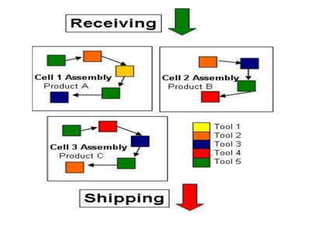

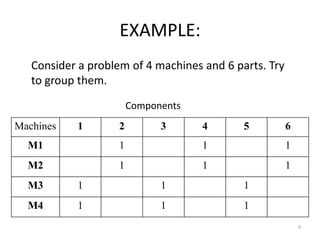

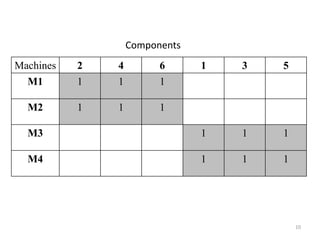

Group technology (GT) and cellular manufacturing involve organizing production around part families and machine cells. GT involves standardizing similar tasks, storing information about recurring problems, and performing similar activities together. Cellular manufacturing reduces flow times, inventories, and allows for rush orders. It involves analyzing machine-component relationships and grouping machines and parts into cells. Benefits of GT and cellular manufacturing include reduced setup times, work in process, defects, and costs as well as improved material flow and customer service.