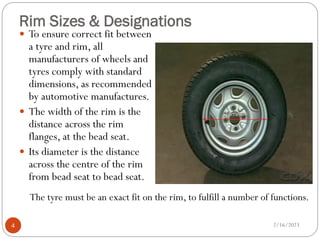

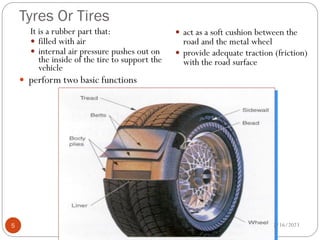

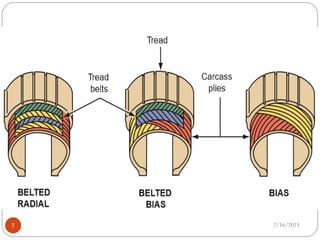

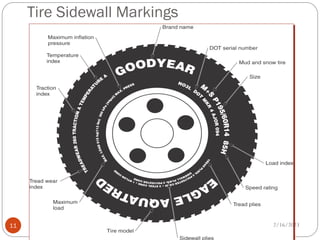

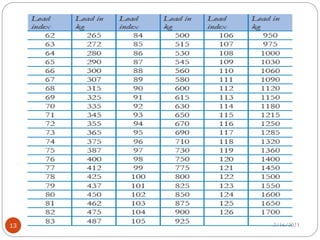

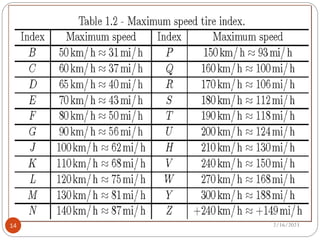

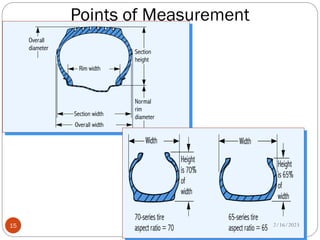

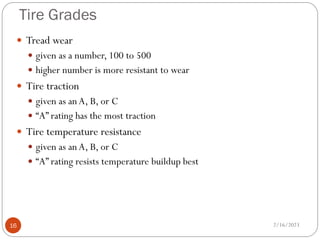

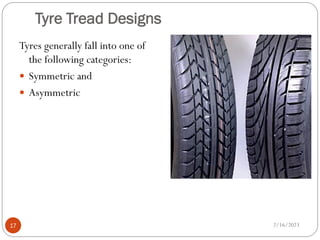

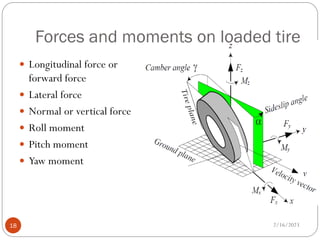

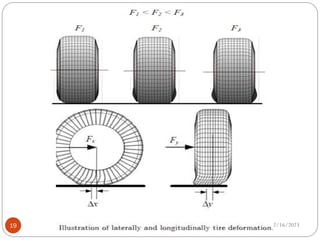

This document explains the construction and function of pneumatic tires and wheels, emphasizing the importance of rim strength, compatibility between tires and rims, and various tire types, particularly radial tires. It details the benefits of radial tires over bias tires, such as improved fuel economy and longer life, as well as materials used in tire manufacturing and necessary specifications like maximum load rating and inflation pressure. Additionally, the document covers tire grades, tread designs, and forces acting on loaded tires.