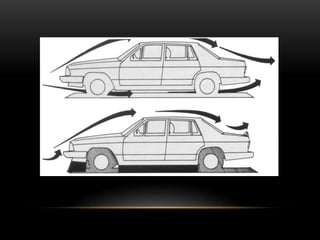

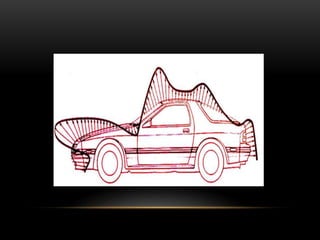

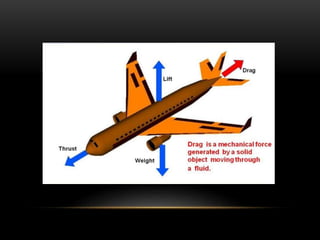

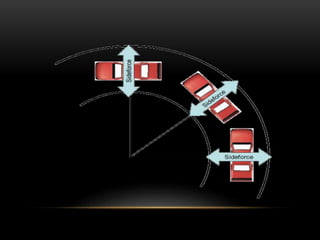

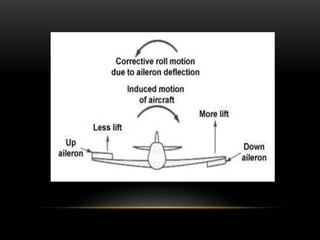

This document discusses vehicle aerodynamics and the various road loads that affect a vehicle's performance and fuel efficiency. It covers topics such as aerodynamic drag, lift forces, pressure distributions, rolling resistance, and how factors like air density, drag coefficients, tire design and crosswinds influence a vehicle's handling and energy usage. The goal of vehicle aerodynamics is to optimize these elements to reduce wind resistance, improve stability, and minimize fuel consumption during driving.