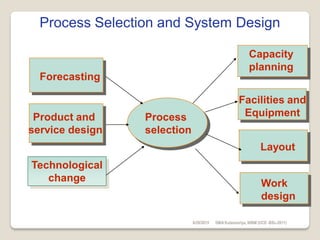

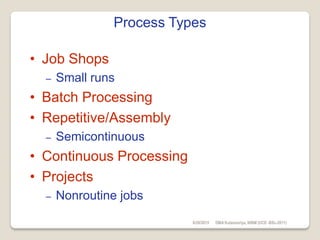

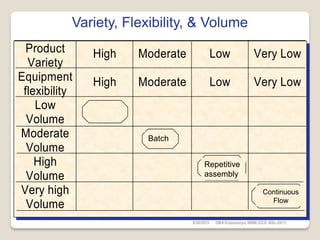

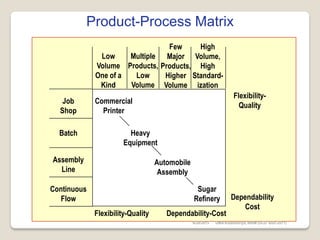

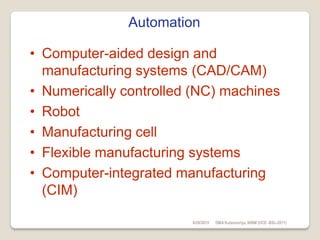

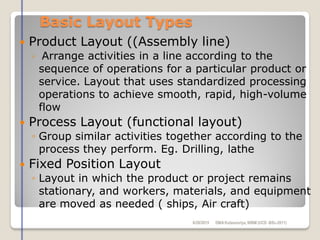

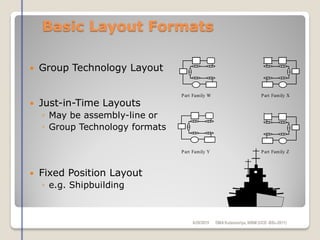

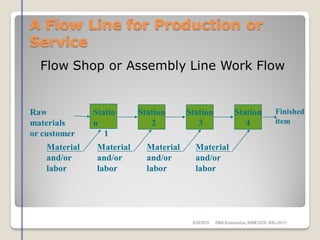

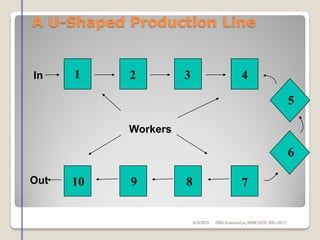

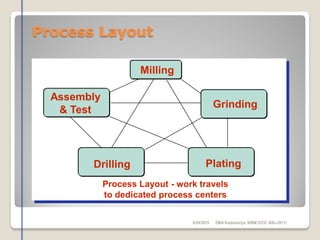

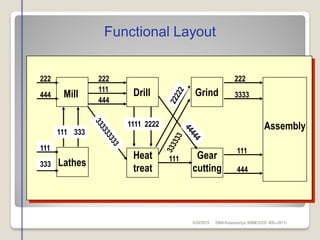

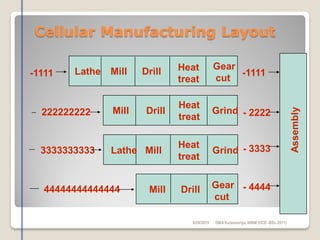

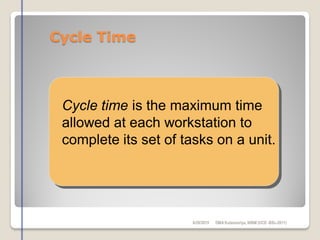

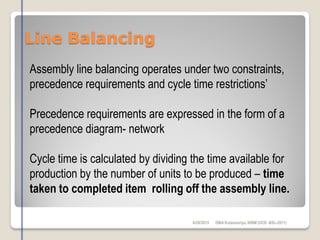

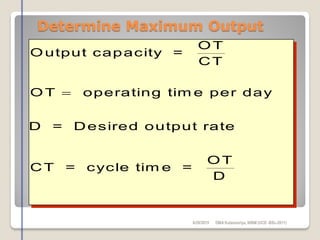

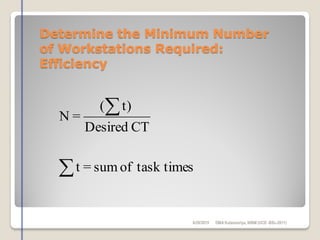

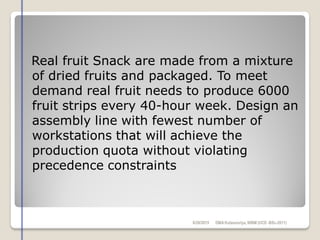

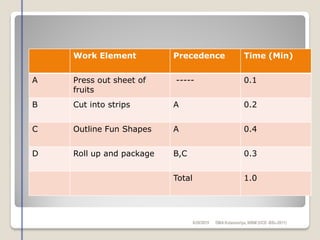

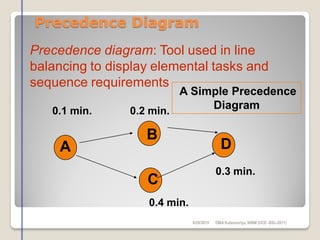

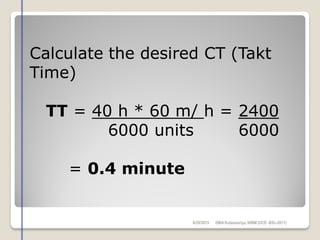

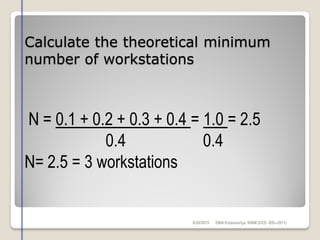

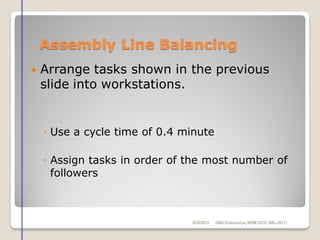

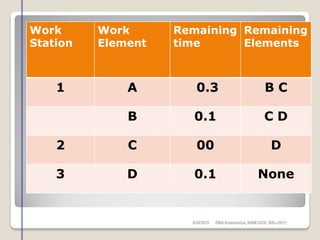

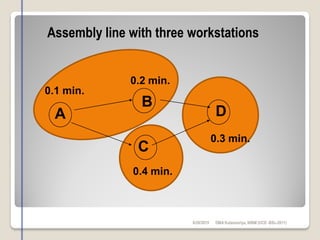

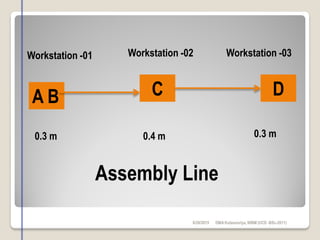

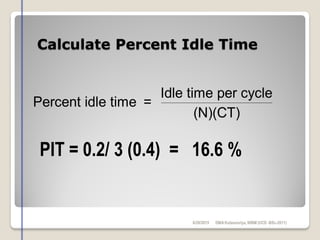

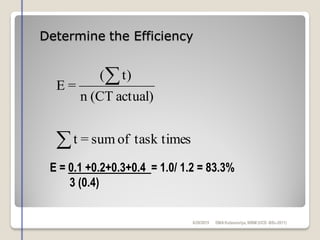

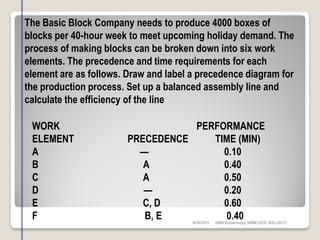

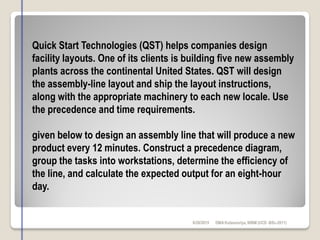

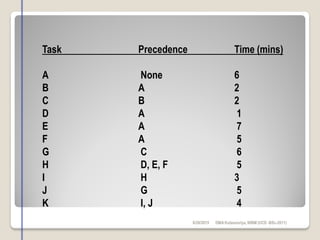

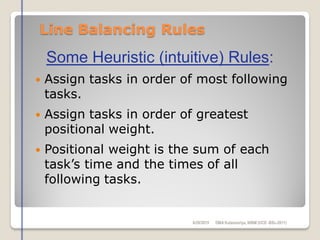

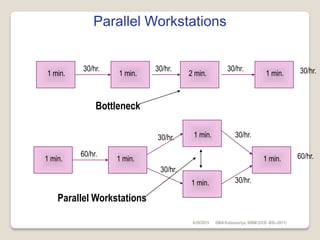

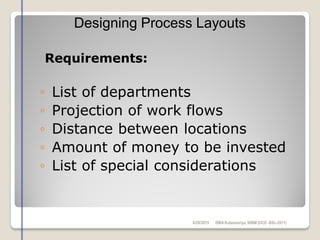

The document discusses process design and facility layout. It covers topics like process selection, automation, basic layout types including product, process and fixed-position layouts. It also discusses cellular layouts, line balancing to determine the minimum number of workstations, and calculates efficiency. An example of designing a fruit snack assembly line is provided to illustrate the concepts.