This document discusses different types of tires. There are two main types - tubed tires which have an inner tube, and tubeless tires which do not have an inner tube. Tubeless tires have advantages like lesser weight, better cooling, lower rolling resistance, and more comfortable ride.

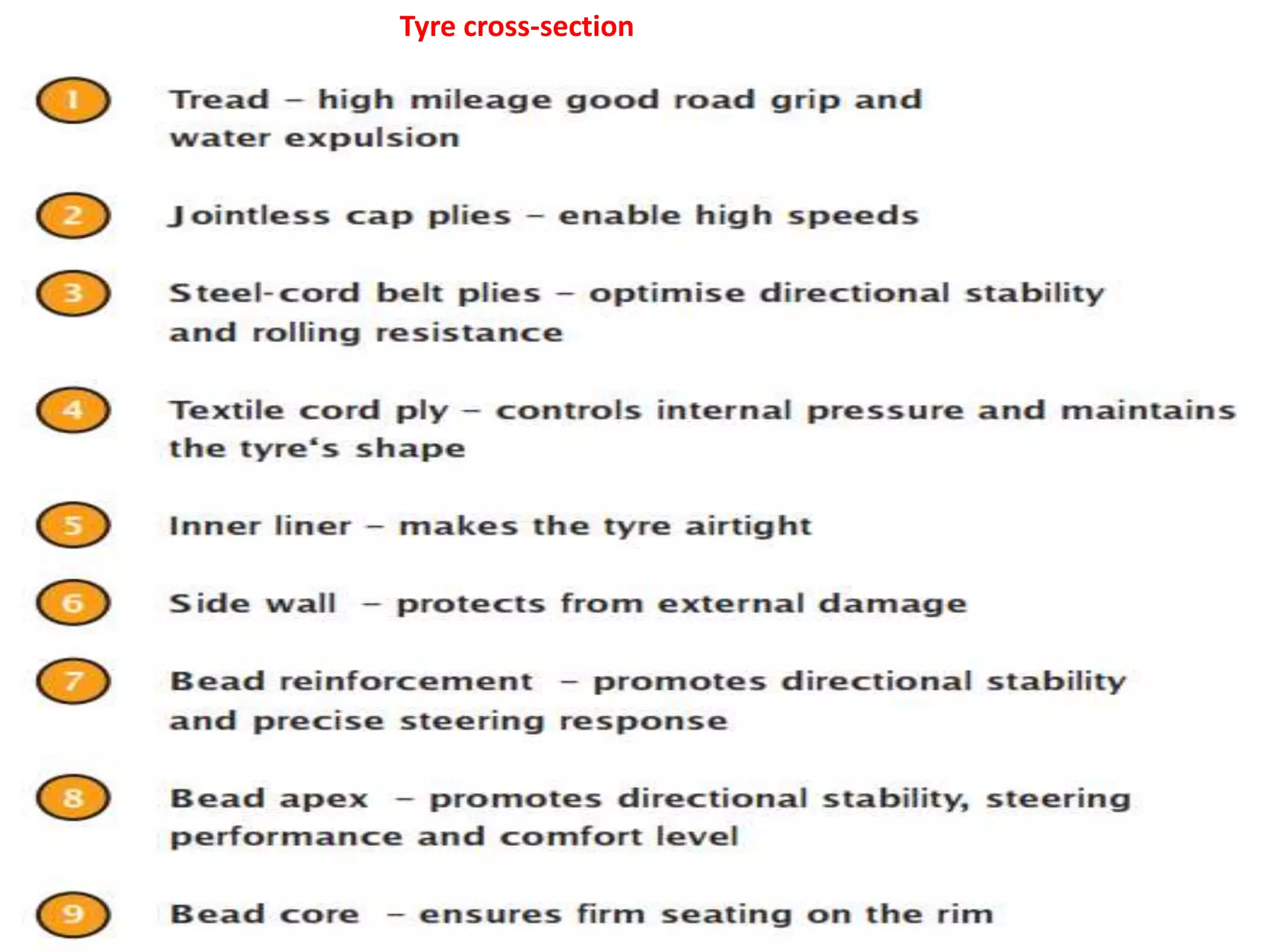

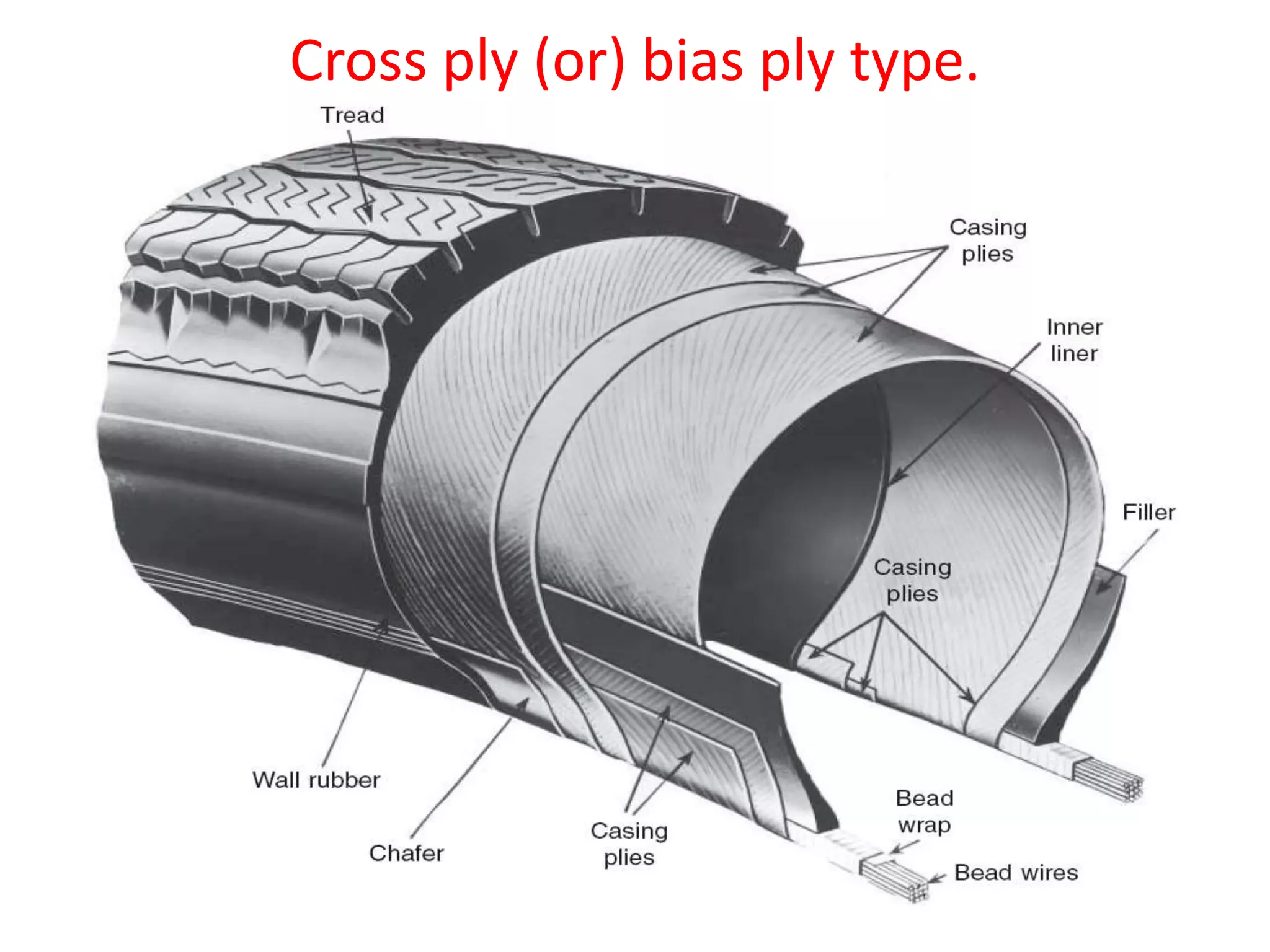

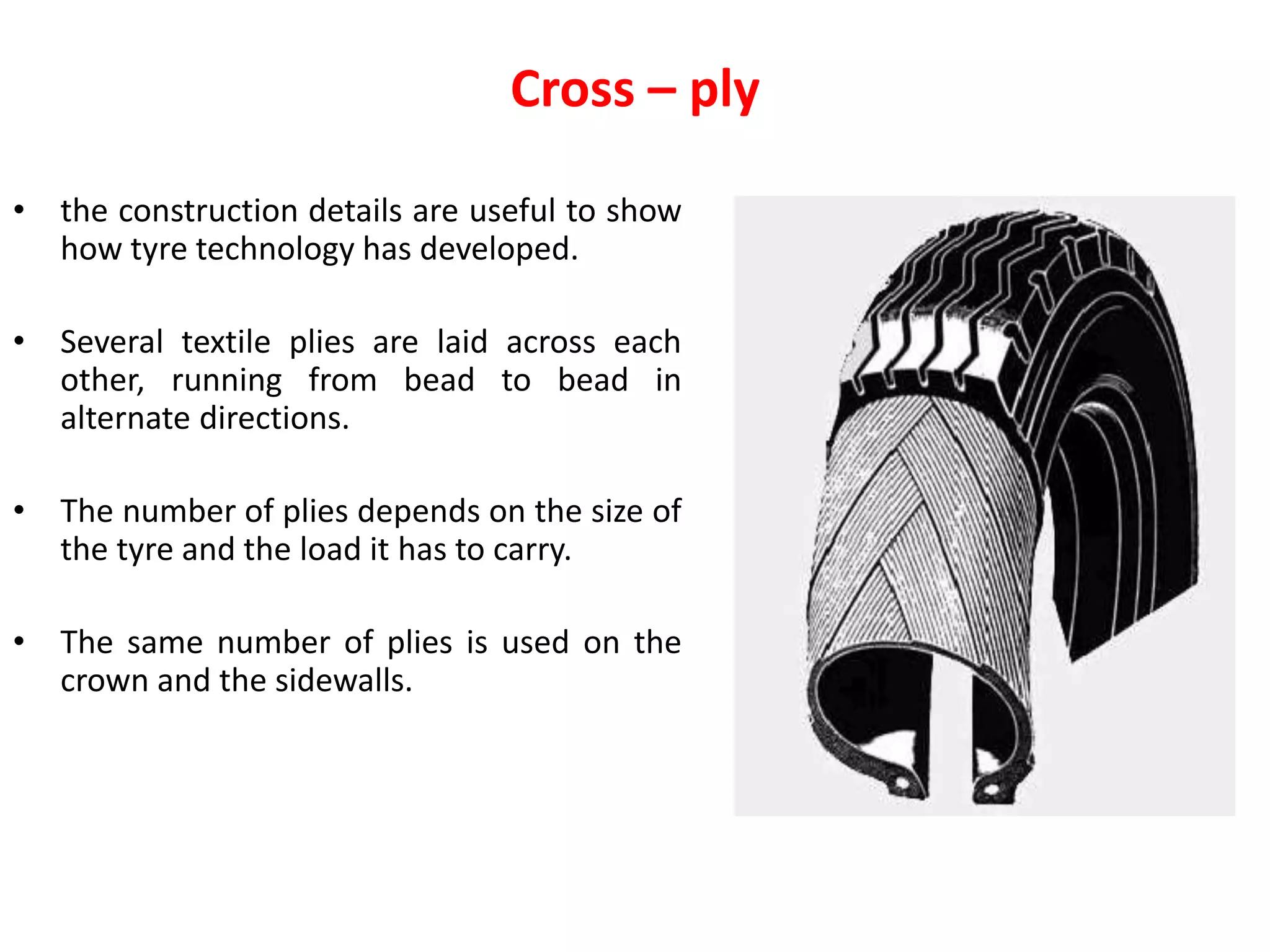

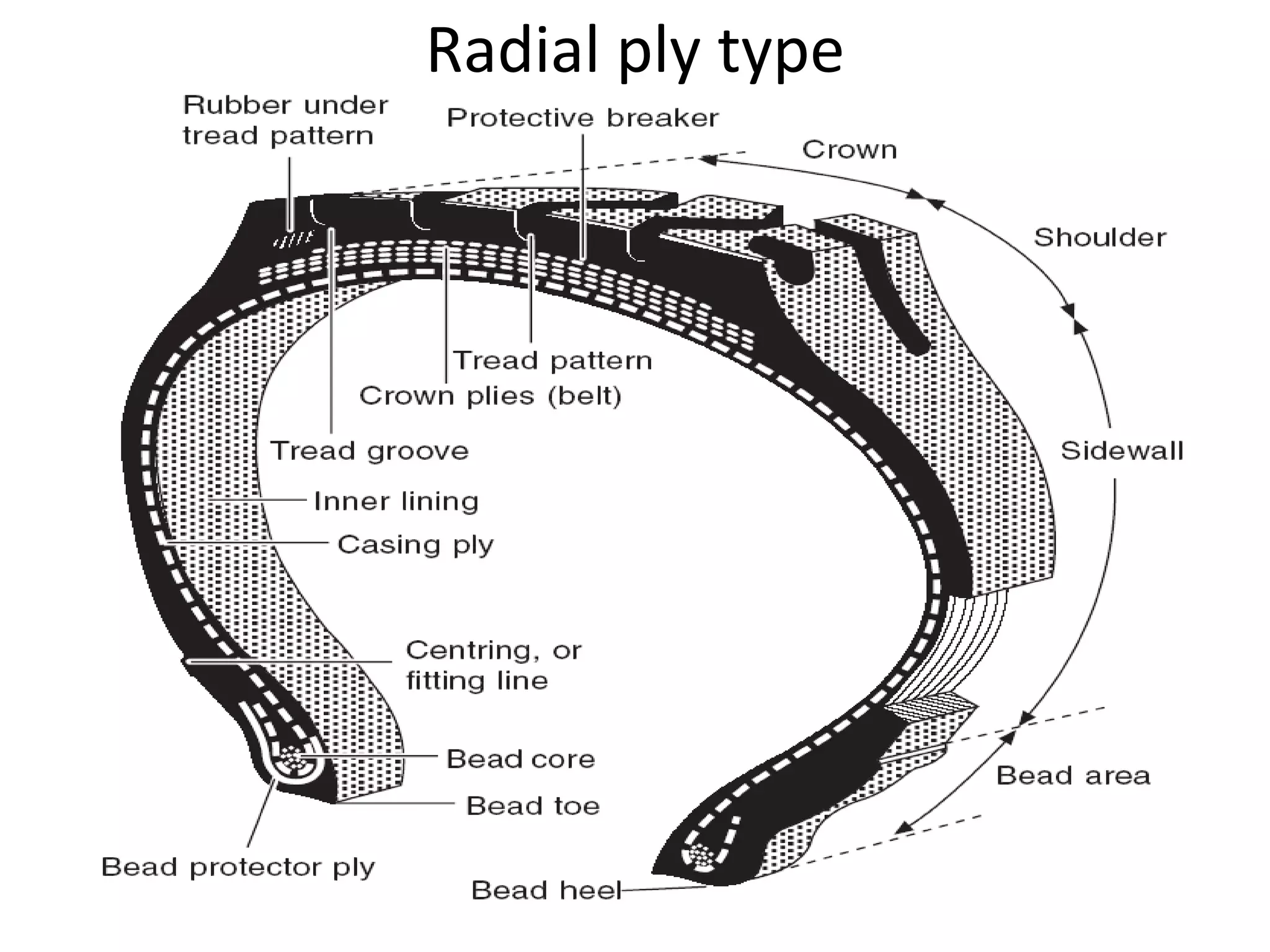

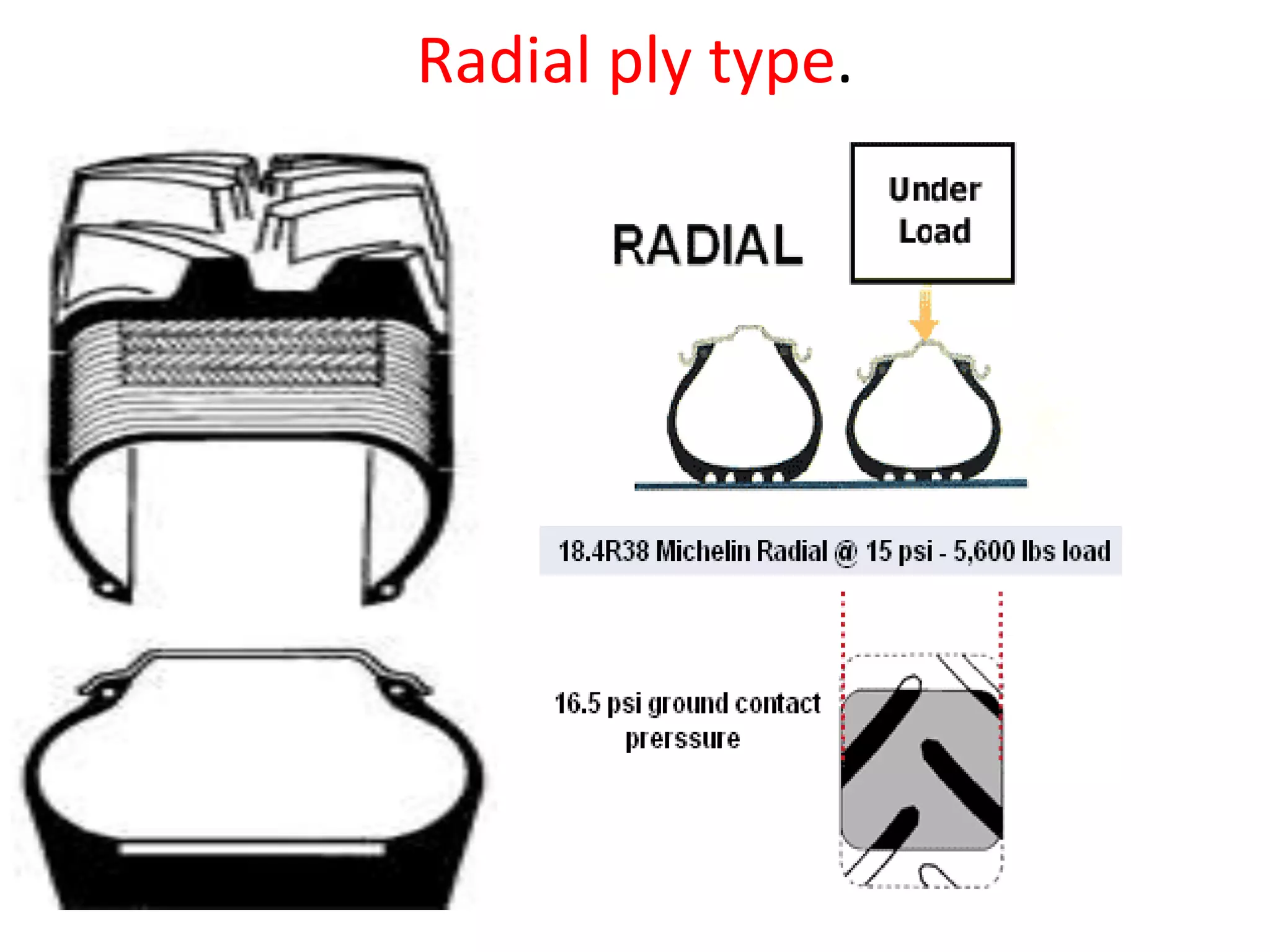

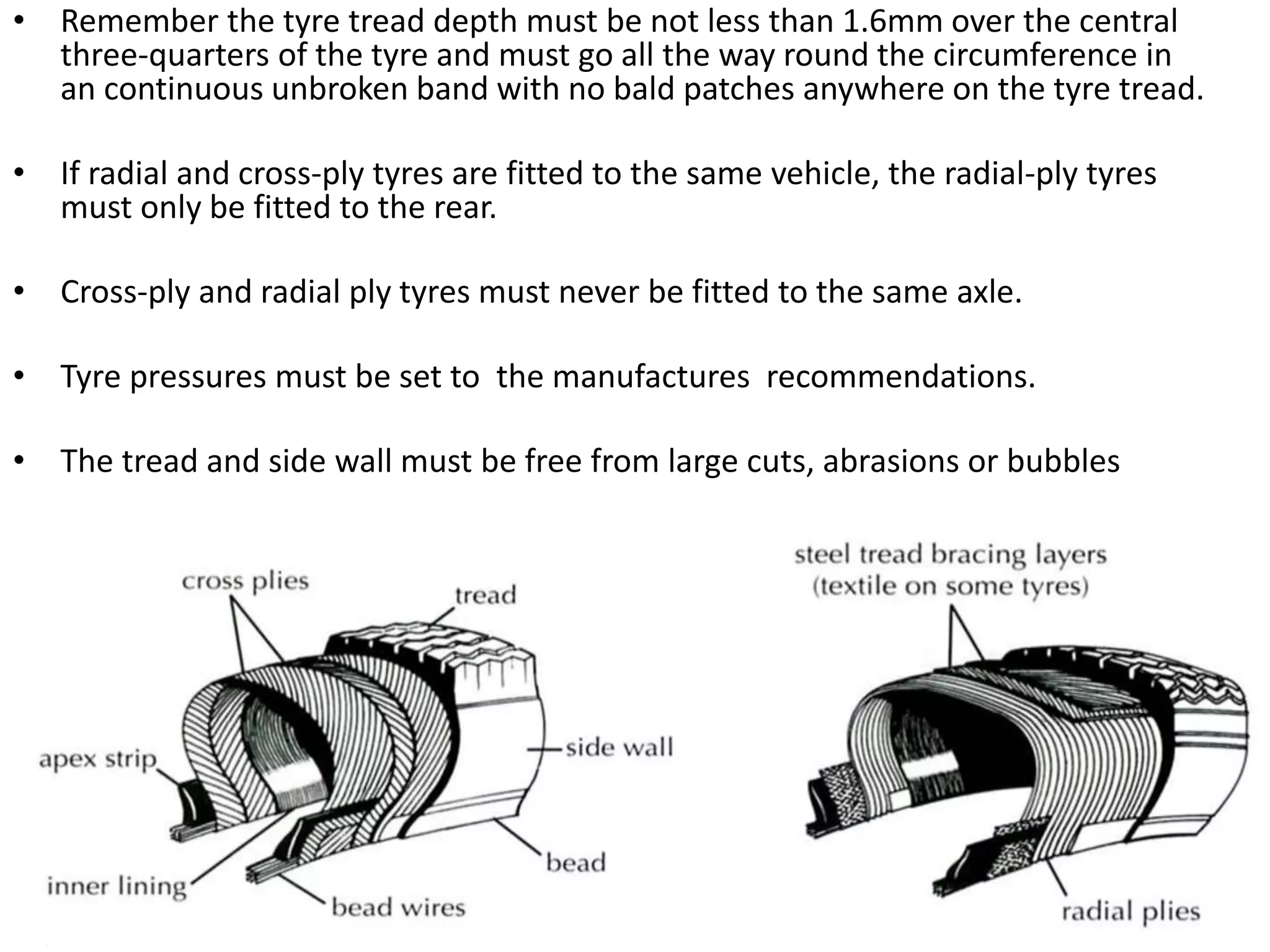

The document also describes different tire constructions - cross-ply/bias ply tires which have fabric plies laid across each other at alternating angles, radial ply tires which have fabric arcs from bead to bead at 90 degree angles, and belted bias ply tires which have belt plies reinforced with wire. Radial ply tires provide benefits like better shock absorption and fuel efficiency compared to cross-ply tires.