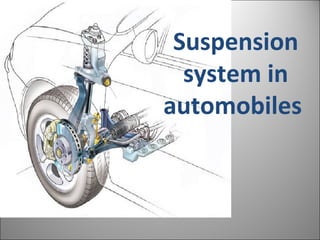

The suspension system connects a vehicle to its wheels using springs, shock absorbers, and linkages. It serves two main purposes - contributing to handling and braking, and protecting the vehicle and passengers from road shocks. Common suspension types include independent front suspensions like MacPherson struts and solid rear axles with leaf springs. Proper suspension provides cushioning, stability, and ride comfort while preventing excess body movement.