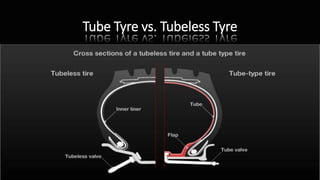

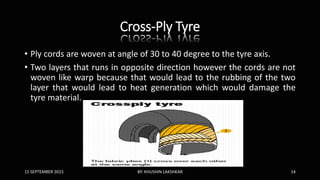

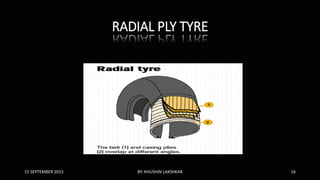

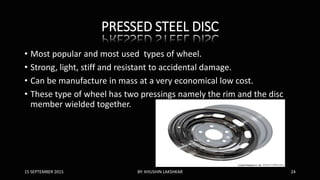

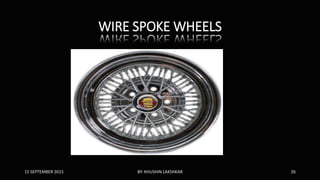

Khushin Lakshkar completed a summer internship at Khandelwal Motor Agencies in Mathura, where he studied wheels and tyres. His report discusses the differences and functions of wheels and tyres, describing tyre construction methods like tube and tubeless tyres. It also covers tyre properties, classifications including radial and bias ply construction, and maintenance like rotation and inspection. Wheel requirements and types including pressed steel, spoked, and light alloy wheels are also summarized.