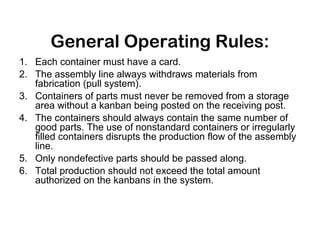

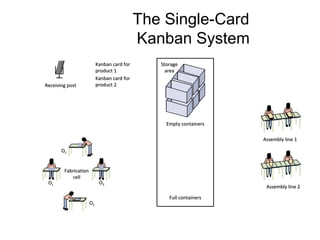

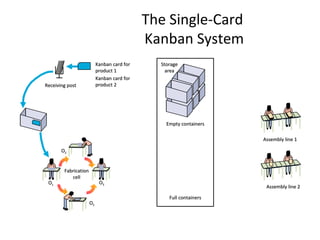

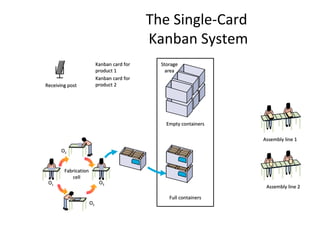

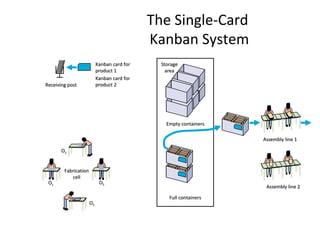

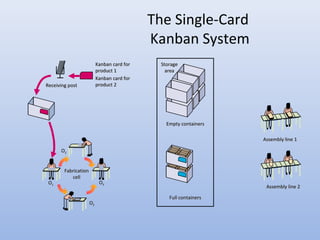

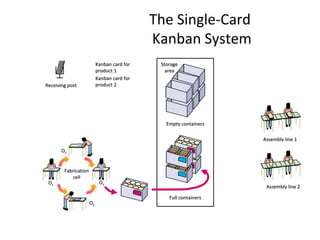

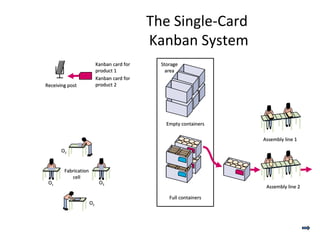

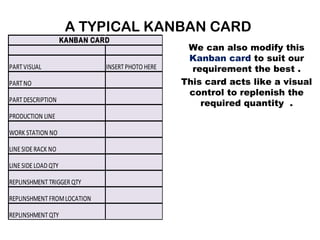

Kanban systems use a pull method of workflow where production is triggered by customer demand rather than being prepared in advance. Kanban refers to cards that control material flow through each stage of production by signaling when more items need to be fabricated. The cards ensure a smooth flow and limit excess work in progress inventory. Each container of parts has a card and can only be removed from storage when a card is posted, following the pull system approach.