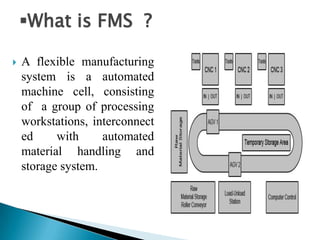

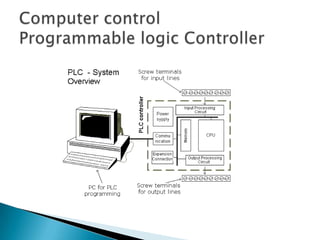

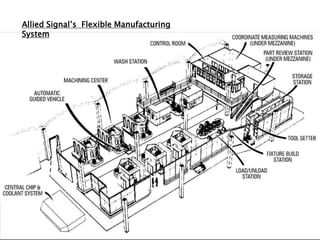

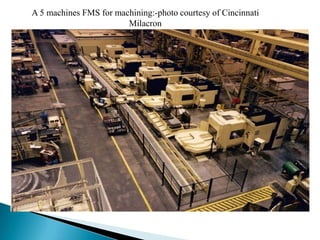

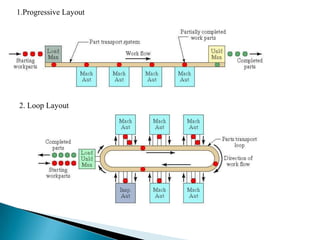

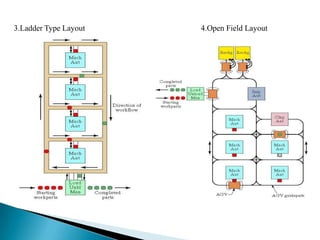

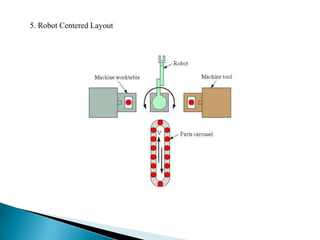

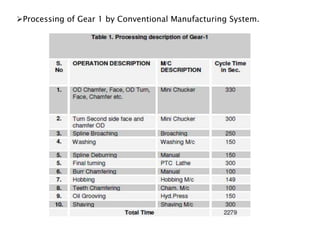

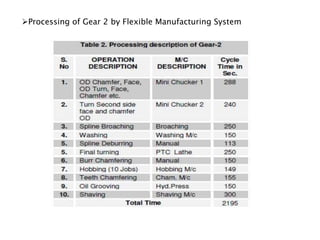

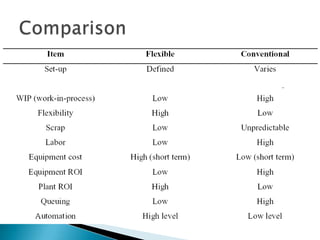

This document provides an overview of flexible manufacturing systems (FMS). It defines FMS as an automated machine cell consisting of interconnected processing workstations and automated material handling. It discusses the history and purpose of FMS in optimizing manufacturing cycle times and reducing costs. The basic components of FMS are described as workstations, automated material handling systems, and computer control systems. The document outlines different types of FMS layouts and how flexibility is achieved. It provides examples of FMS applications and discusses the advantages of FMS in improving efficiency and reducing production time, while also noting the high expenses associated with implementation.