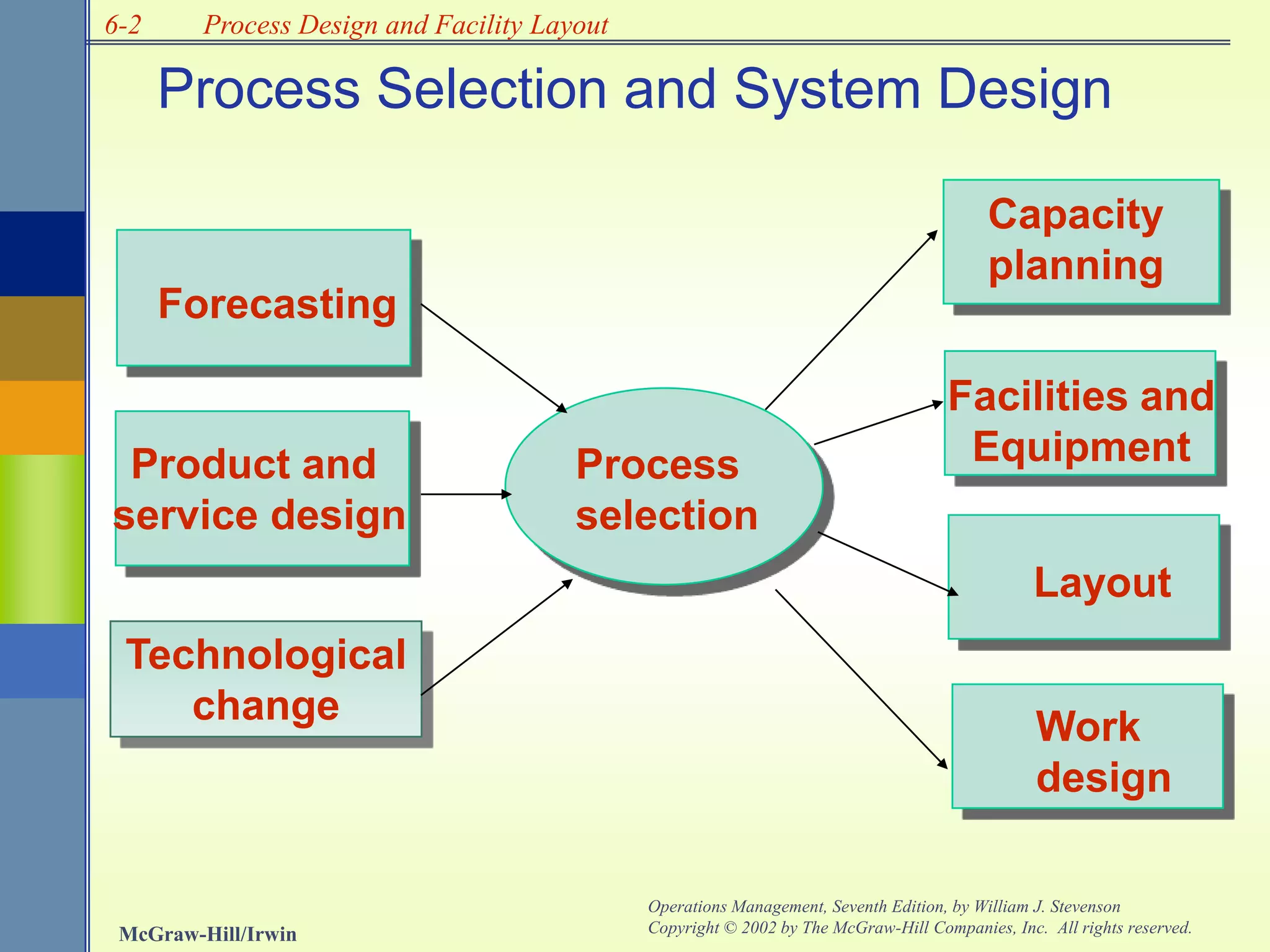

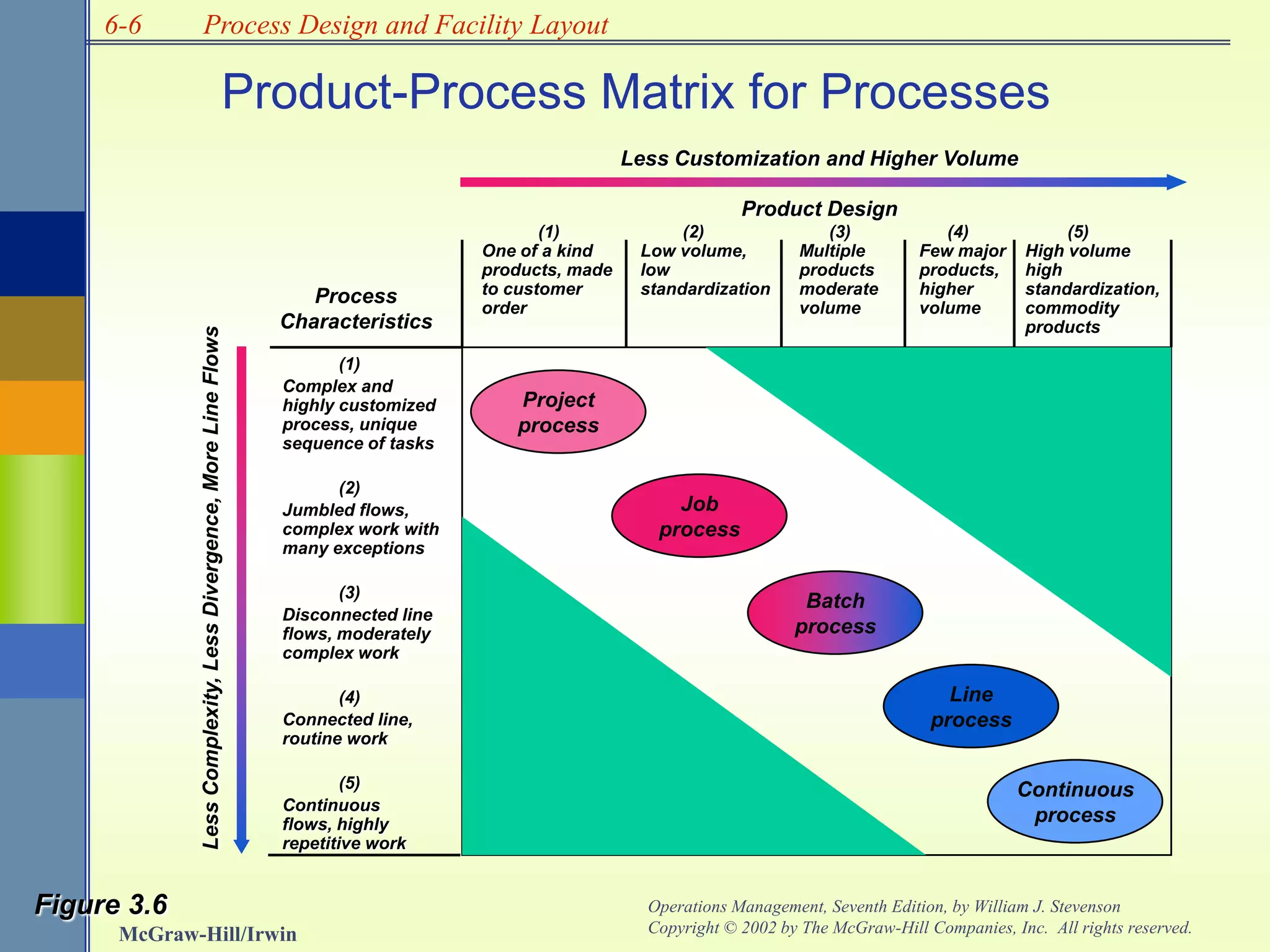

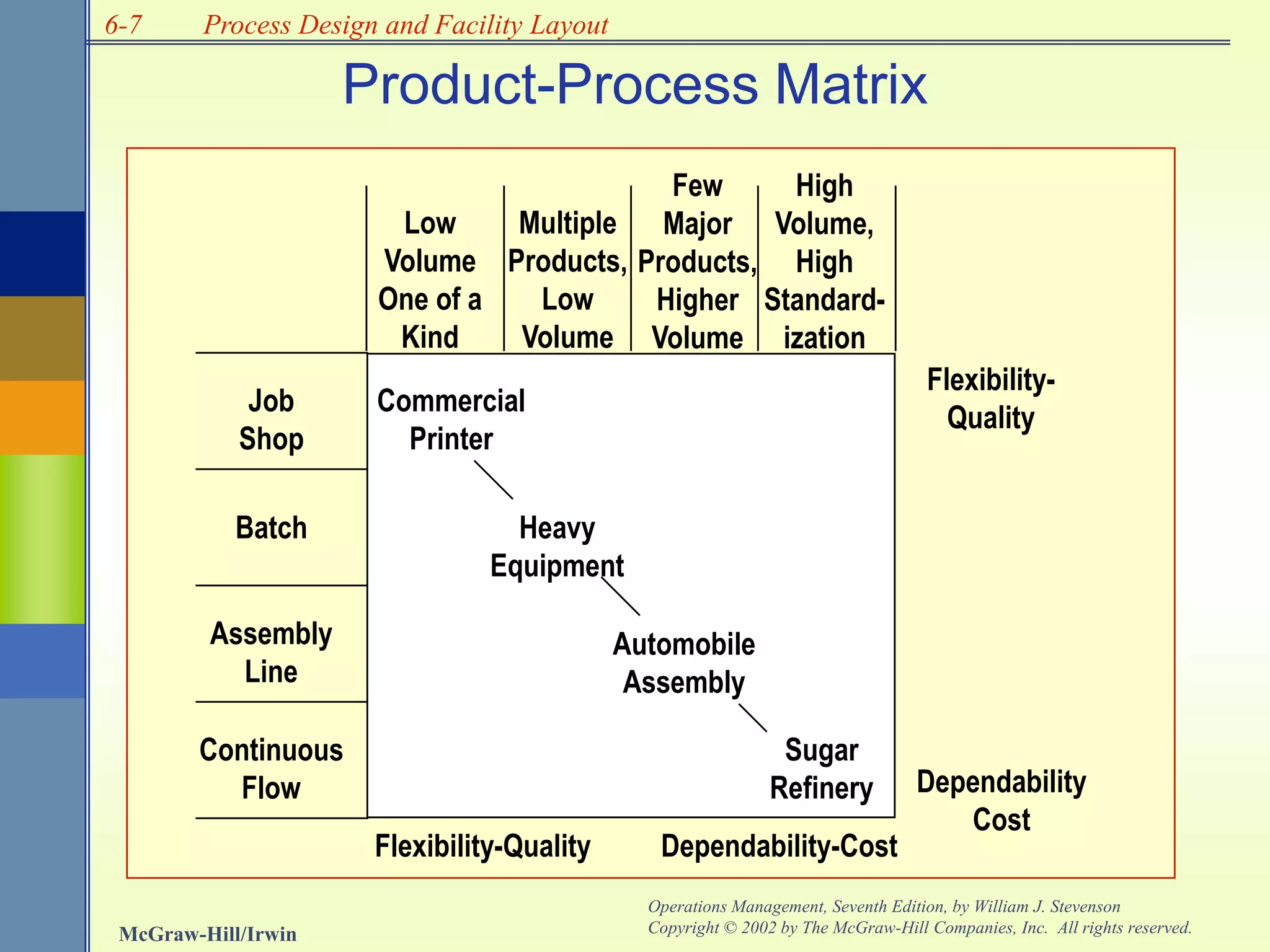

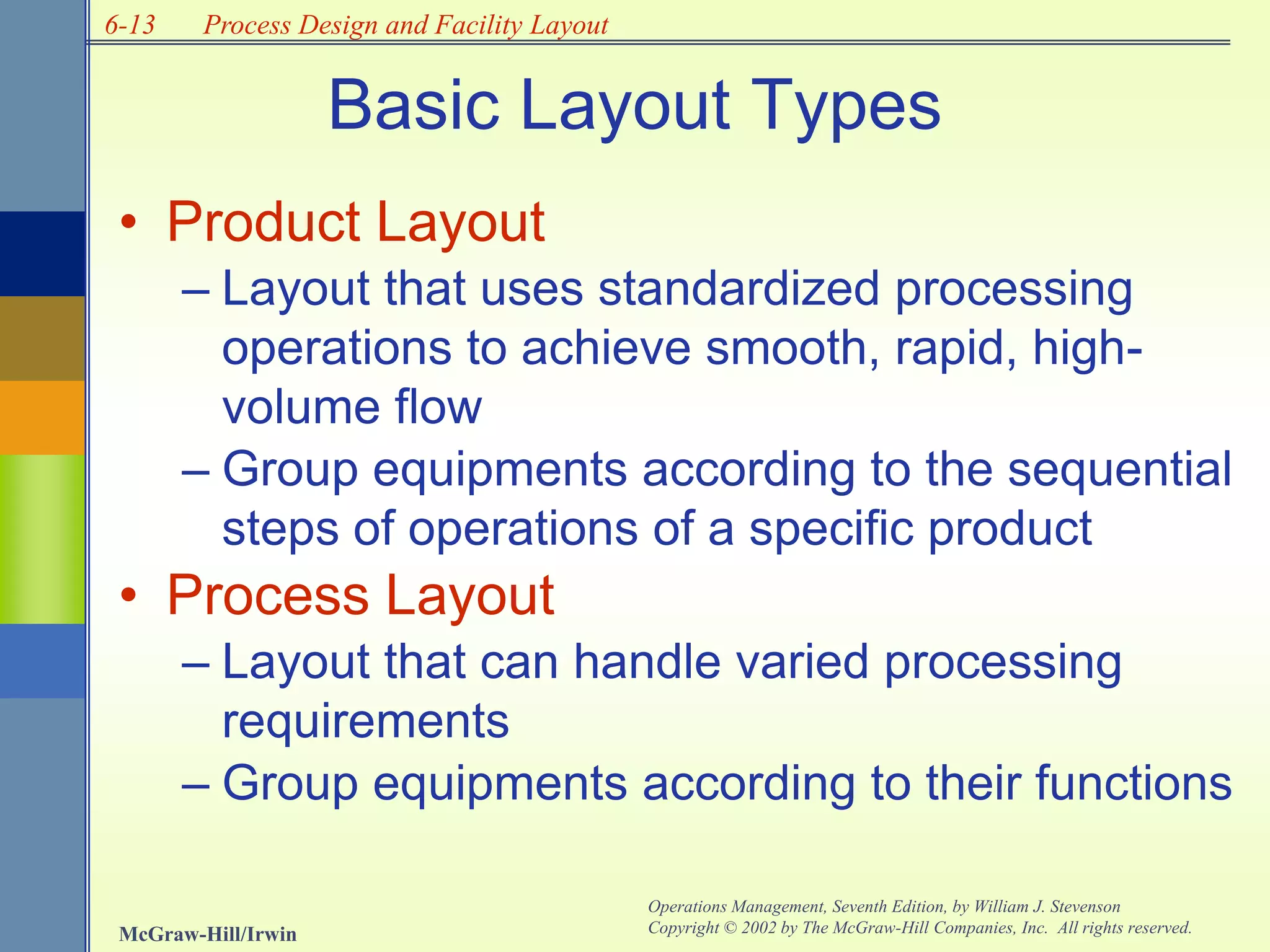

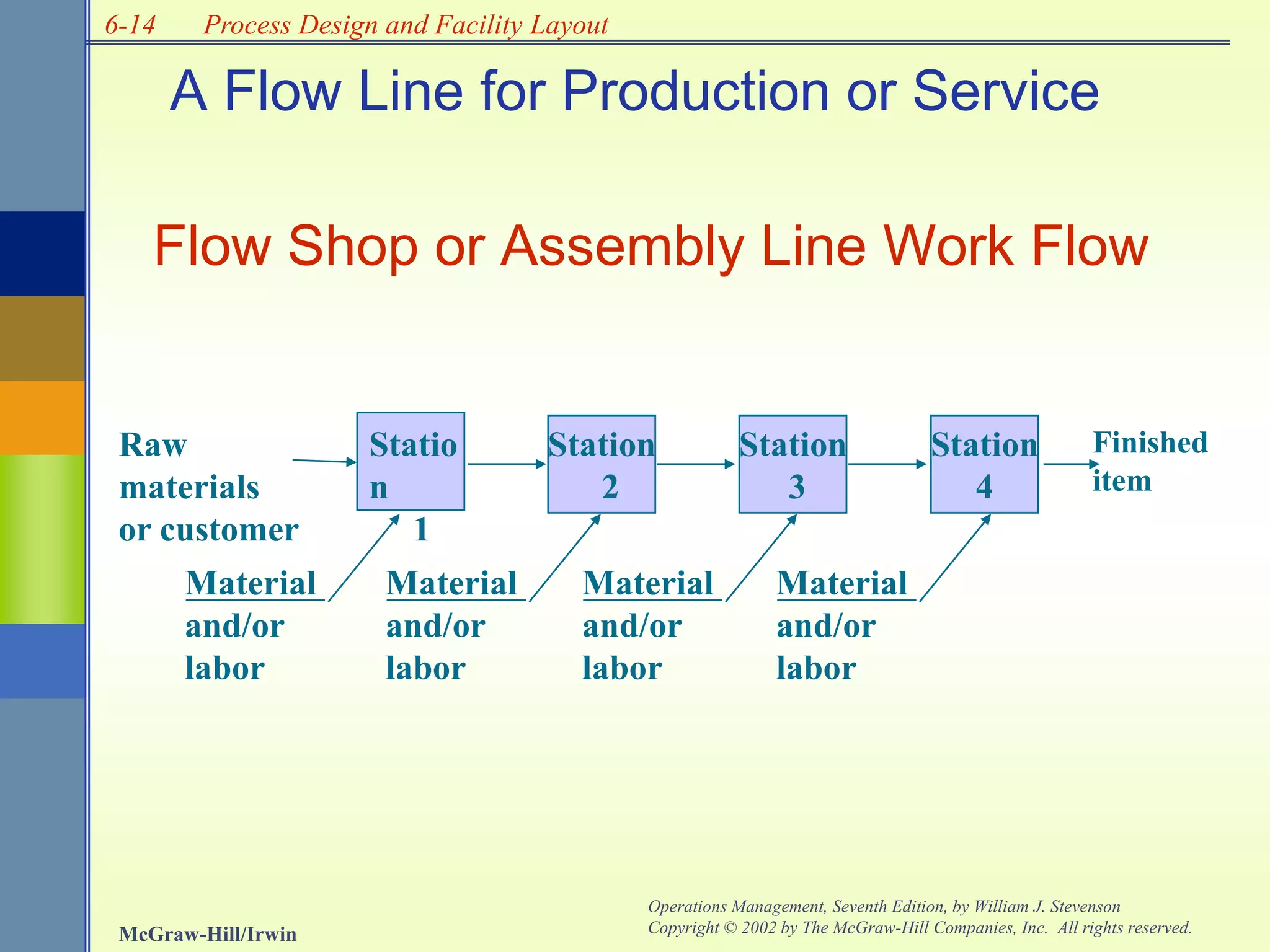

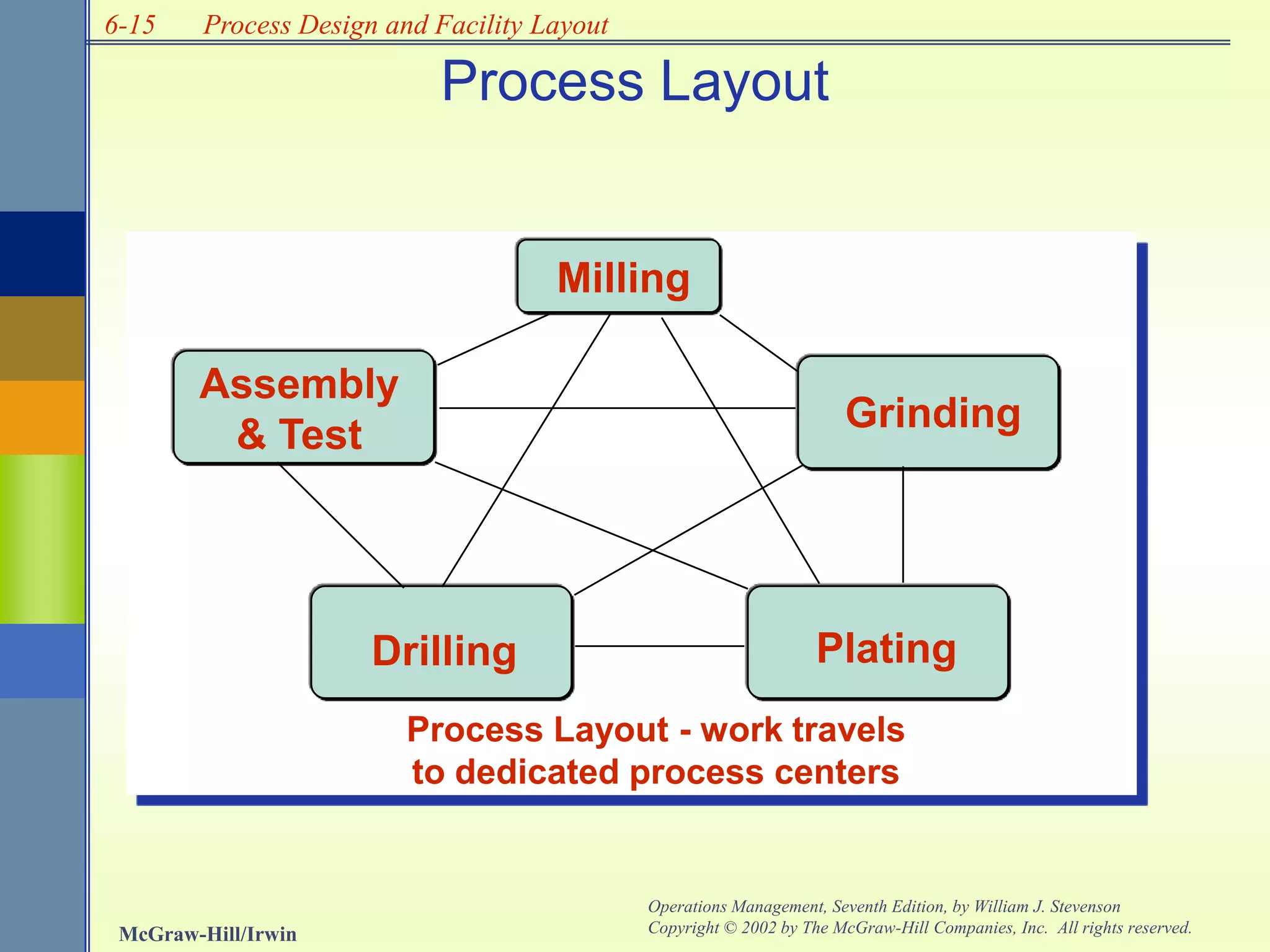

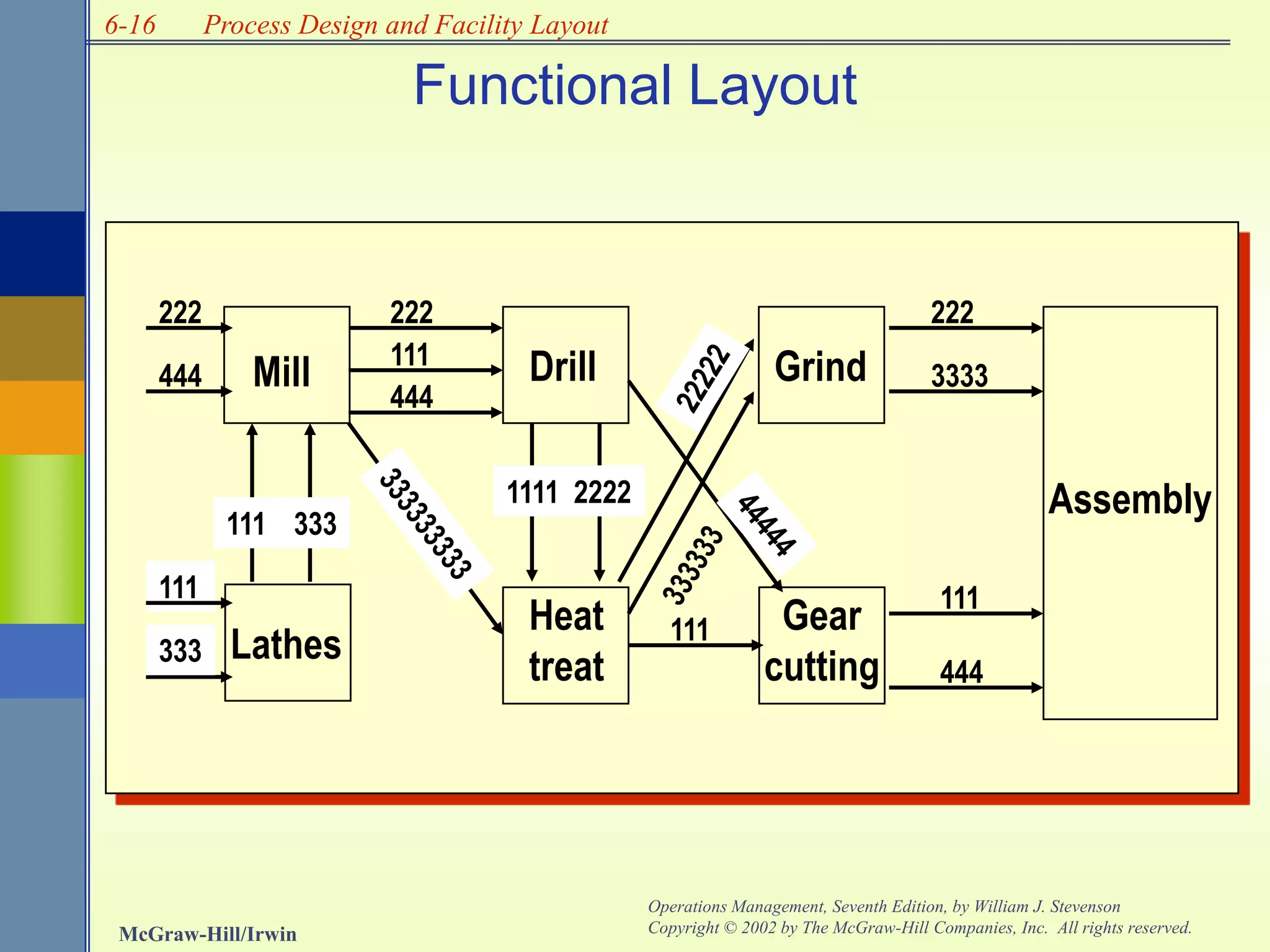

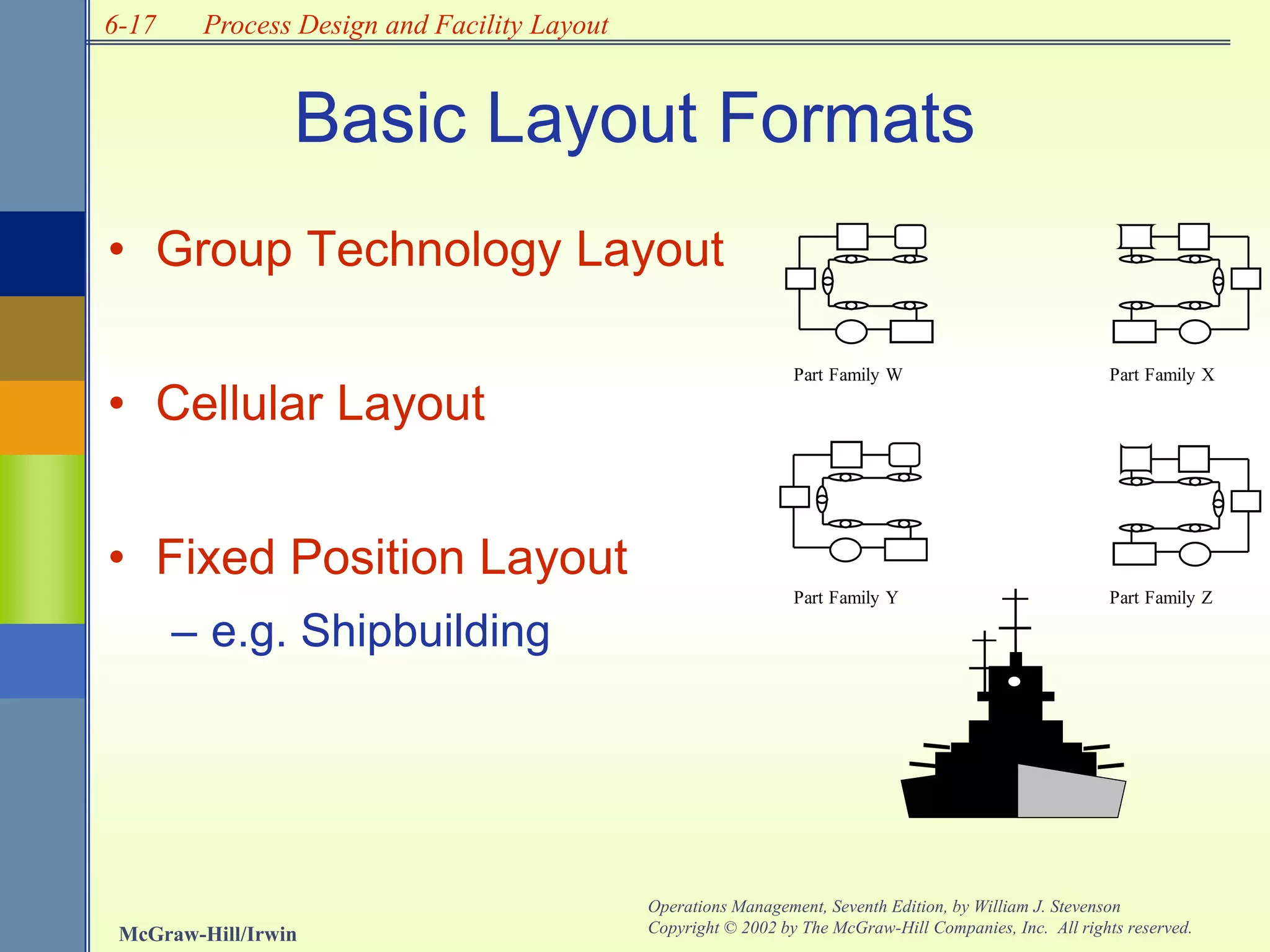

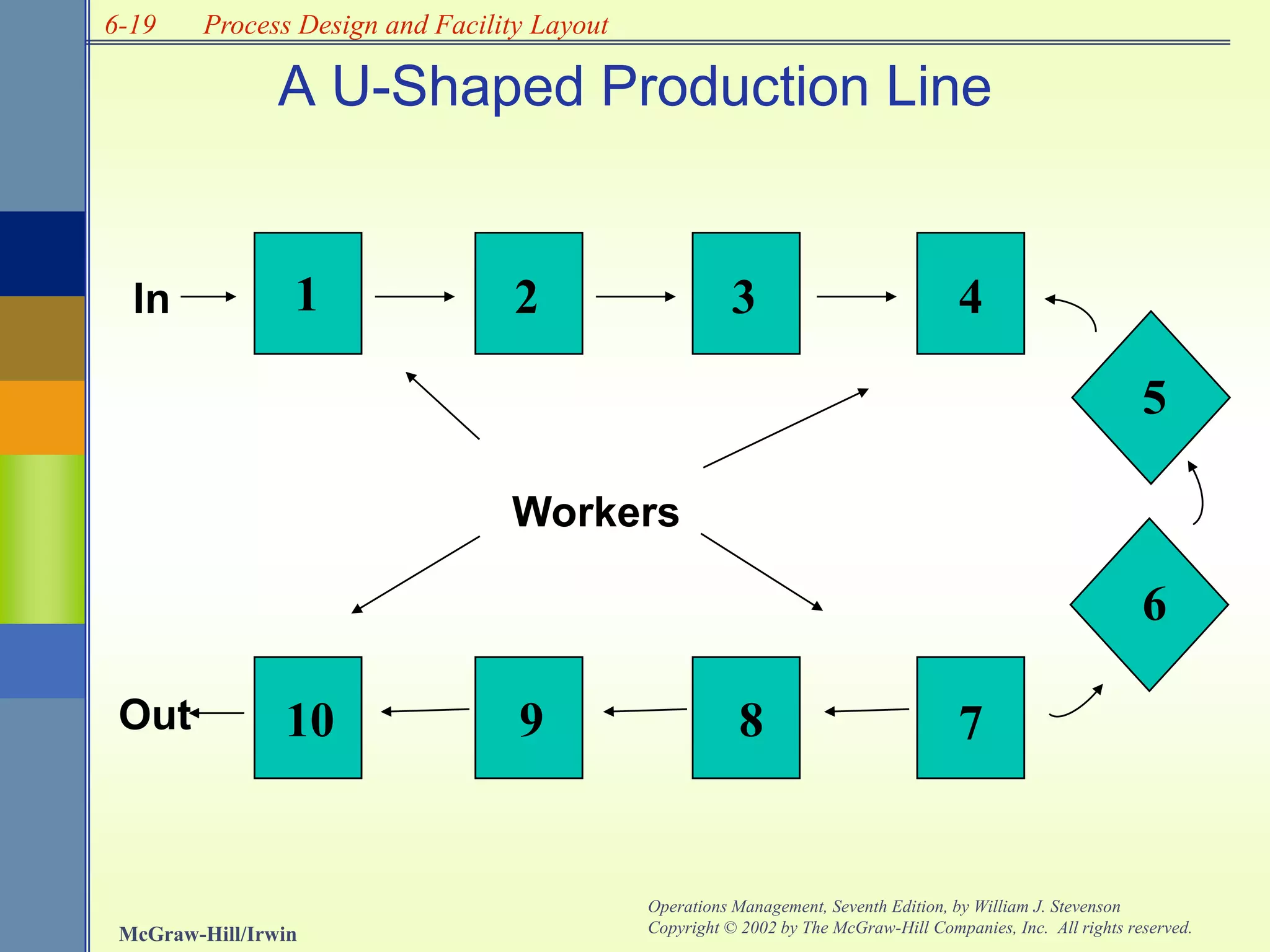

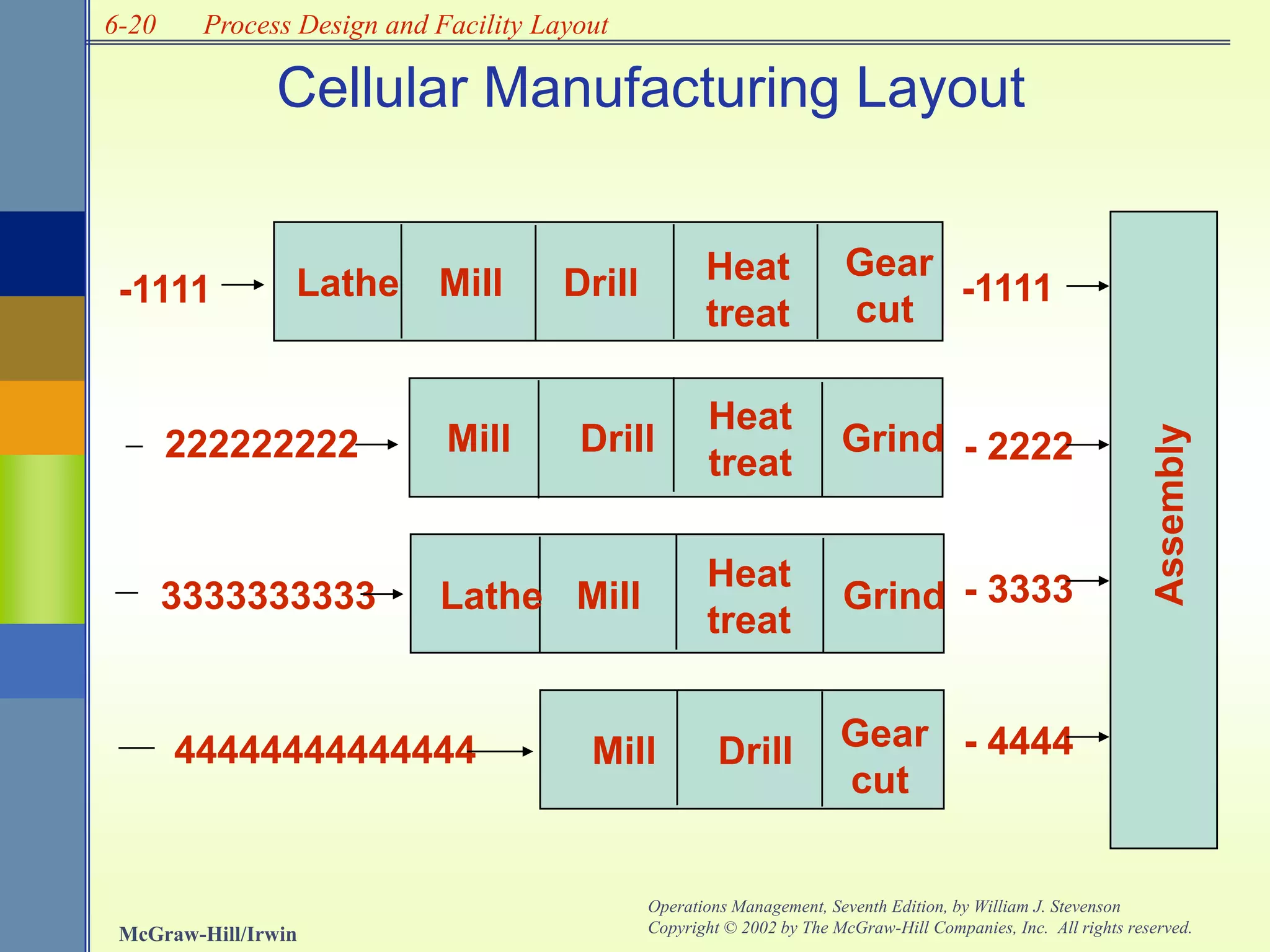

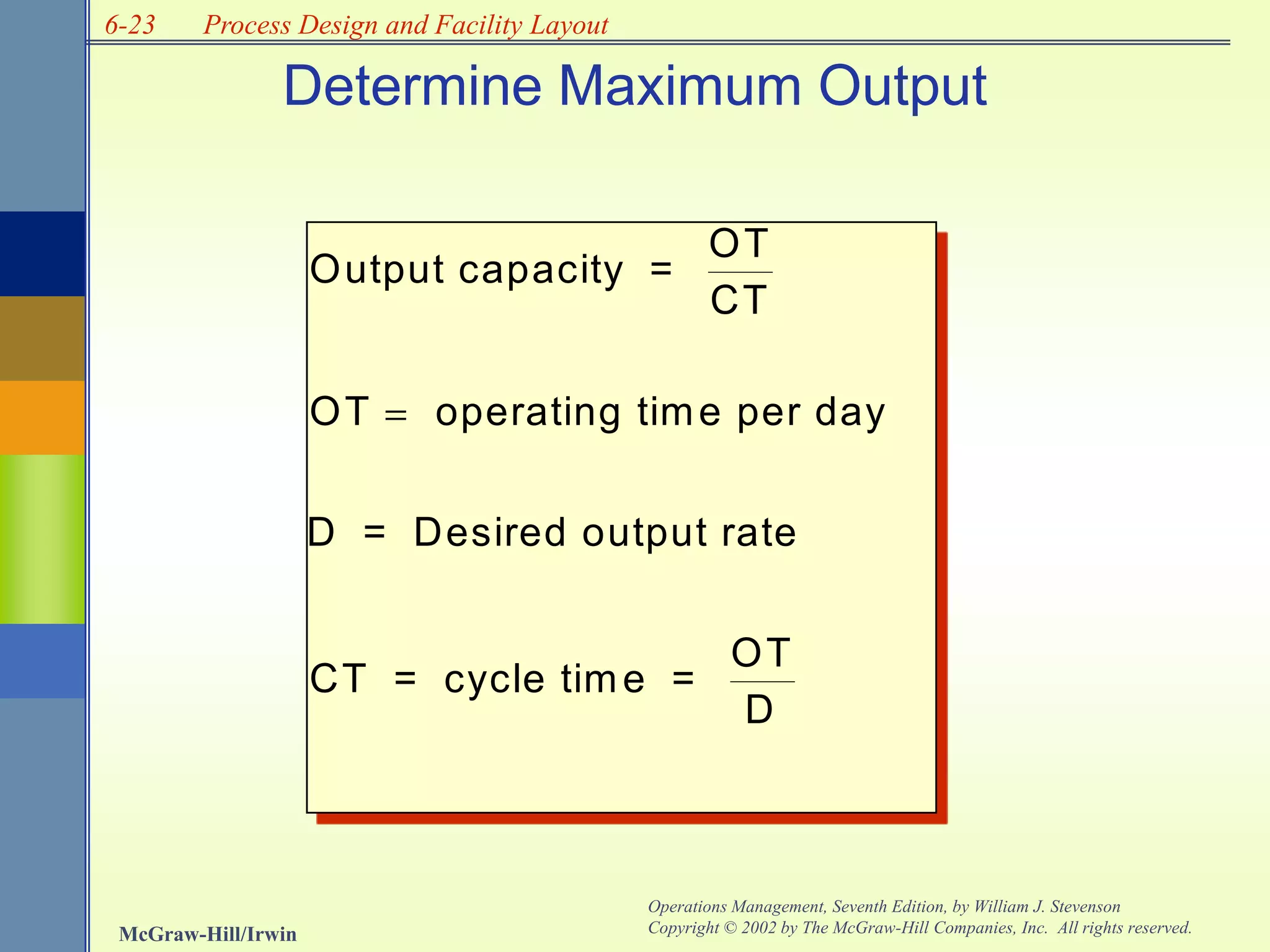

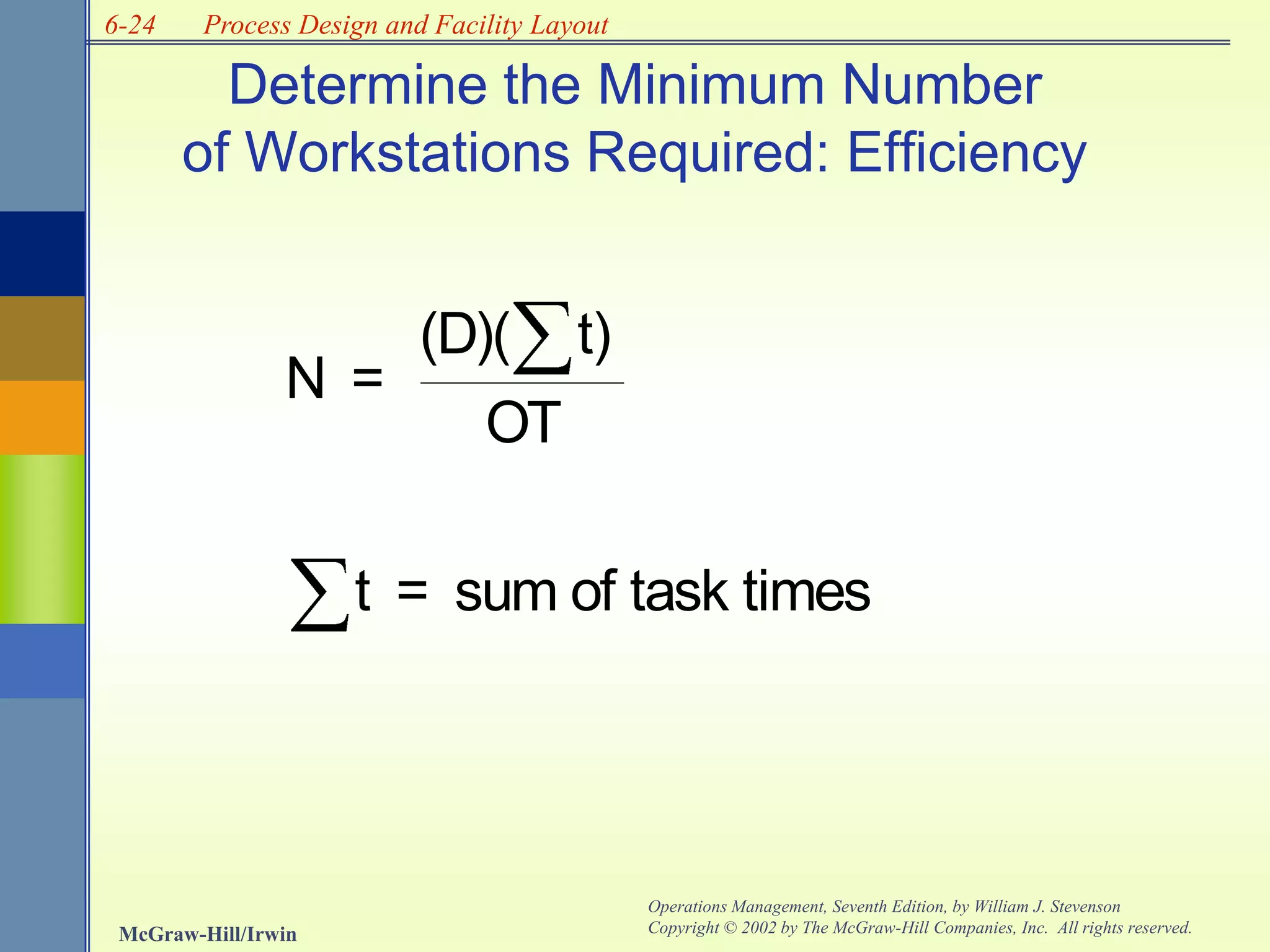

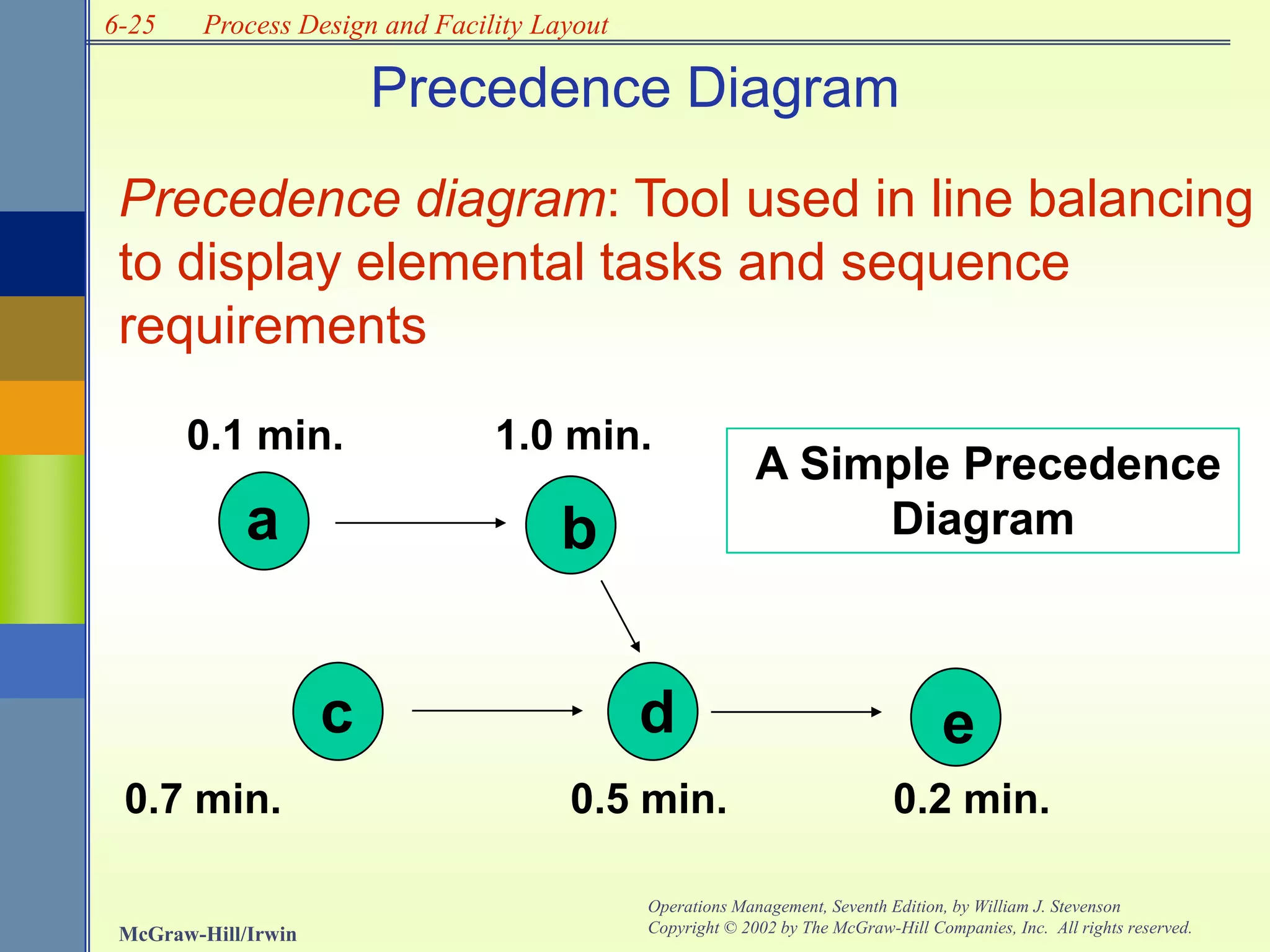

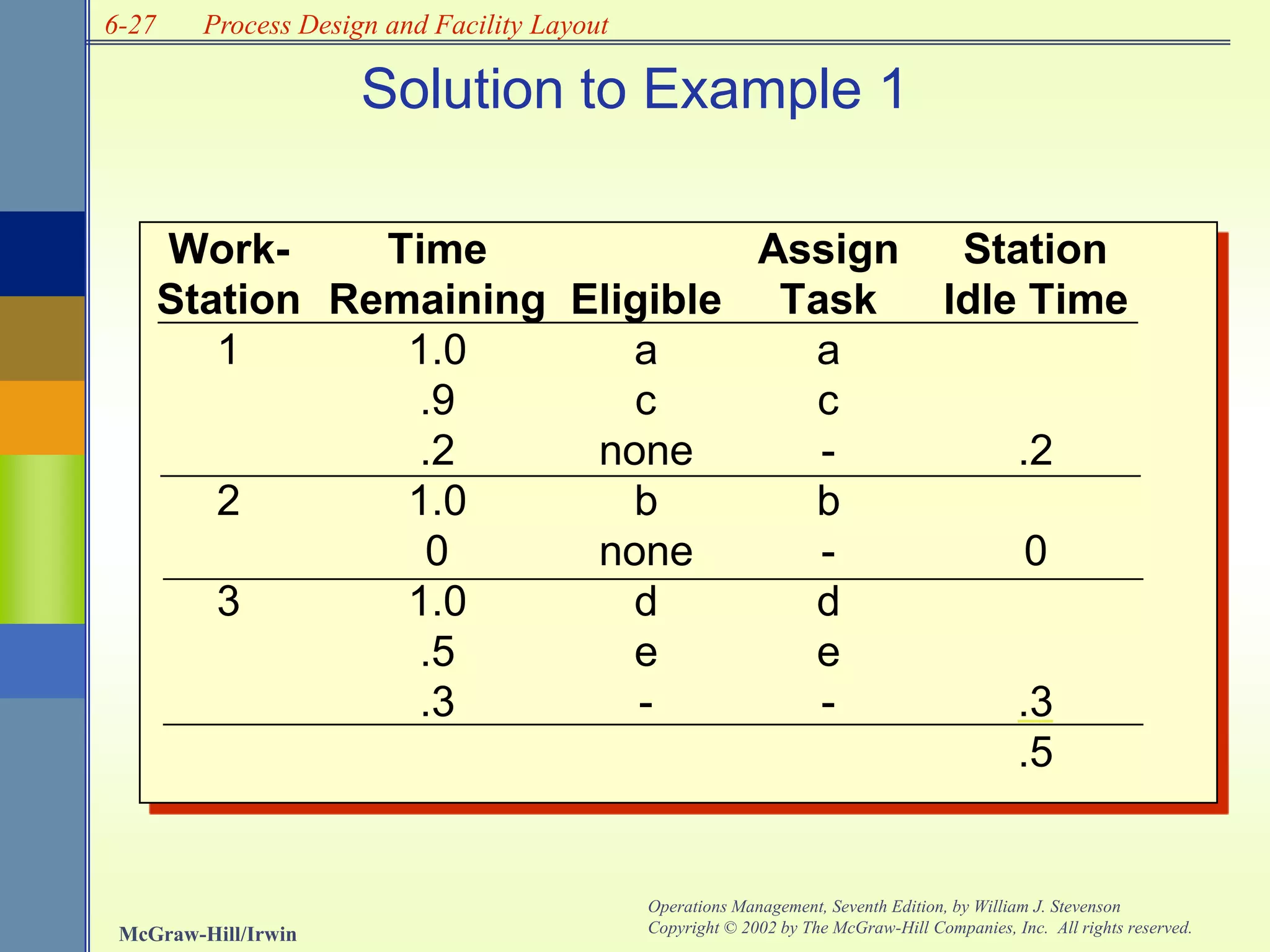

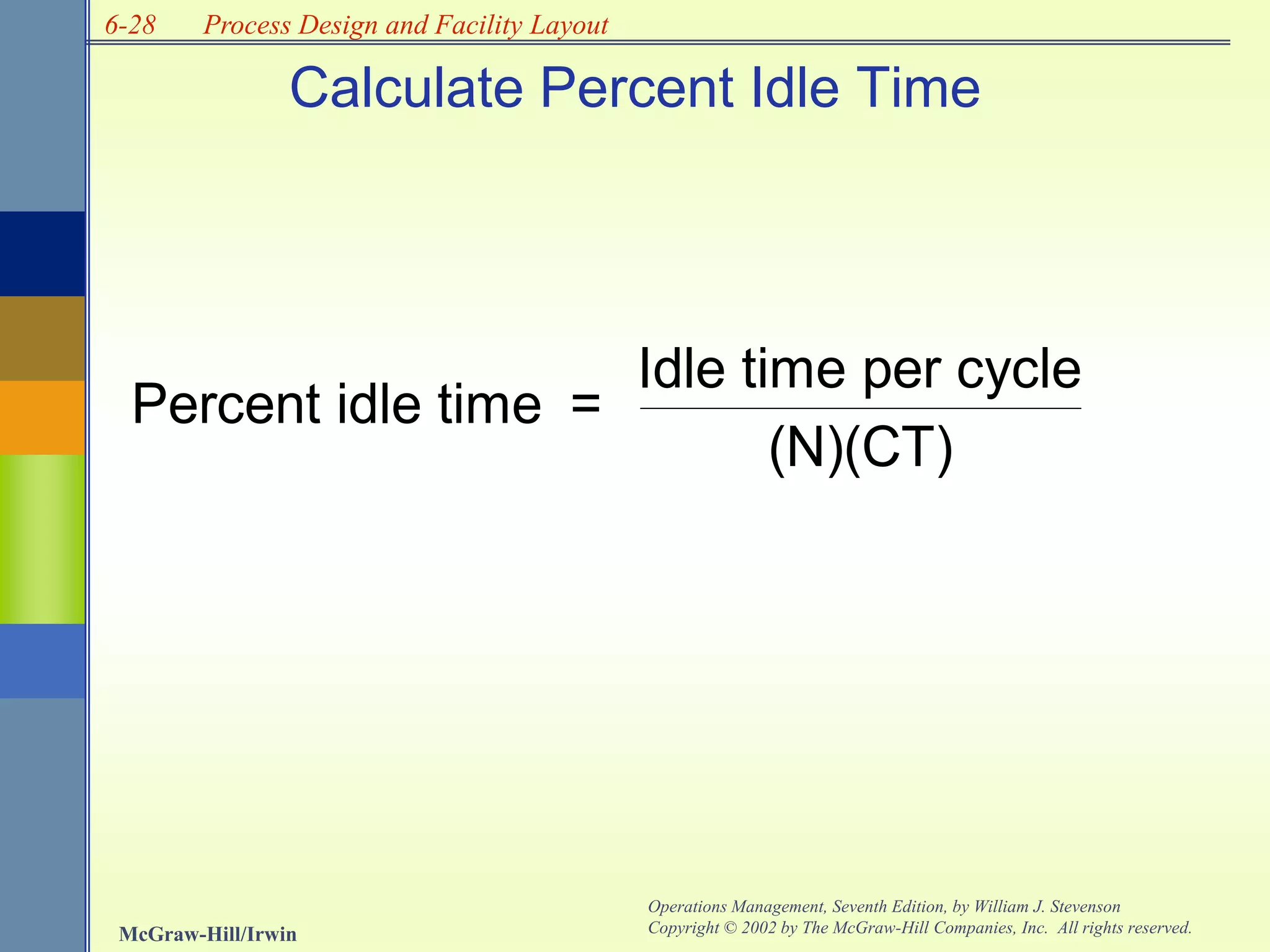

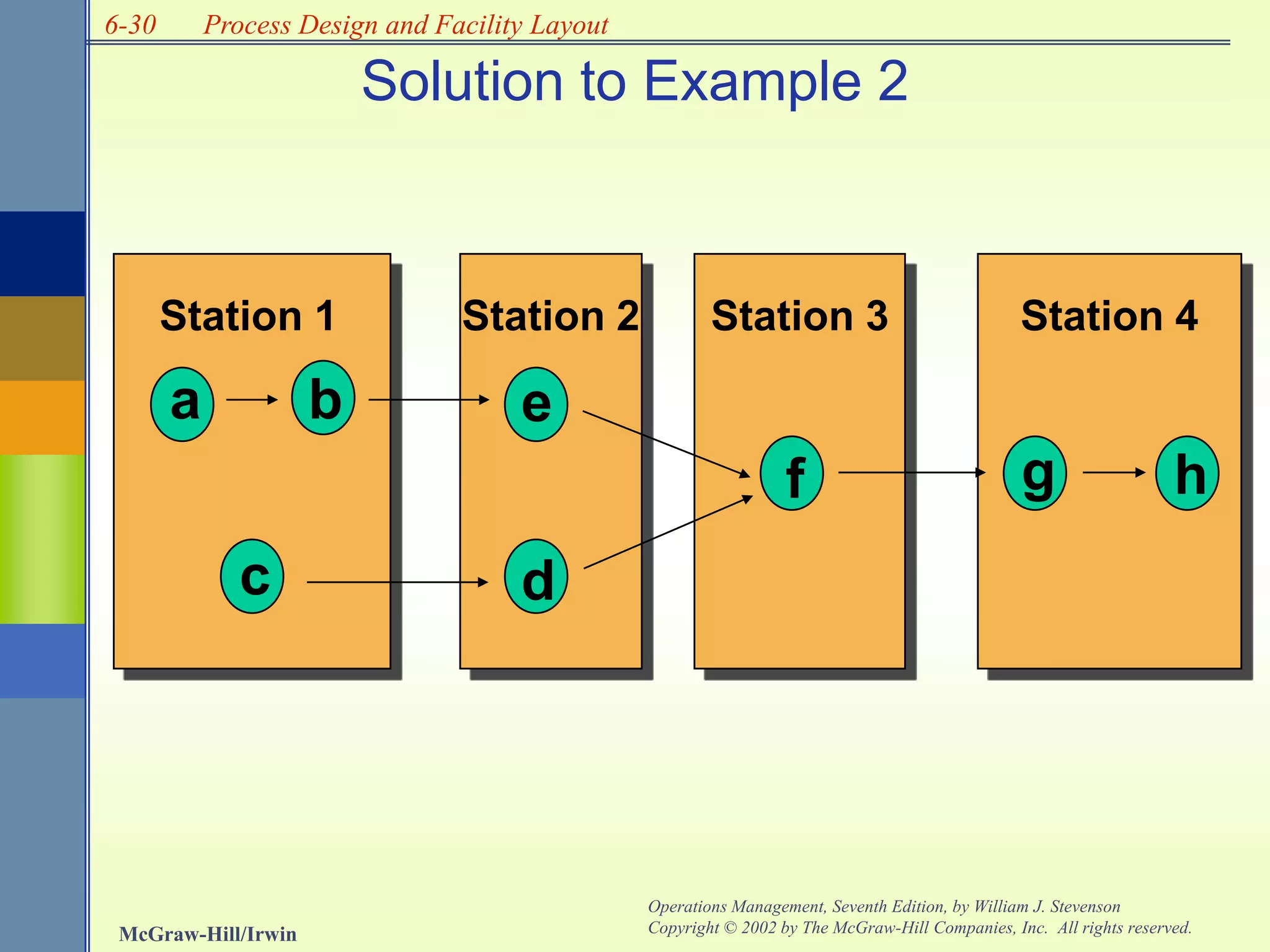

The document discusses process design and facility layout. It covers types of processes like projects, job shops, batch processing, repetitive/assembly and continuous processing. The key factors in selecting a process are variety, flexibility, volume and the tradeoff between them. Layout types include product layouts that group equipment by product steps, process layouts that group by function, and combination layouts. The document provides examples of line balancing to optimize workstation times and productivity.