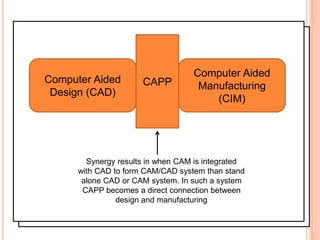

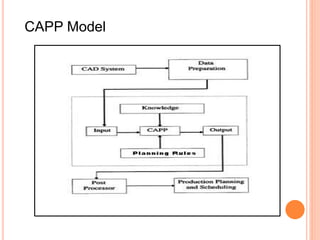

Computer Aided Process Planning (CAPP) integrates computer technology with manufacturing to create efficient production plans from design concepts. It serves as a crucial link between CAD and CAM, optimizing manufacturing processes based on various variables such as costs and equipment availability. CAPP can be implemented through manual experience or advanced programming languages to improve overall quality, scheduling, and cost estimation in manufacturing.