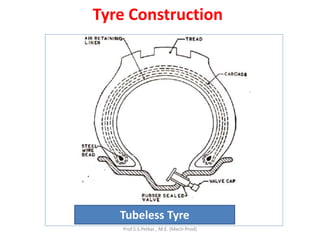

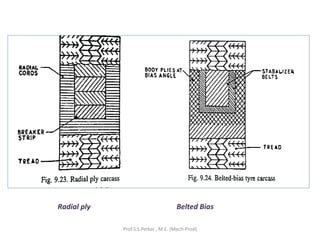

The document provides an overview of wheels and tyres, detailing various types such as pressed steel disc wheels, wire wheels, and light alloy wheels, along with their advantages, applications, and construction methods. It discusses the importance of wheel balancing and tyre construction, including materials, tread patterns, and factors affecting tyre performance. Additionally, it covers tyre wear types, retreading processes, and the selection of tyres for different applications.