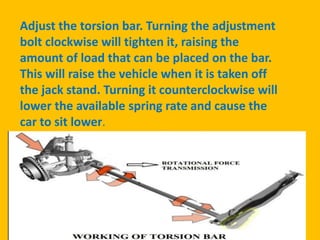

Torsion bars are metal bars used in automobile suspension systems that perform the function of springs. One end of the bar is fixed to the vehicle frame, while the other end is attached to components like the axle or control arm. When forces from driving cause the attached components to twist the bar, it provides resistance like a spring, absorbing shocks from the road. Torsion bars offer benefits like a soft ride, long durability, easy adjustability of vehicle height, and a compact design requiring less interior space compared to coil springs. However, they do not provide progressive spring rates and ride quality can become harsh when adjusted to maximum height. Torsion bar suspension systems are commonly used on trucks, SUVs, and military vehicles.