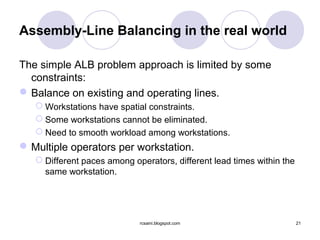

1. Assembly-line balancing is the process of assigning tasks to workstations along an assembly line to maximize efficiency.

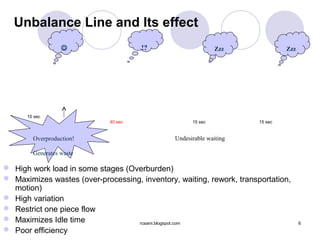

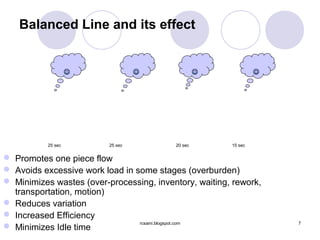

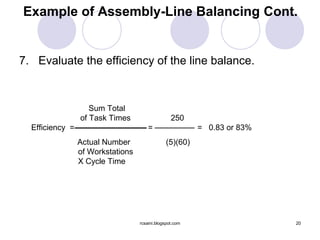

2. It aims to balance the workload across stations so that no station is a bottleneck and idle time is minimized.

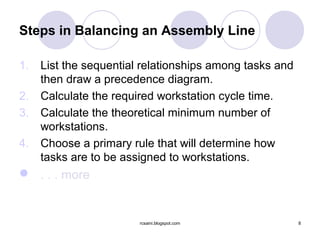

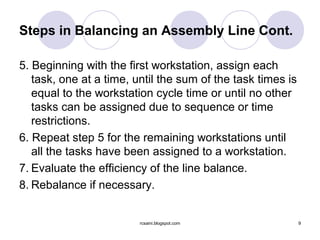

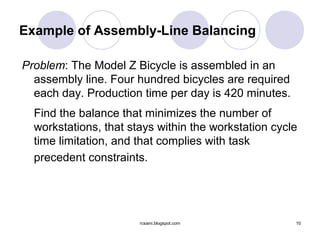

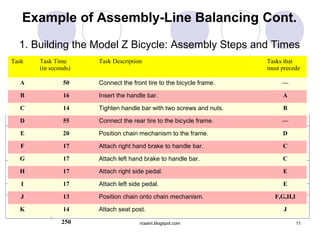

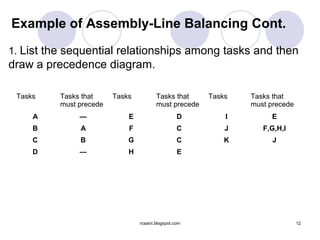

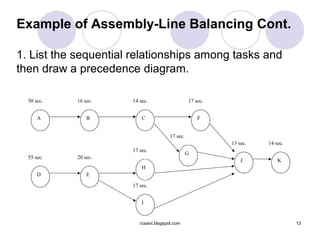

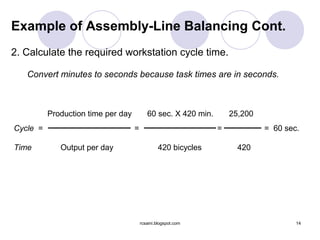

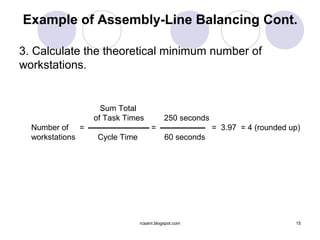

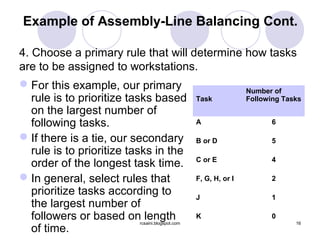

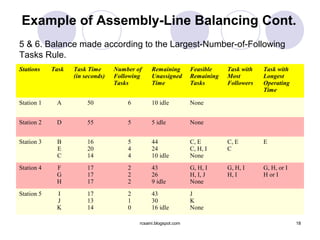

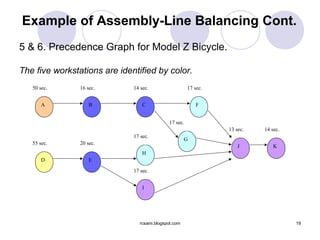

3. The document provides steps for balancing an assembly line, including determining task relationships, cycle time, number of stations, and assigning tasks based on precedence and time constraints. It includes an example to illustrate the process.