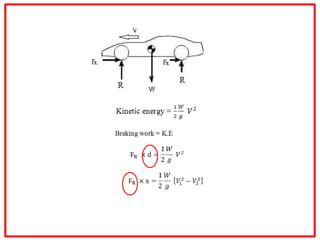

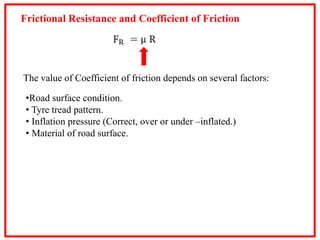

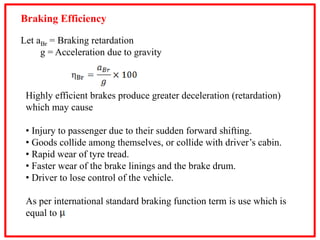

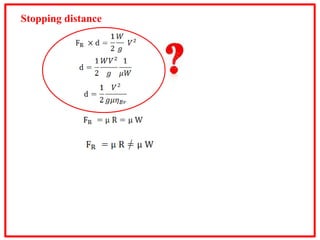

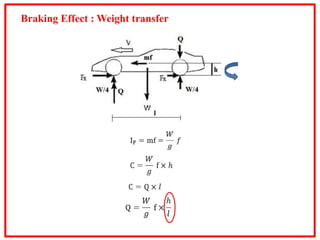

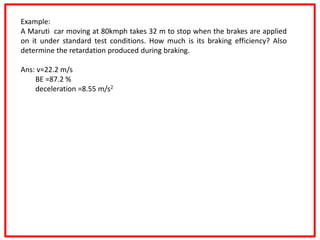

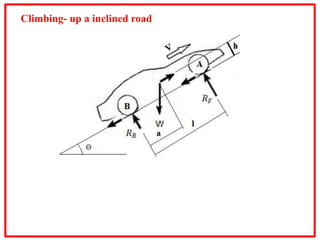

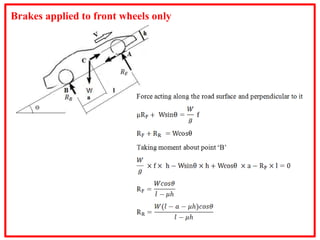

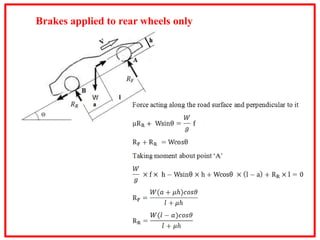

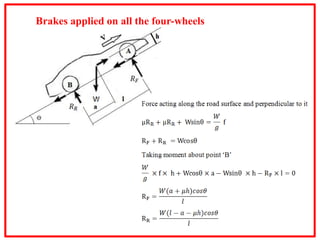

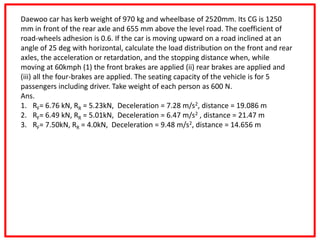

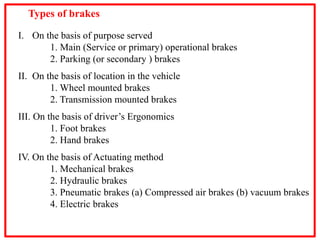

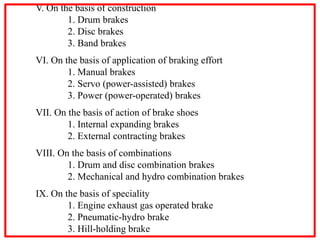

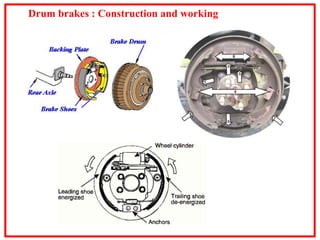

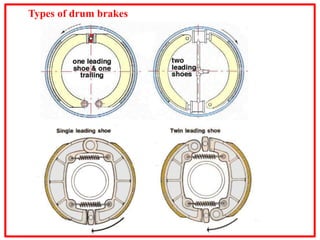

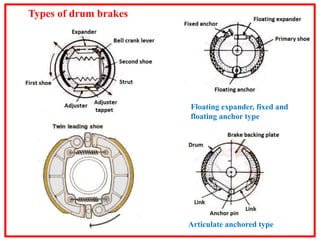

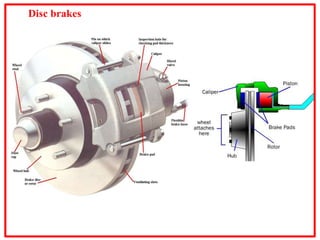

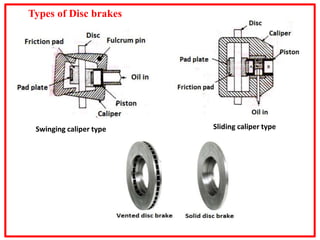

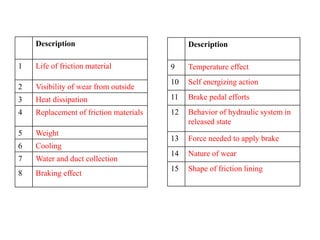

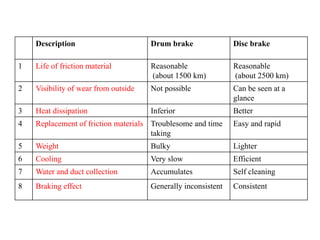

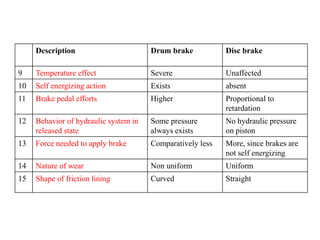

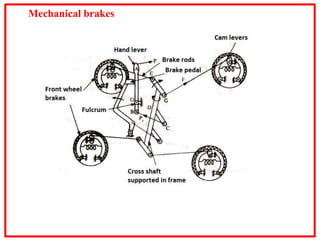

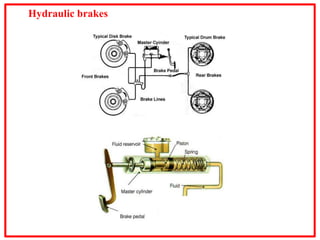

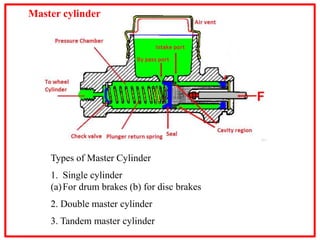

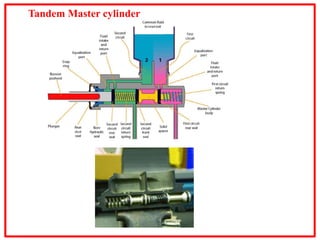

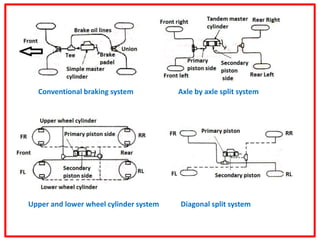

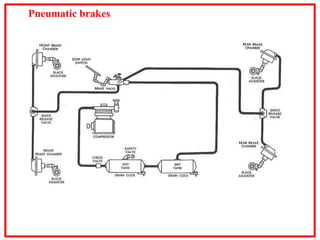

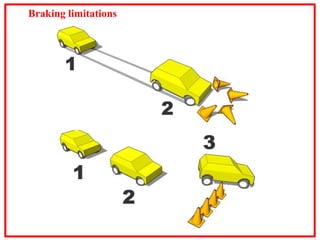

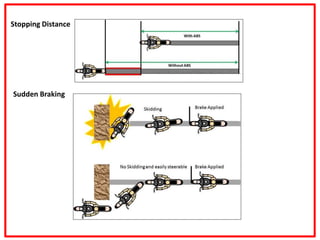

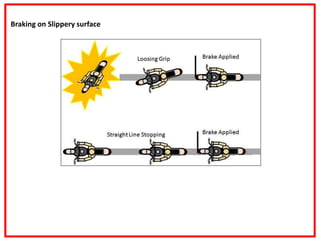

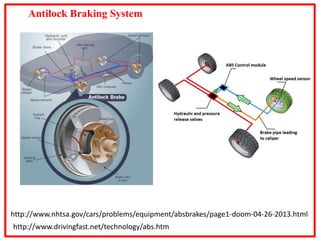

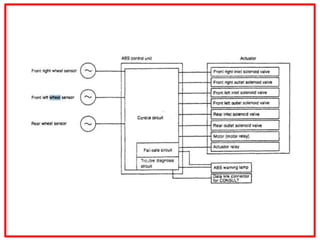

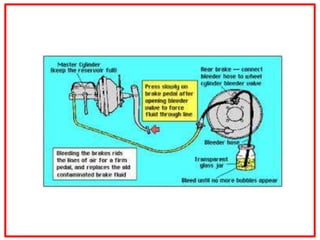

This document discusses various aspects of brakes and braking systems. It covers principles of braking like braking distance, efficiency and weight transfer. It describes different types of brakes based on location, actuation method, construction and application of braking effort. Specific brake types discussed include drum brakes, disc brakes, mechanical brakes, hydraulic brakes and pneumatic brakes. The document also covers topics like master cylinders, antilock braking systems, braking limitations and factors affecting stopping distance.