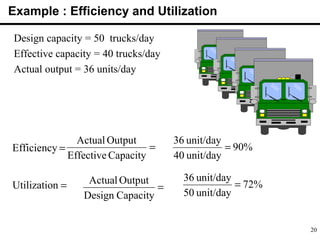

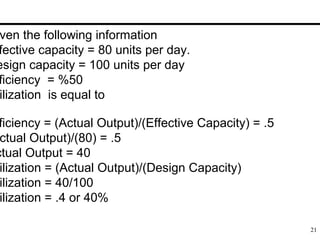

Here are the calculations to find utilization given the information provided:

Effective capacity = 80 units per day

Design capacity = 100 units per day

Efficiency = 50%

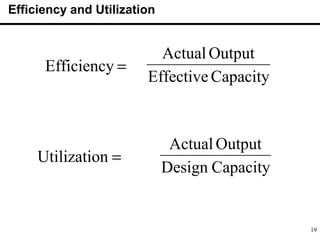

Efficiency = (Actual Output)/(Effective Capacity) = .5

(Actual Output)/(80) = .5

Actual Output = 40

Utilization = (Actual Output)/(Design Capacity)

Utilization = 40/100

Utilization = .4 or 40%

Therefore, given the information provided, the utilization is 40%.