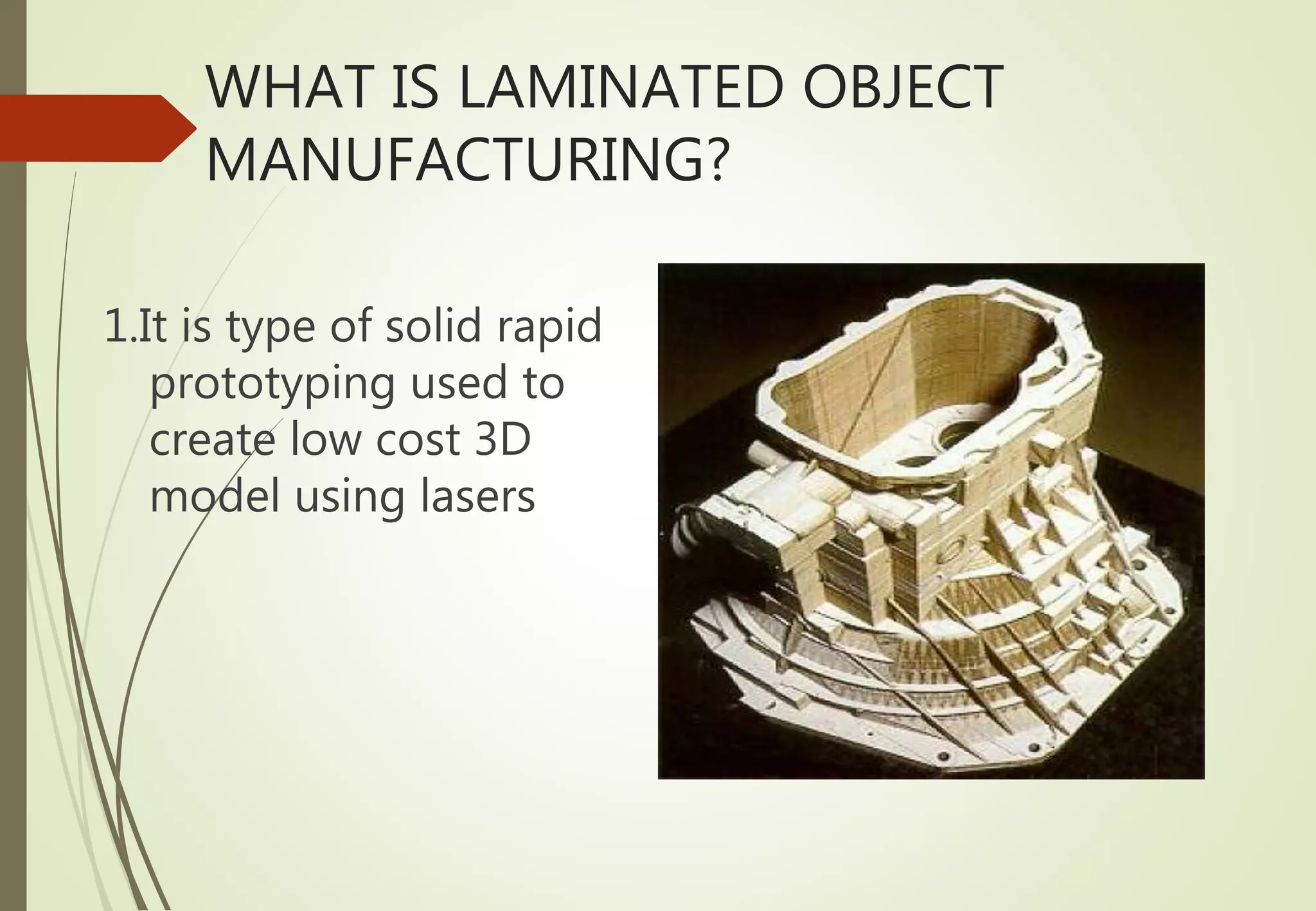

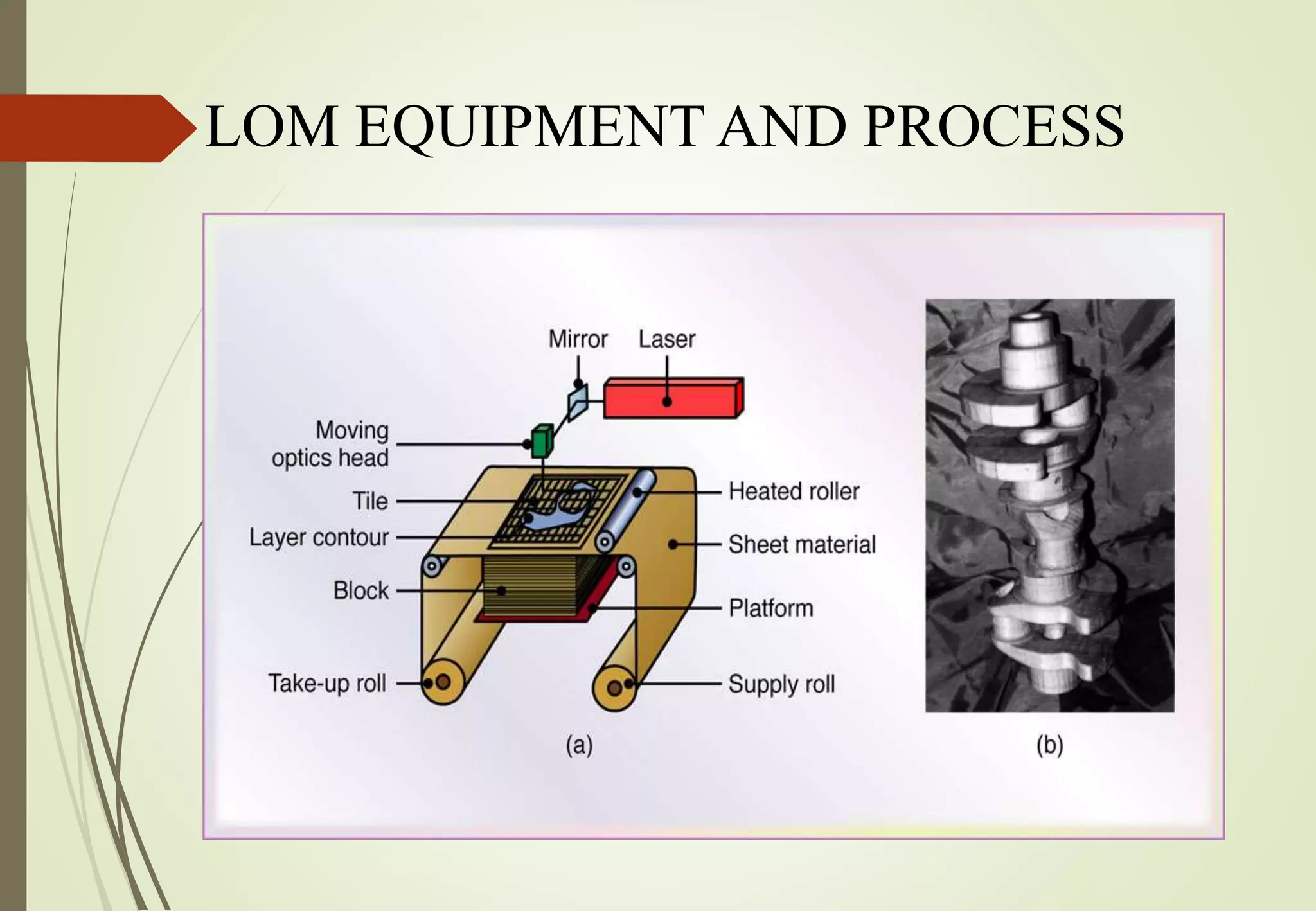

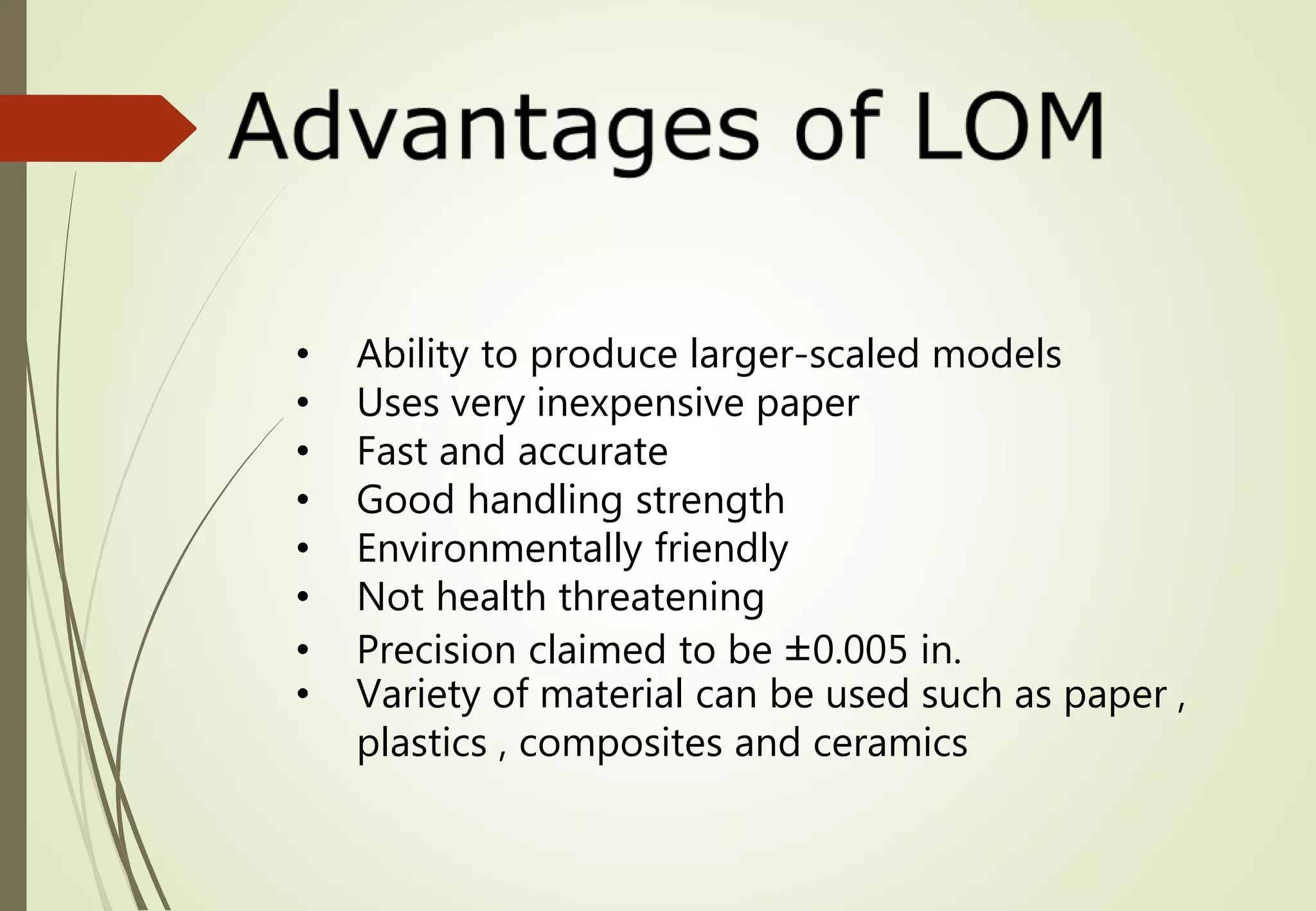

The document discusses Laminated Object Manufacturing (LOM), a type of solid rapid prototyping that uses lasers to create 3D models from layered materials. The LOM process involves adding and subtracting layers of material such as paper or plastic to build a part. Each thin layer is cut to shape using a CO2 laser before the next layer is added. LOM can produce models and prototypes quickly and cheaply from a variety of materials and is used to make scaled models, patterns for casting, and 3D printed objects for home use. However, LOM also has disadvantages like using unstable paper and producing smoke during cutting.