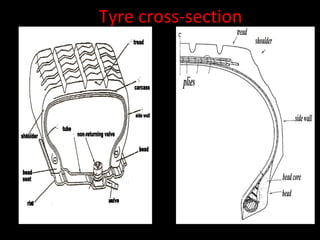

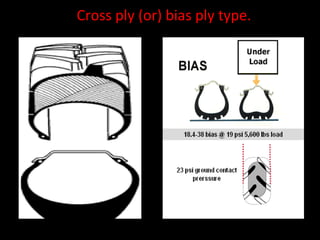

This document discusses the key components and functions of automobile tires. It describes the different types of tire casings, including cross-ply, radial, and belted bias ply tires. Radial tires provide advantages like greater shock absorption, lower rolling resistance, and better steering characteristics compared to cross-ply or bias ply tires. The document also outlines the various materials used in tire construction, factors that affect tire life, common tire issues, and the tire manufacturing process.