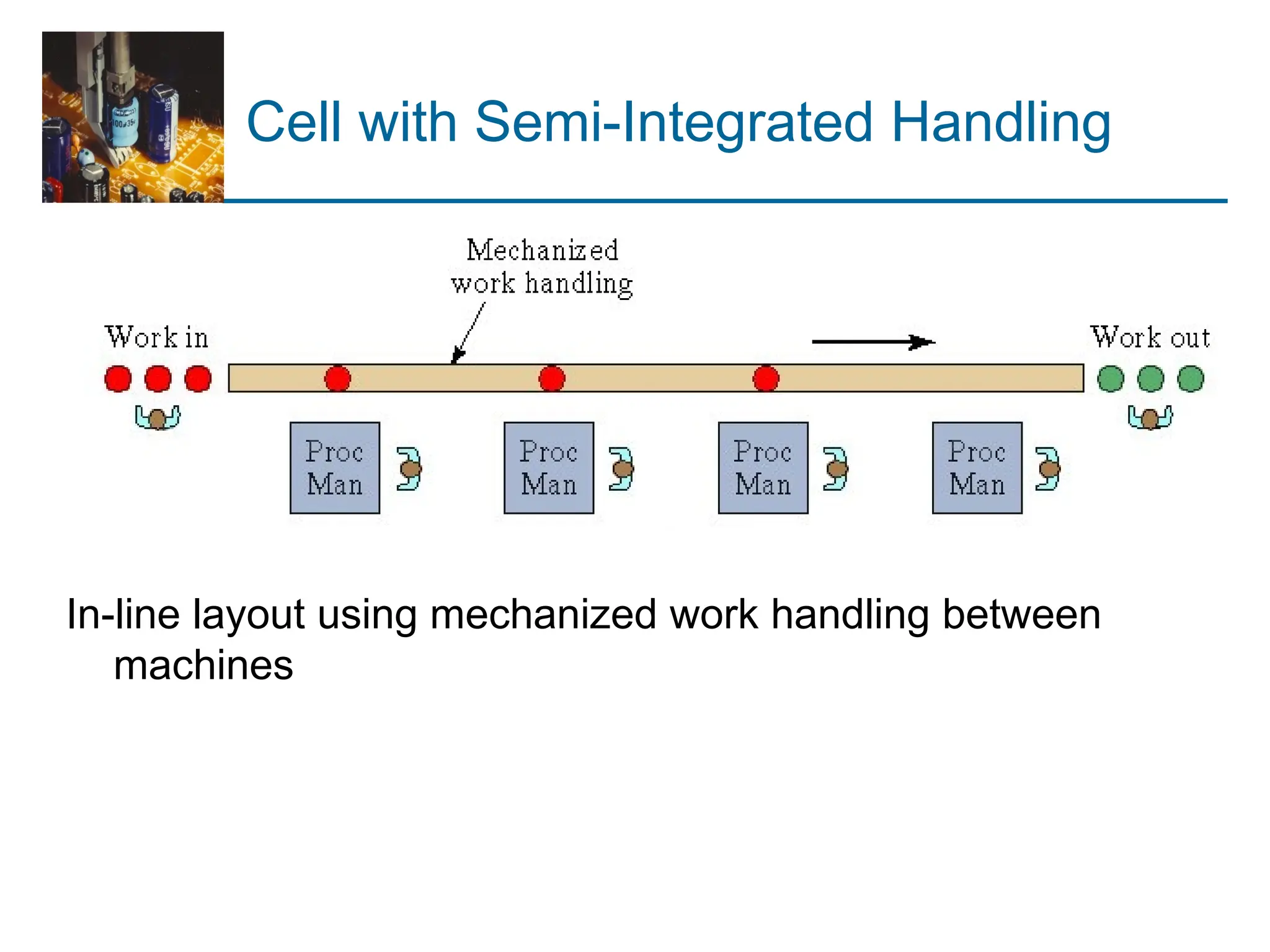

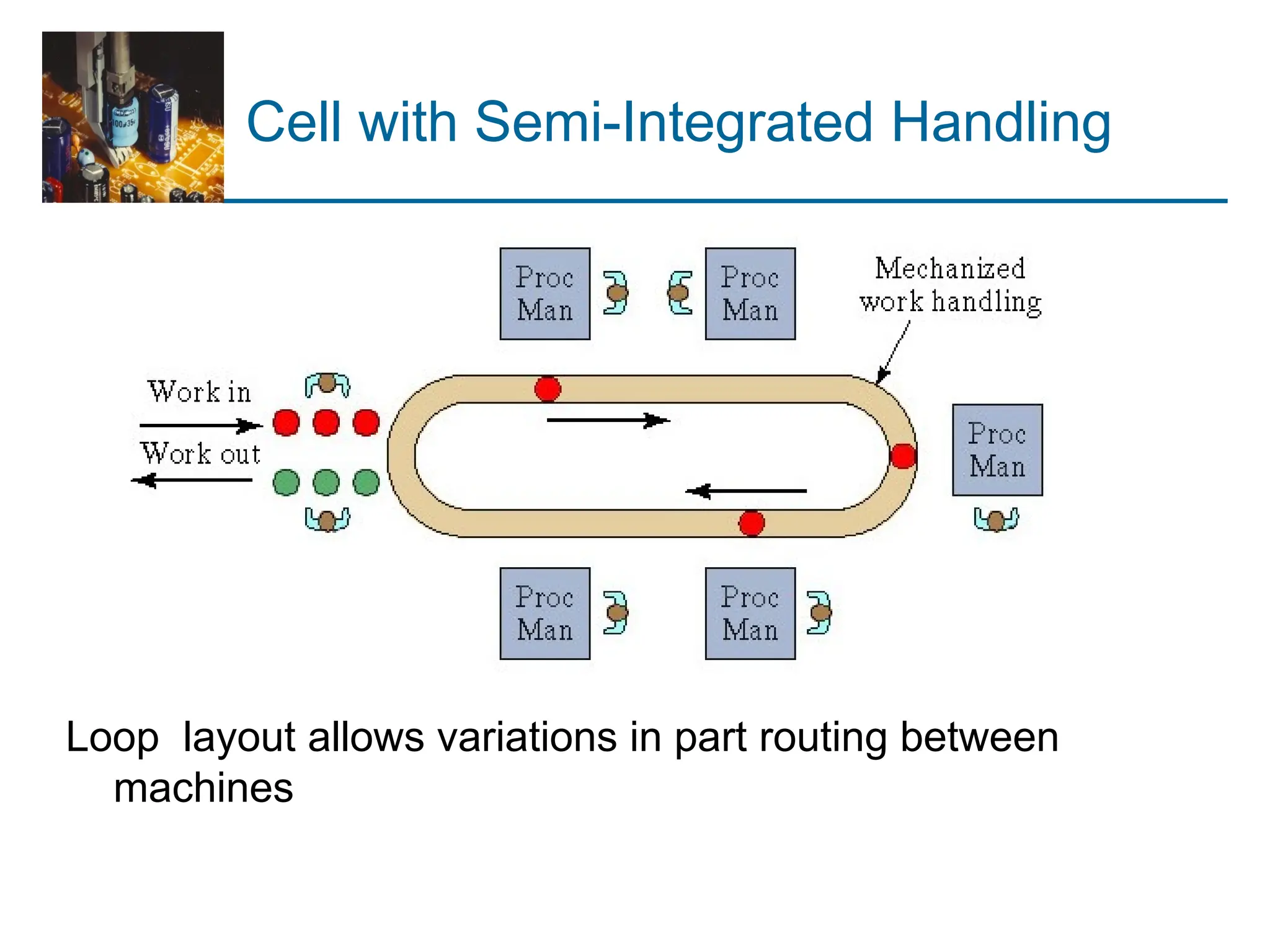

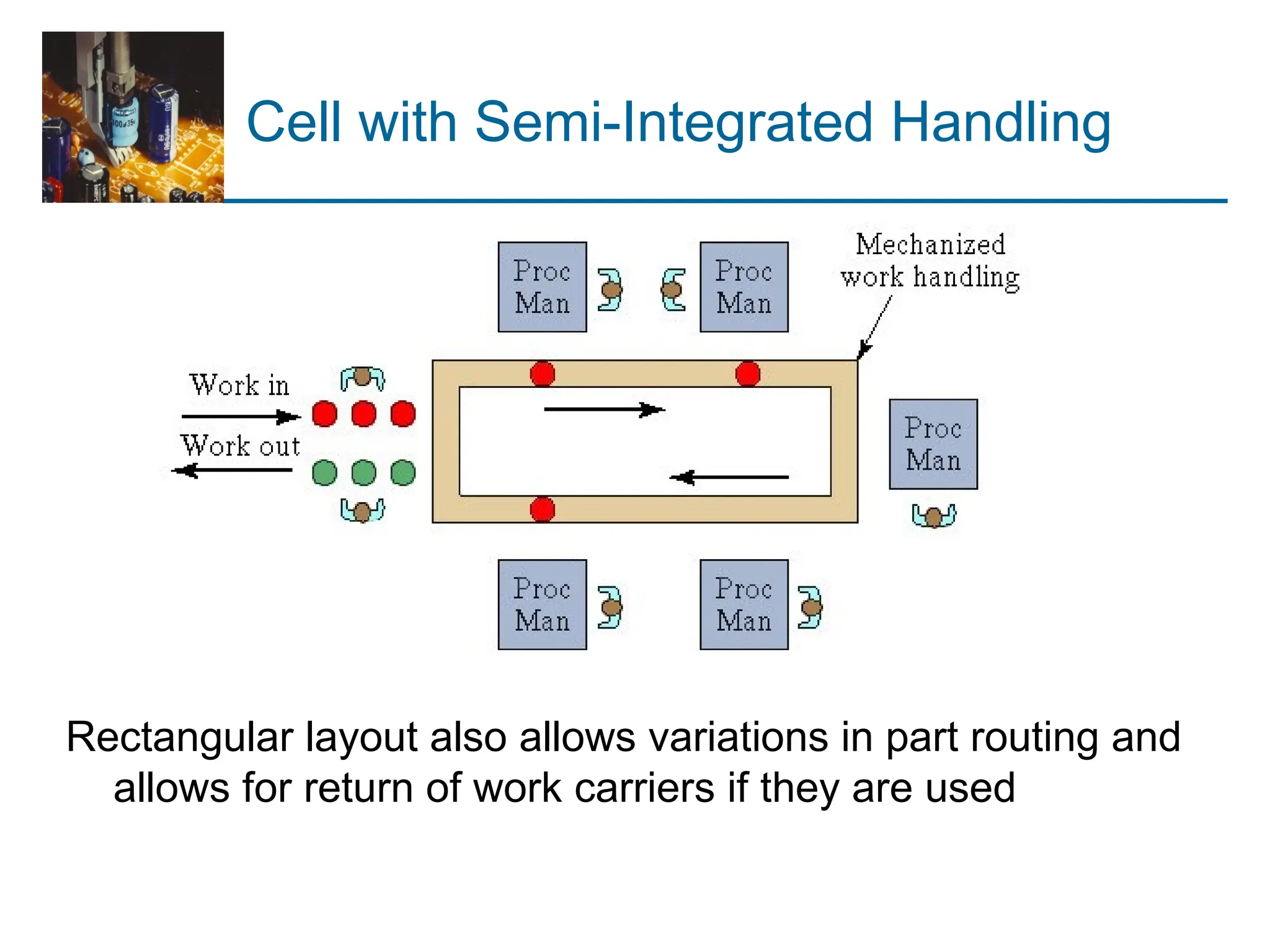

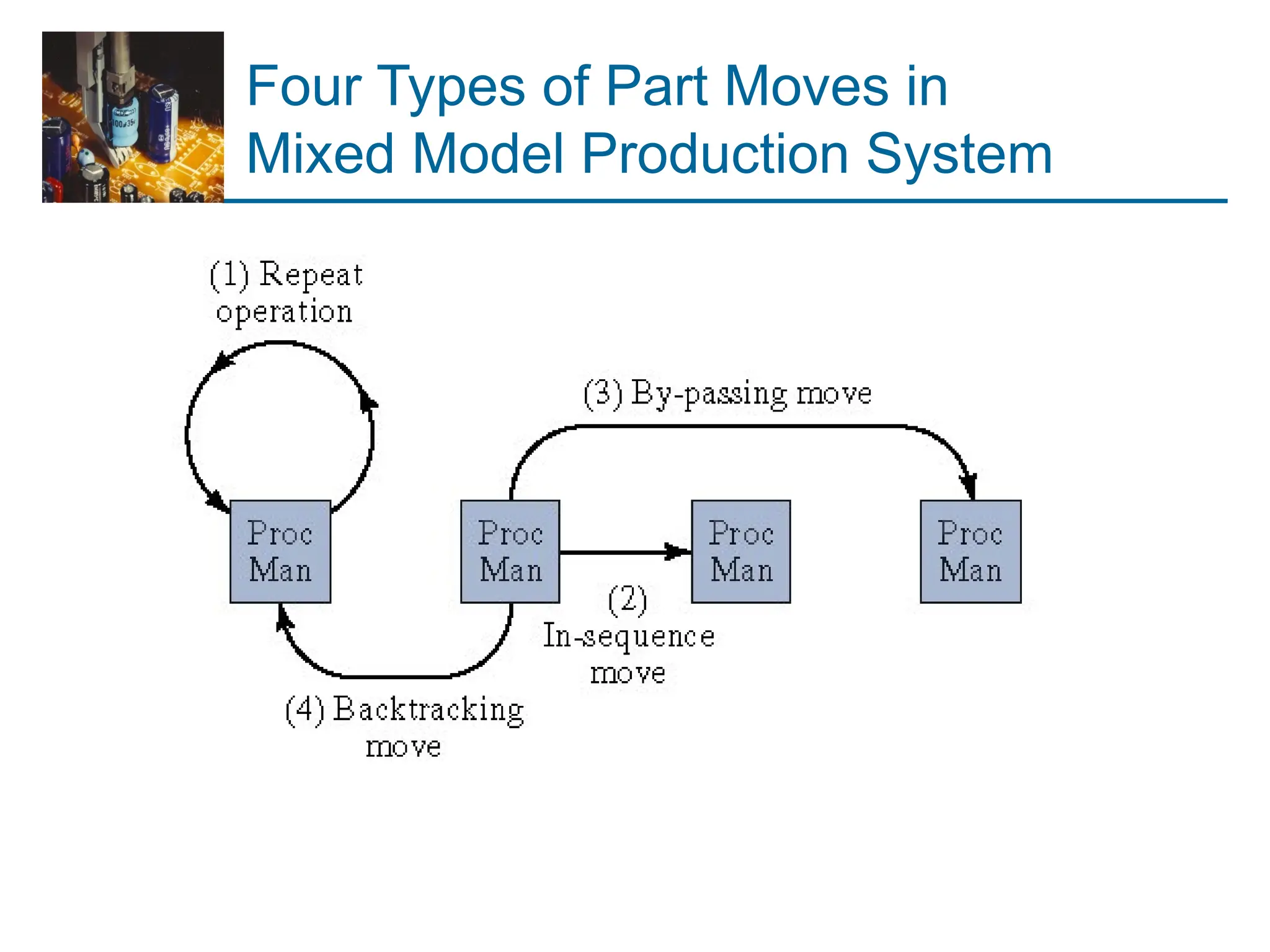

Group Technology (GT) is a manufacturing approach that organizes similar parts into families to streamline production and minimize waste through shared processing steps. It offers advantages like reduced setup times, improved quality, and more efficient inventory management, while also facing challenges in identifying and rearranging part families and production machines. Cellular manufacturing applies GT principles by grouping machines into cells, enhancing lead times, reducing work-in-process inventory, and simplifying scheduling.