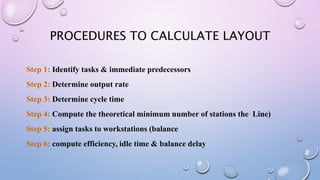

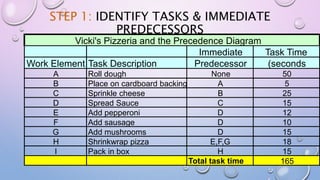

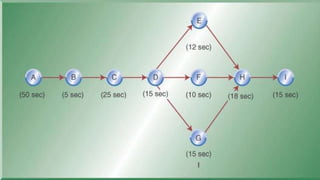

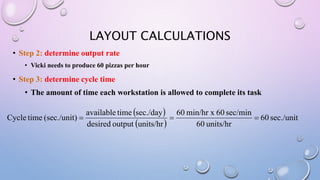

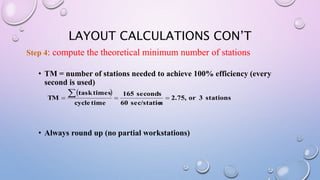

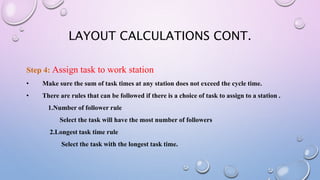

This document discusses the process of line balancing, which is determining the optimal physical arrangement of resources in a facility. The goal is to balance the workload so that each worker performs the same amount of work and no one is overburdened or waiting. The procedure involves identifying tasks and predecessors, determining the output rate, calculating cycle time, computing the minimum number of stations needed, assigning tasks to stations while ensuring the time at each station does not exceed the cycle time, and computing efficiency and idle time. An example of applying these steps to Vicki's Pizzeria is provided.