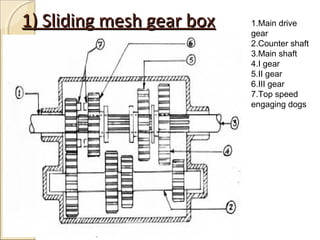

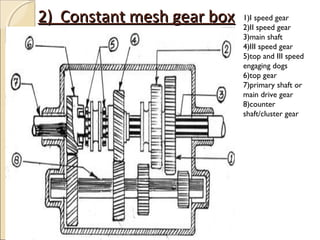

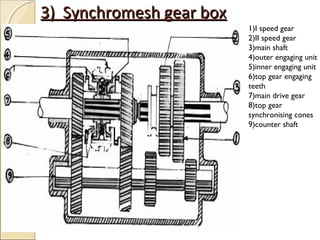

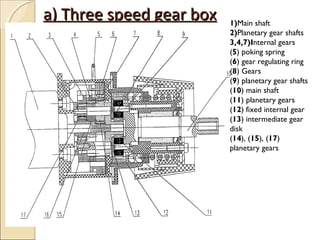

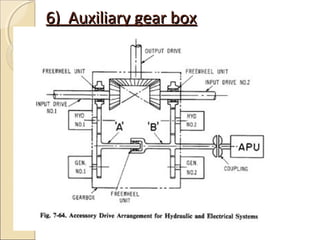

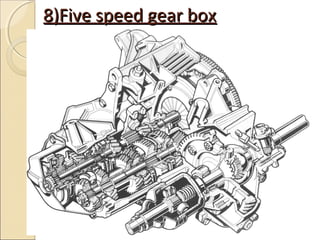

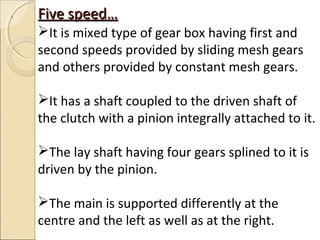

This document discusses different types of gear boxes used in vehicles. It describes 8 types: 1) Sliding mesh gear box, 2) Constant mesh gear box, 3) Synchromesh gear box, 4) Preselective gear box, 5) Epicyclical gear box, 6) Auxiliary gear box, 7) Freewheel drive, and 8) Five speed gear box. For each type, it provides details on their components, operation, and advantages over other types. The overall purpose is to explain the various mechanisms used in gear boxes to maintain engine speed under different load and speed conditions.