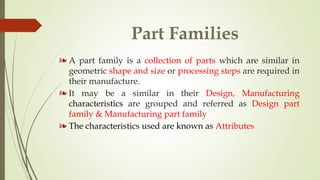

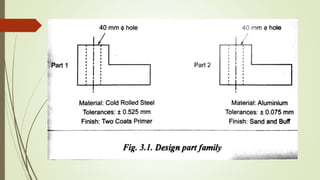

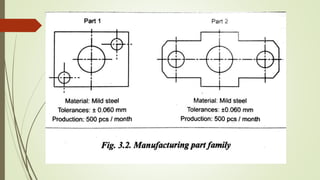

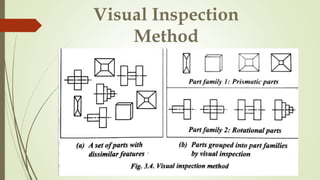

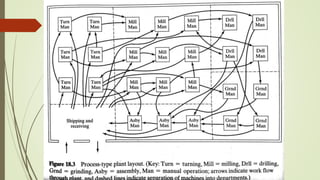

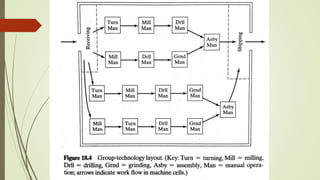

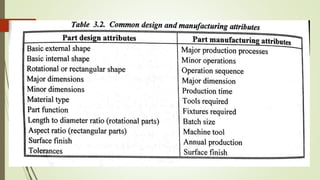

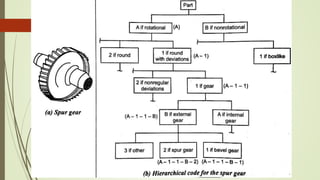

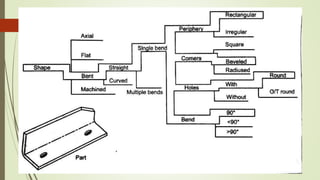

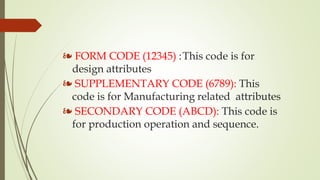

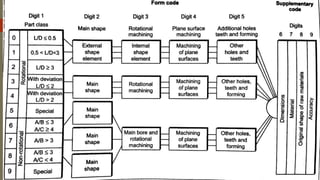

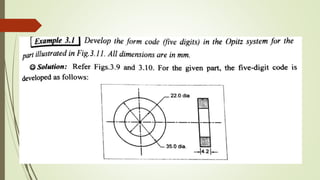

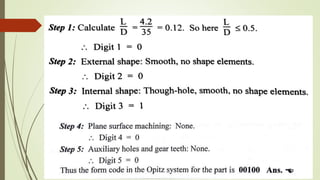

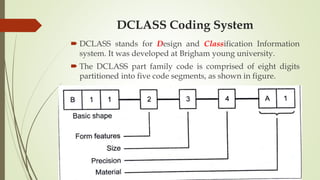

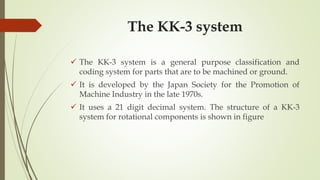

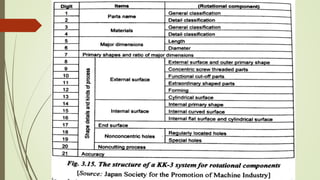

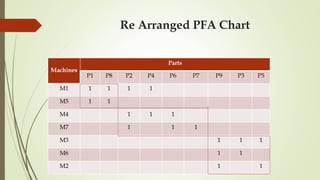

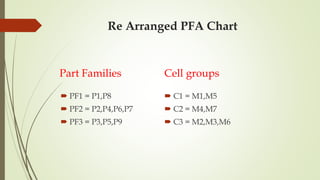

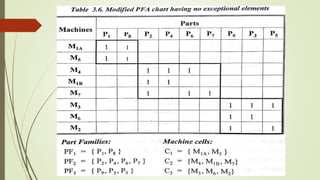

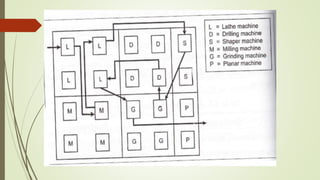

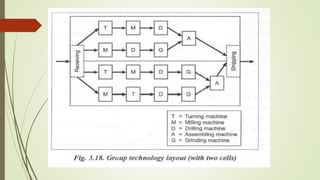

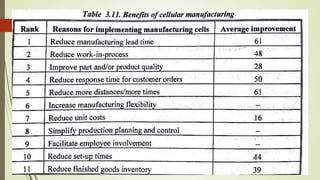

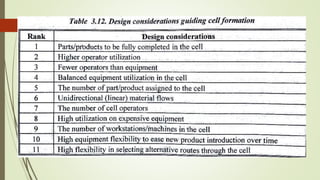

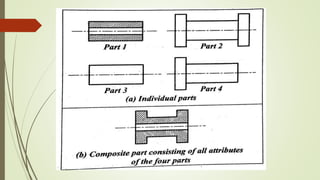

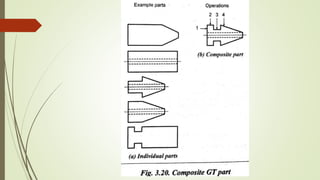

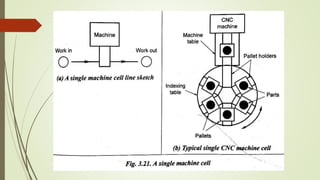

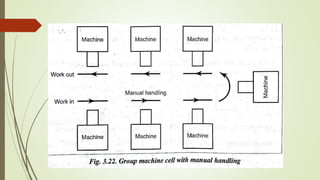

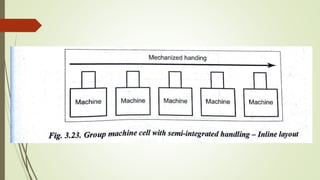

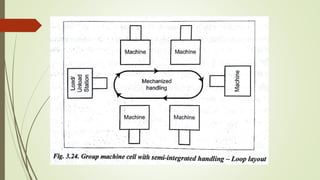

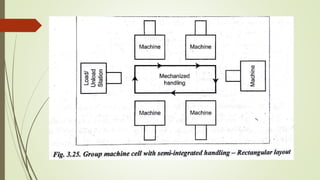

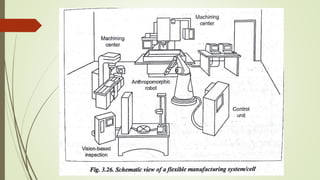

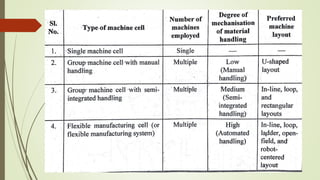

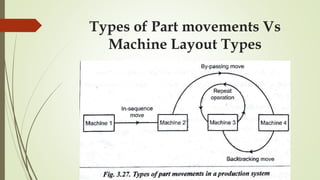

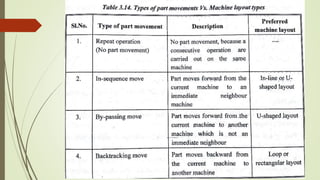

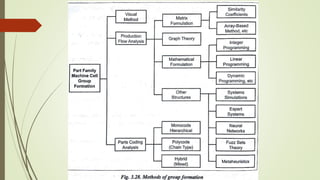

Group technology and cellular manufacturing aim to increase production efficiency by grouping parts and machines. Parts are classified into families based on their design and manufacturing attributes. Production flow analysis identifies part families and associated machine groupings. A composite part represents all attributes of a family. Machine cells are designed around part families, and can have single machines, manual handling, or integrated material handling between grouped machines arranged in line, loop, or rectangular layouts. Quantitative analysis helps optimize cell design factors like layout, production rate, and part routing.