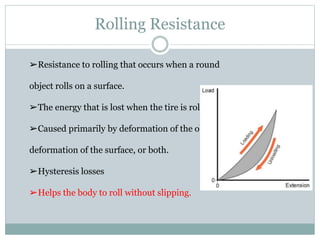

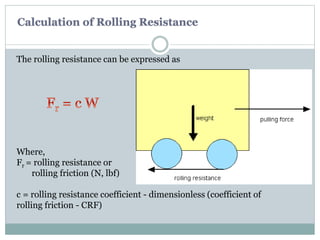

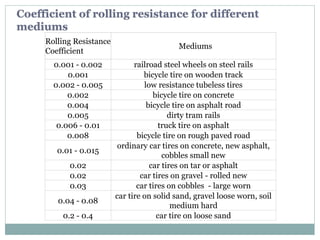

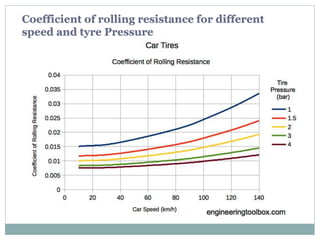

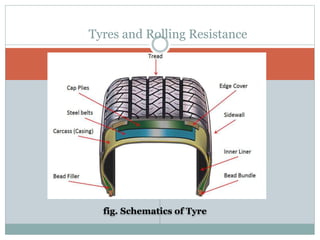

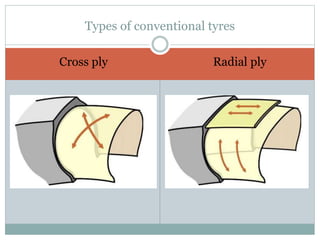

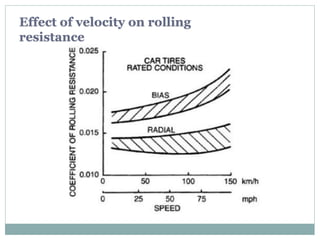

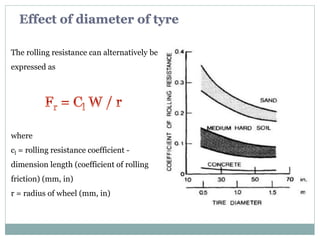

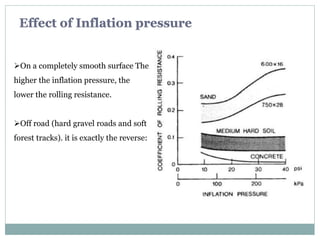

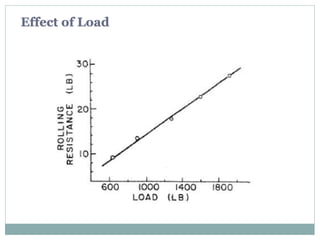

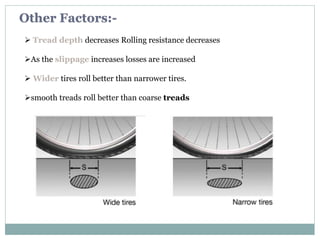

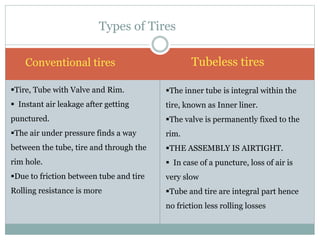

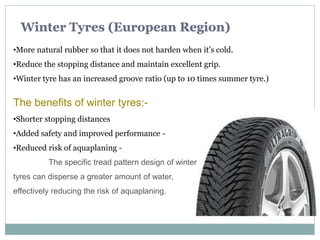

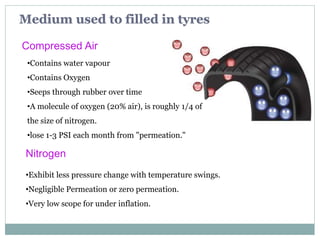

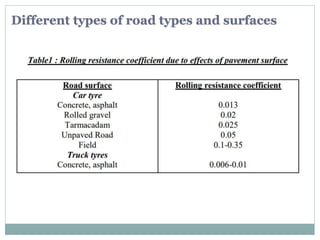

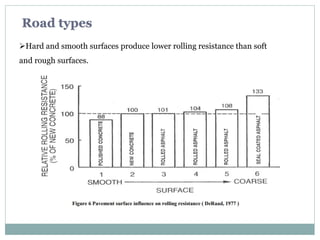

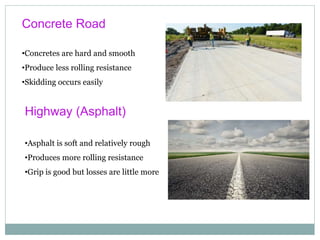

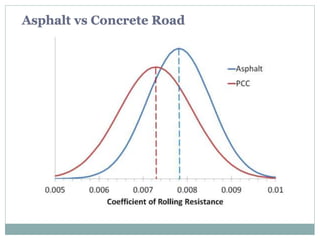

Rolling resistance is the energy lost when an object rolls over a surface. It is caused by deformation of the object and surface and hysteresis losses. The rolling resistance coefficient varies based on factors like surface type, tire type and condition, speed, load, and inflation pressure. Different tire types include summer, winter, and all-season tires suited for different weather conditions. Tire construction, materials, tread patterns, and wheel type also impact rolling resistance. Minimizing rolling resistance improves fuel efficiency.