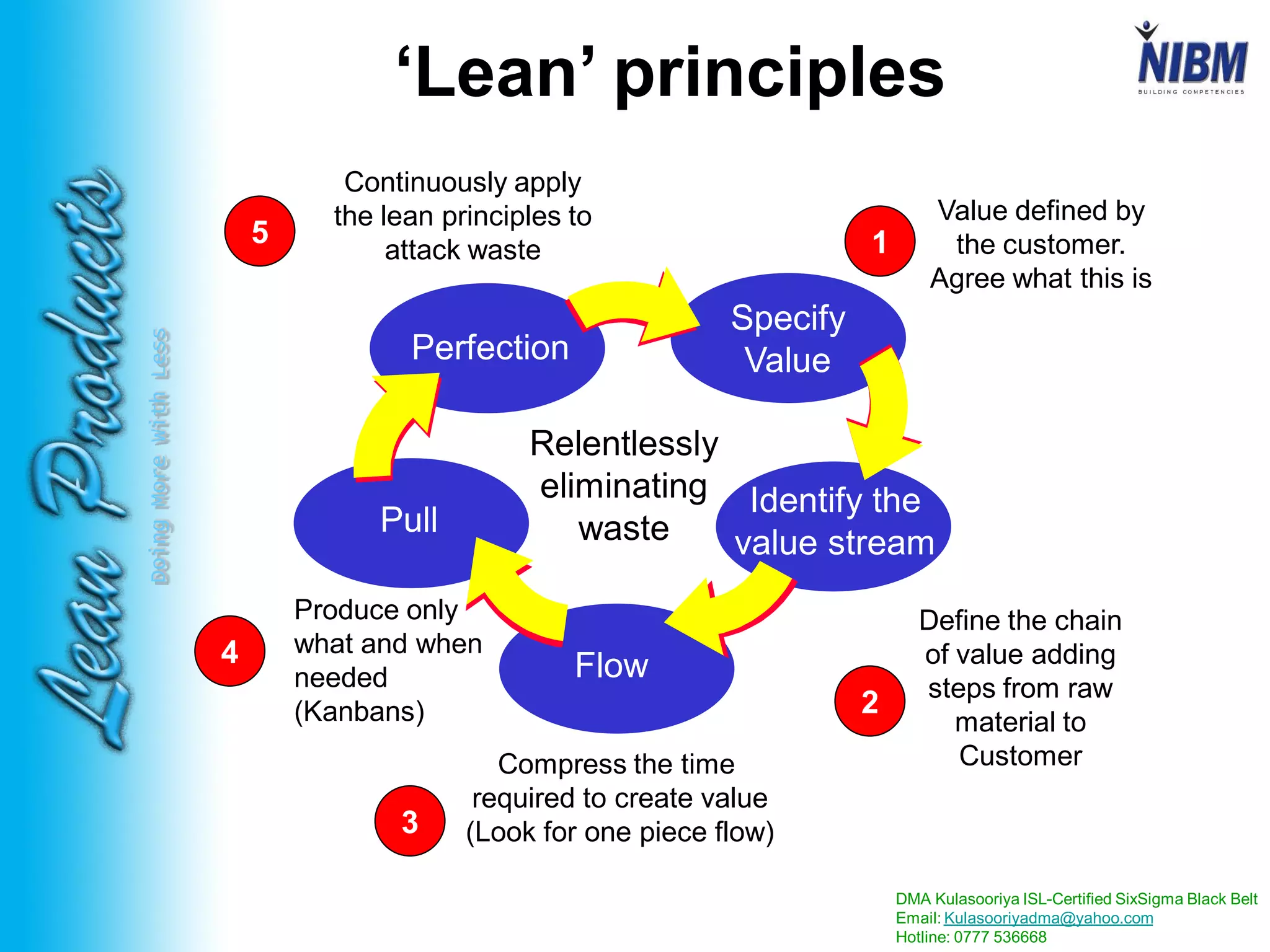

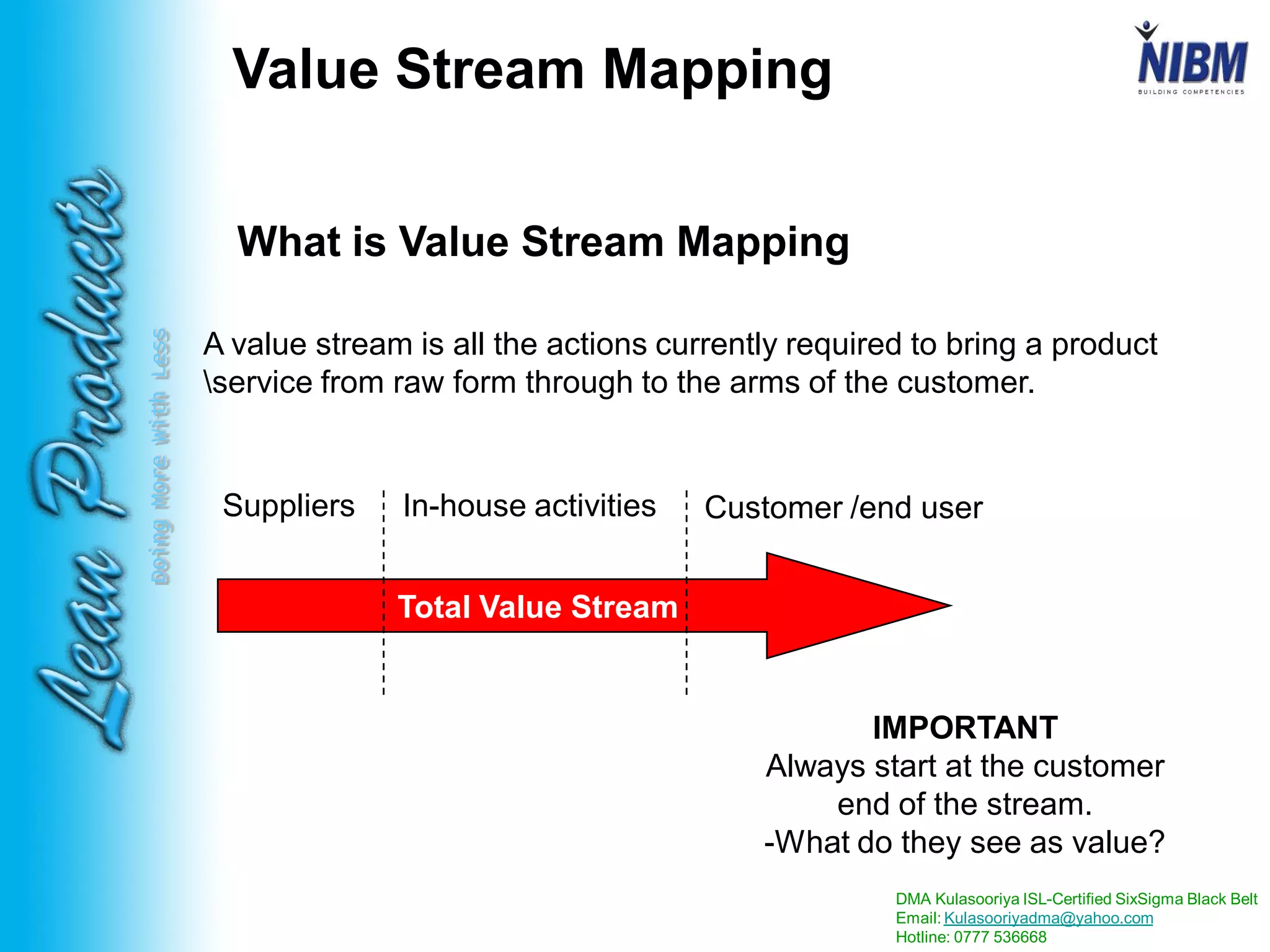

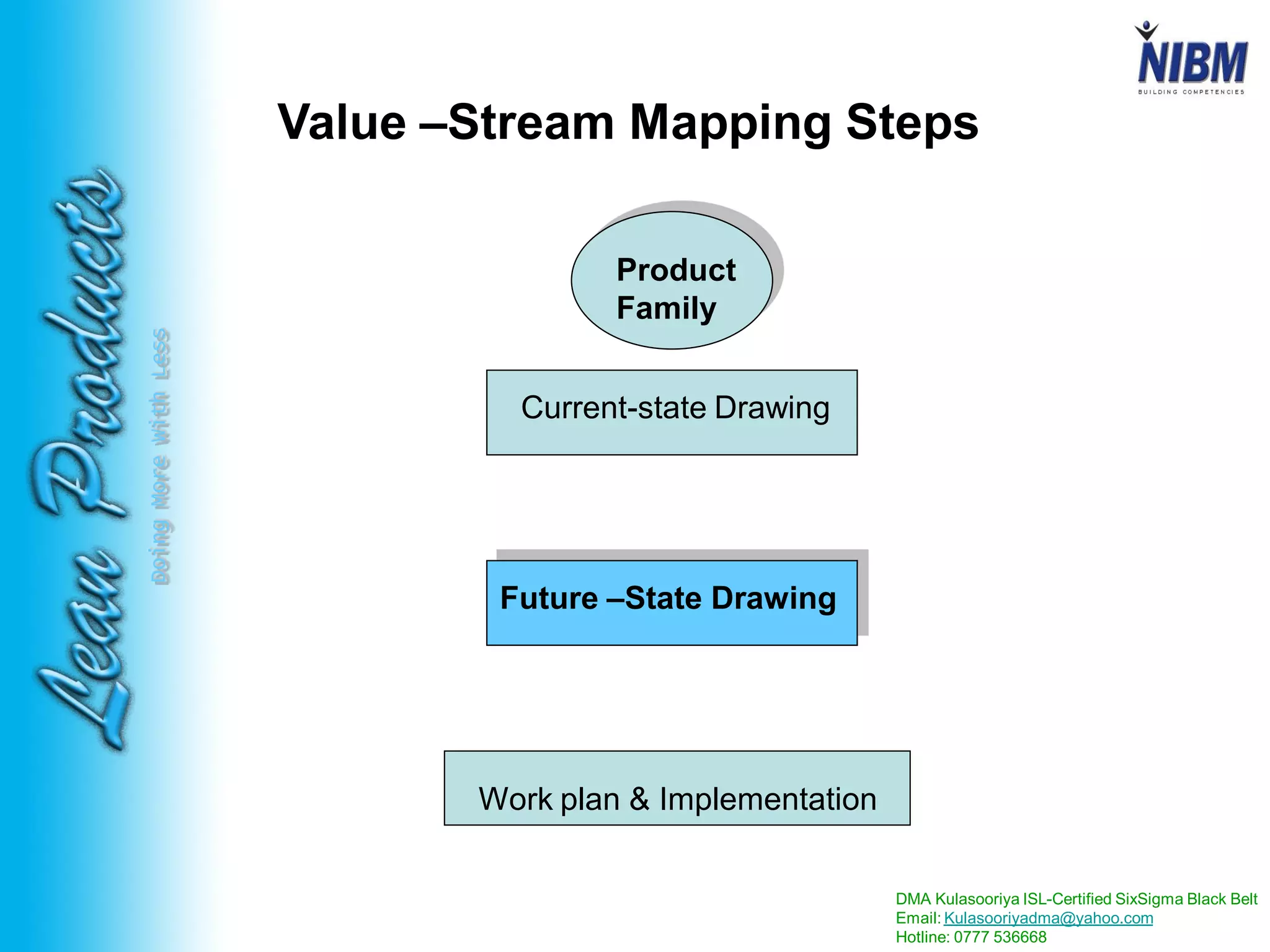

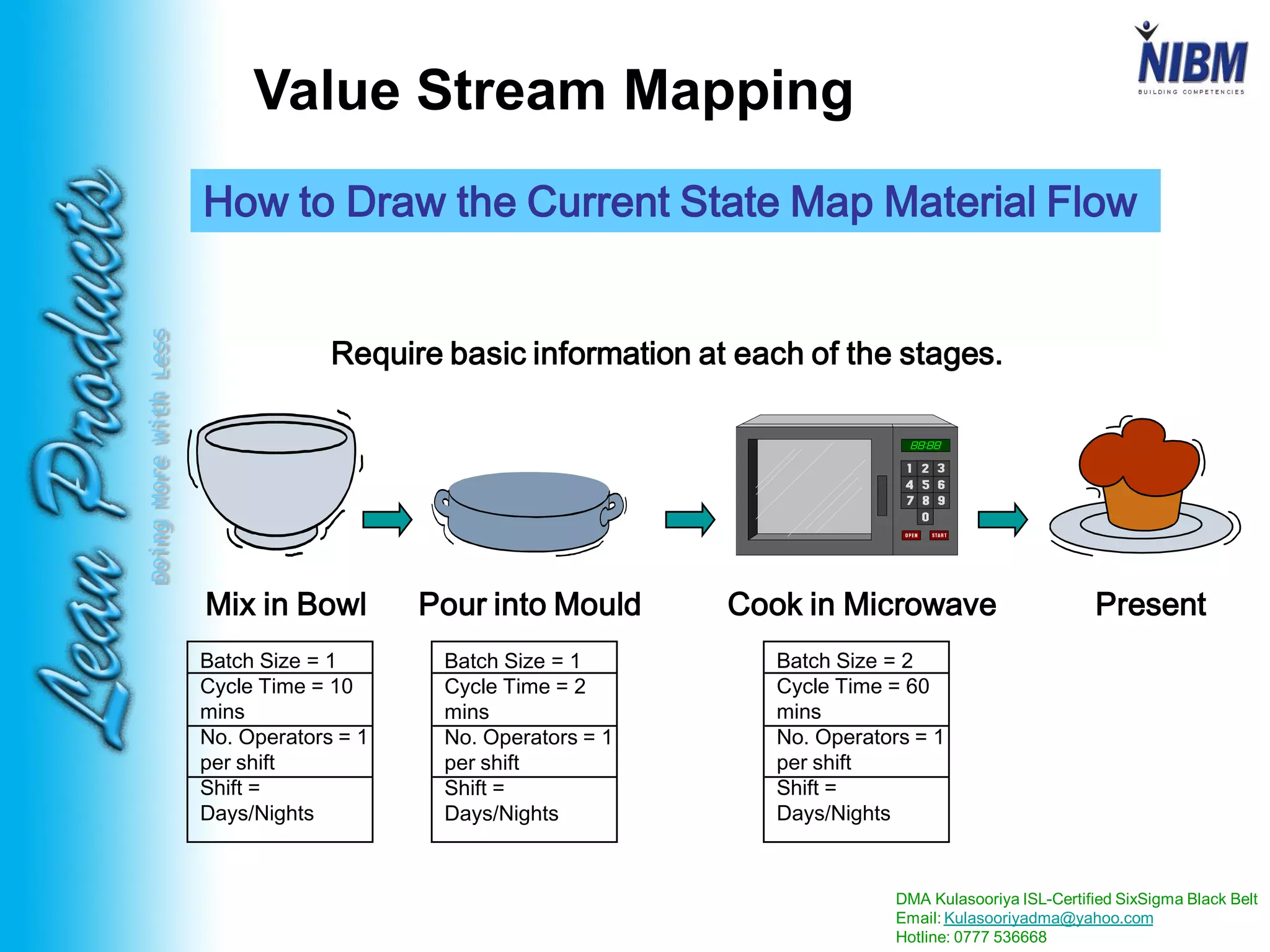

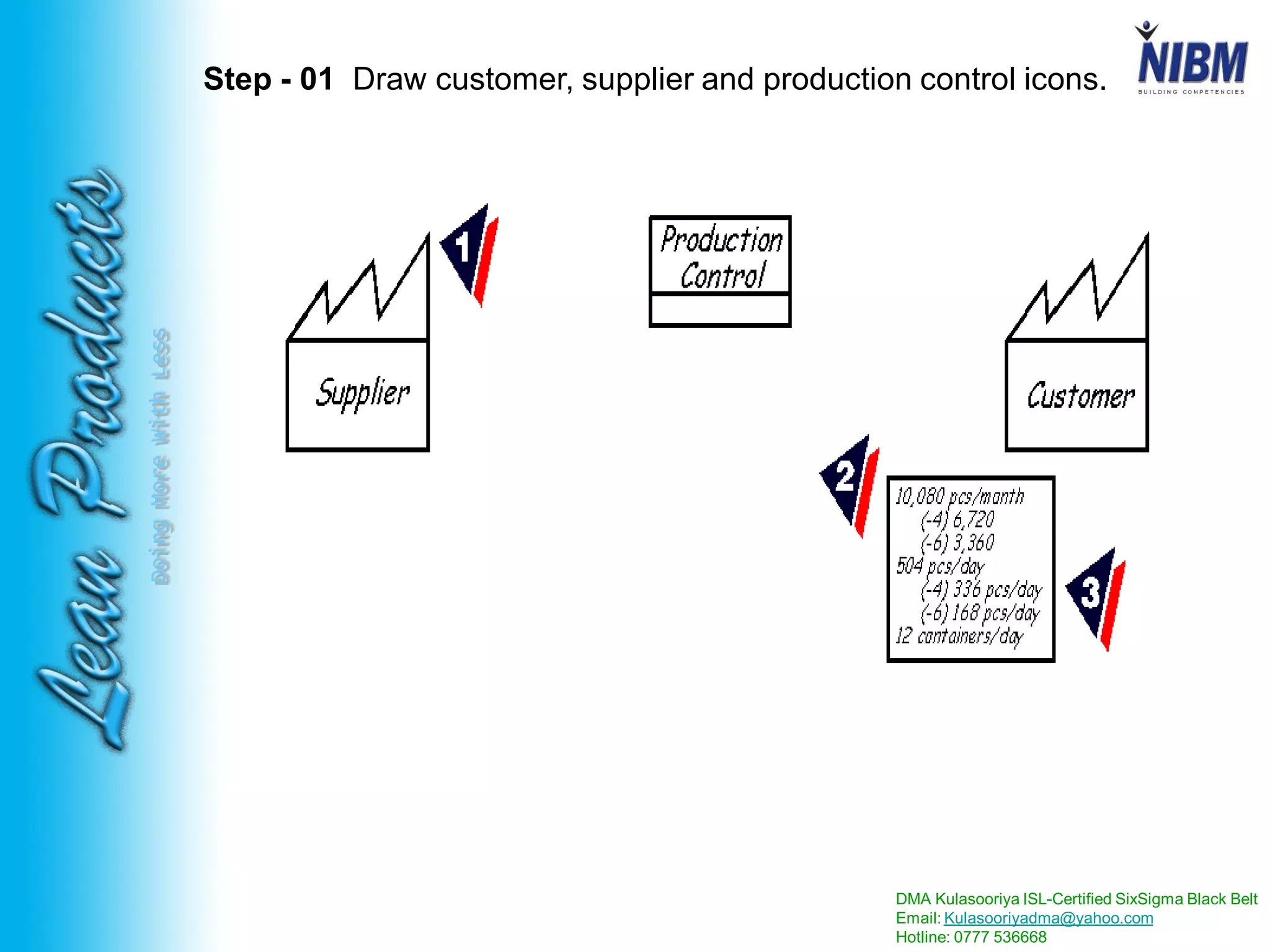

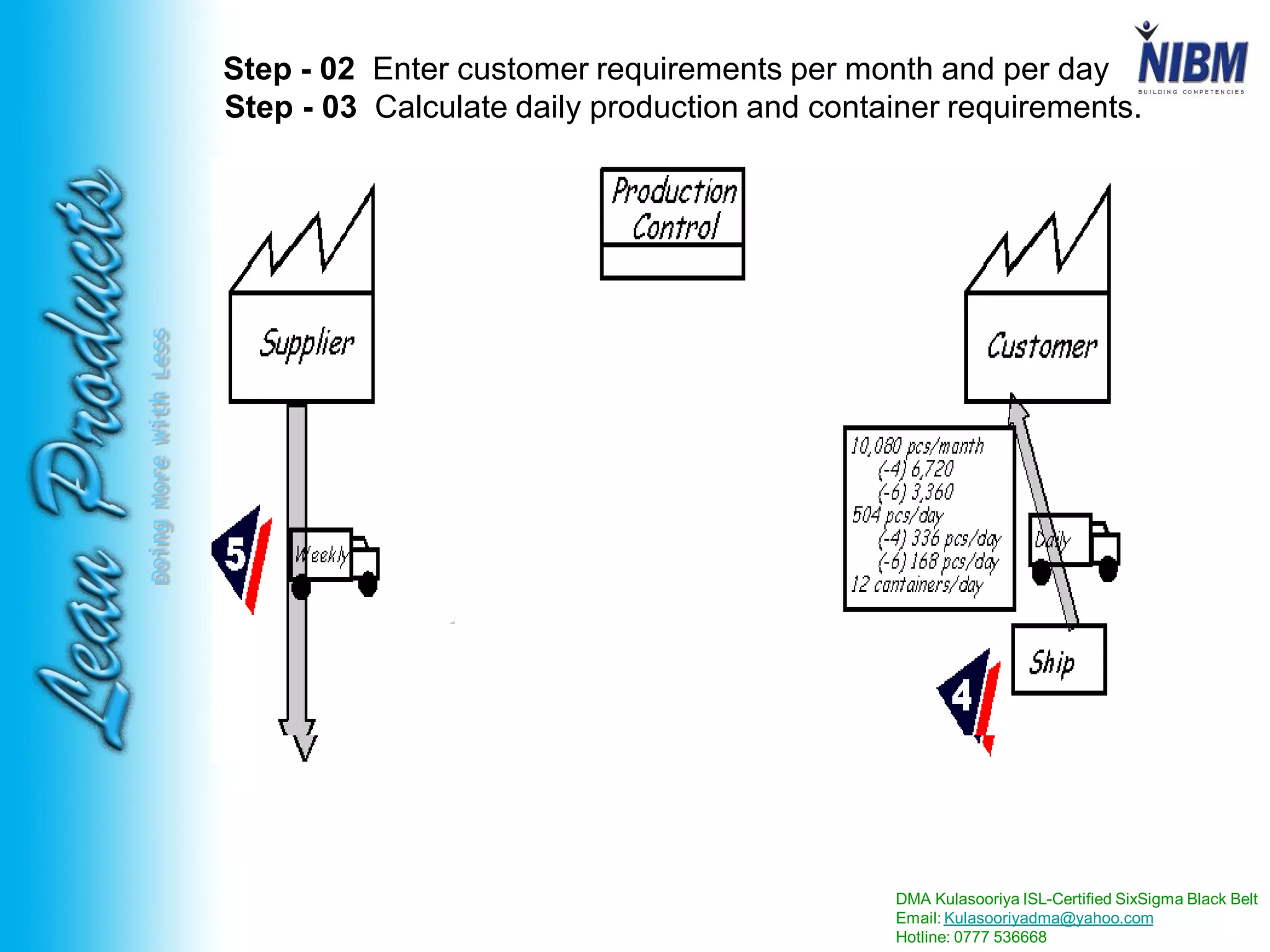

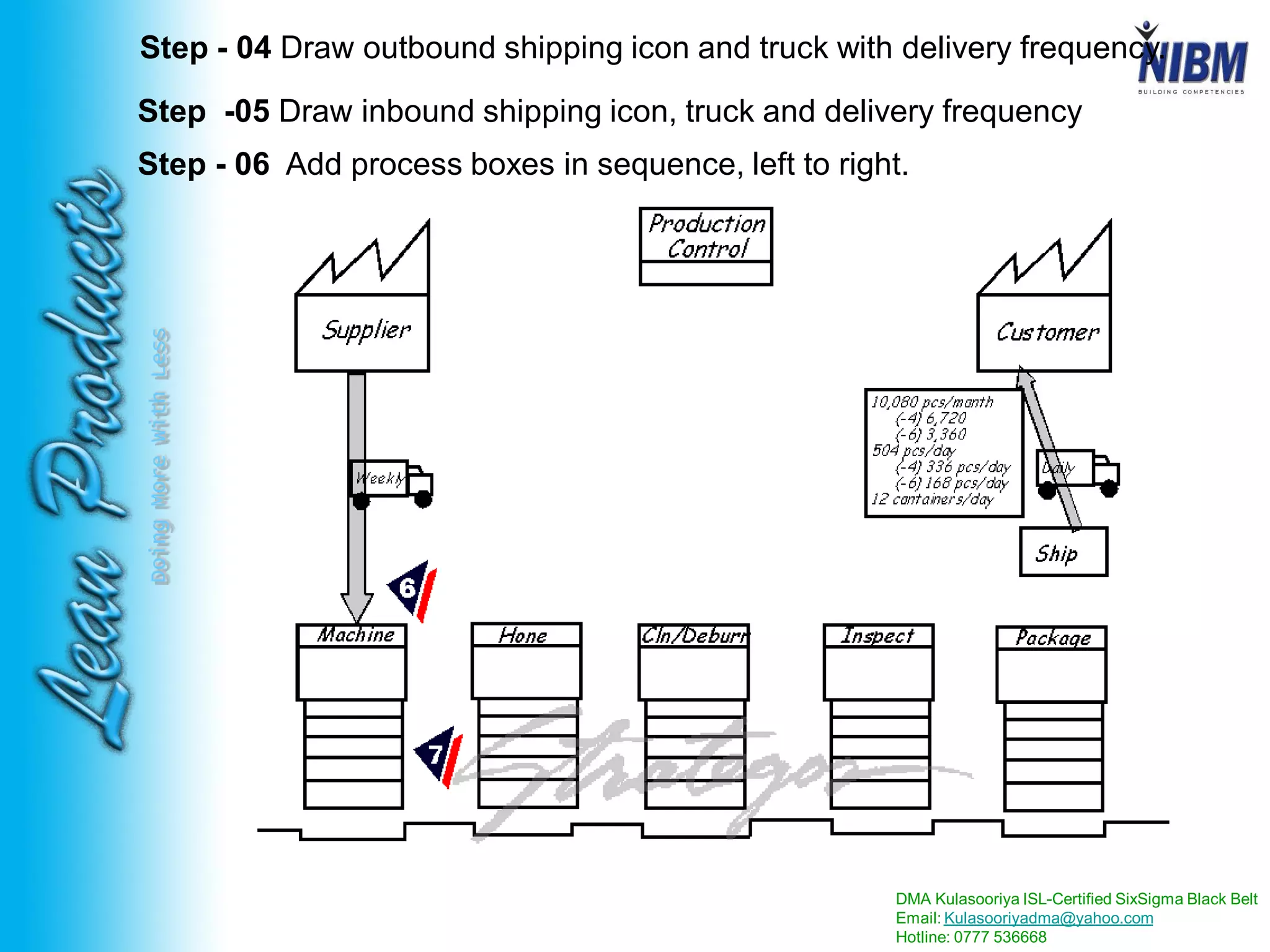

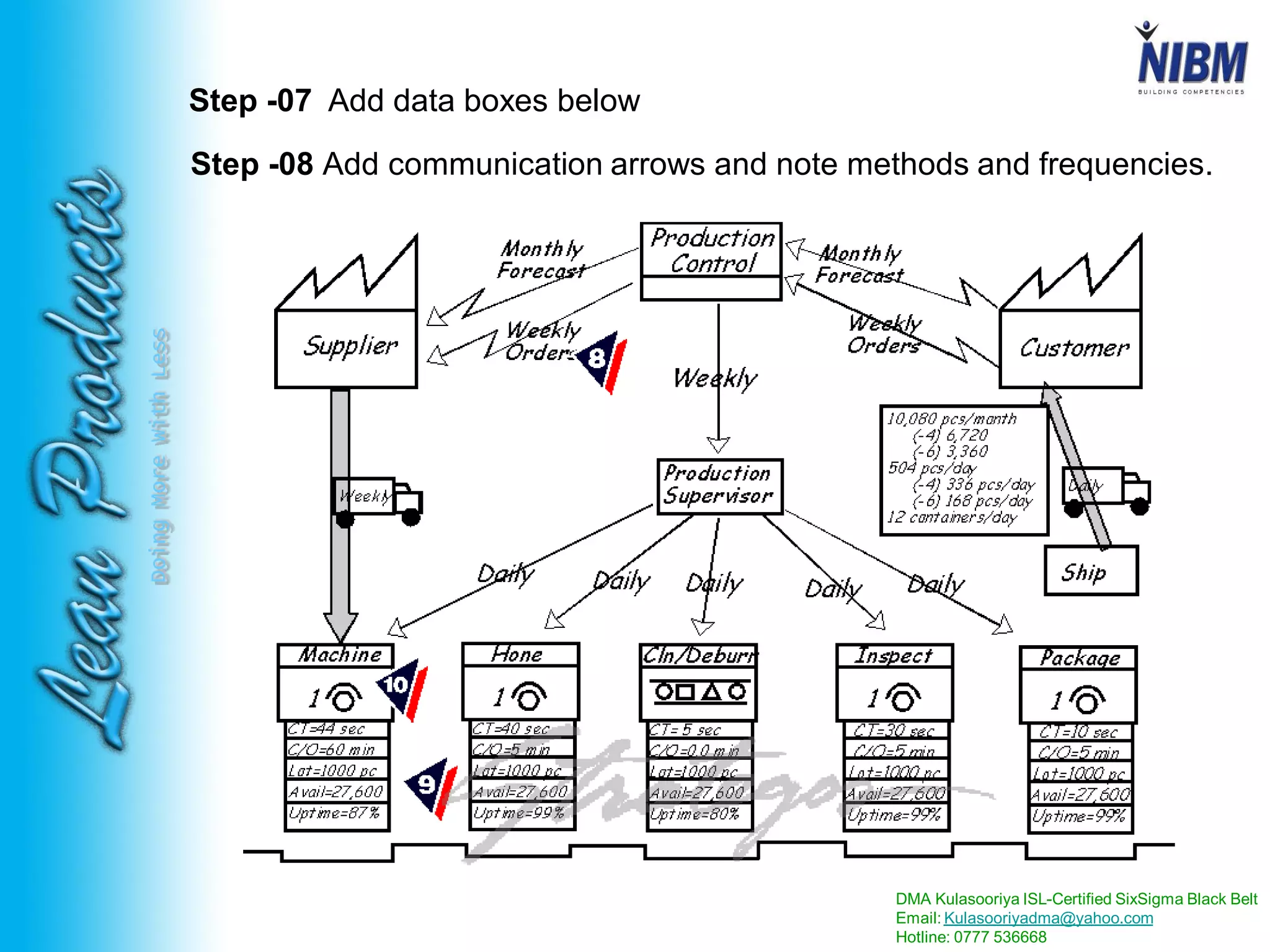

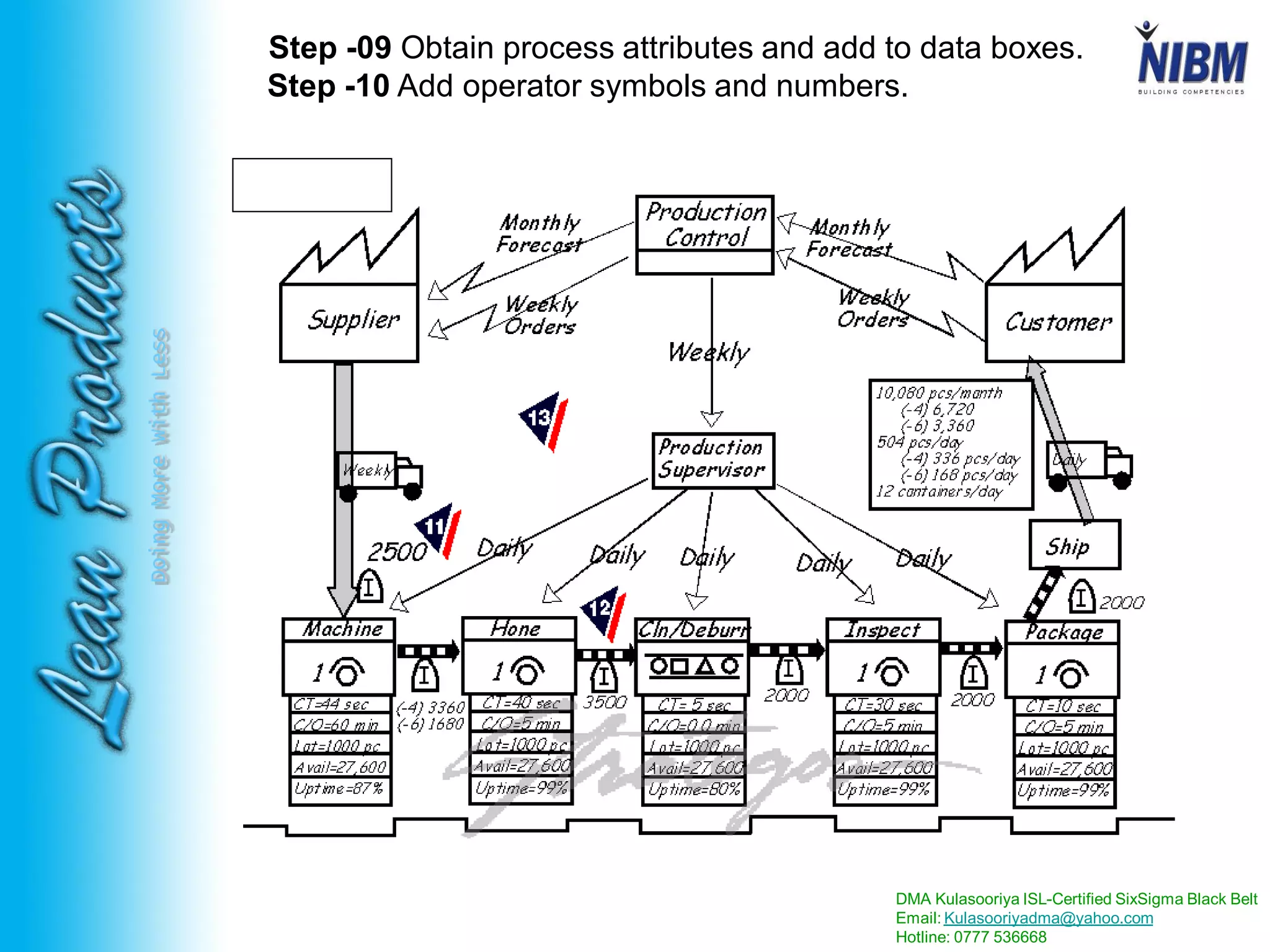

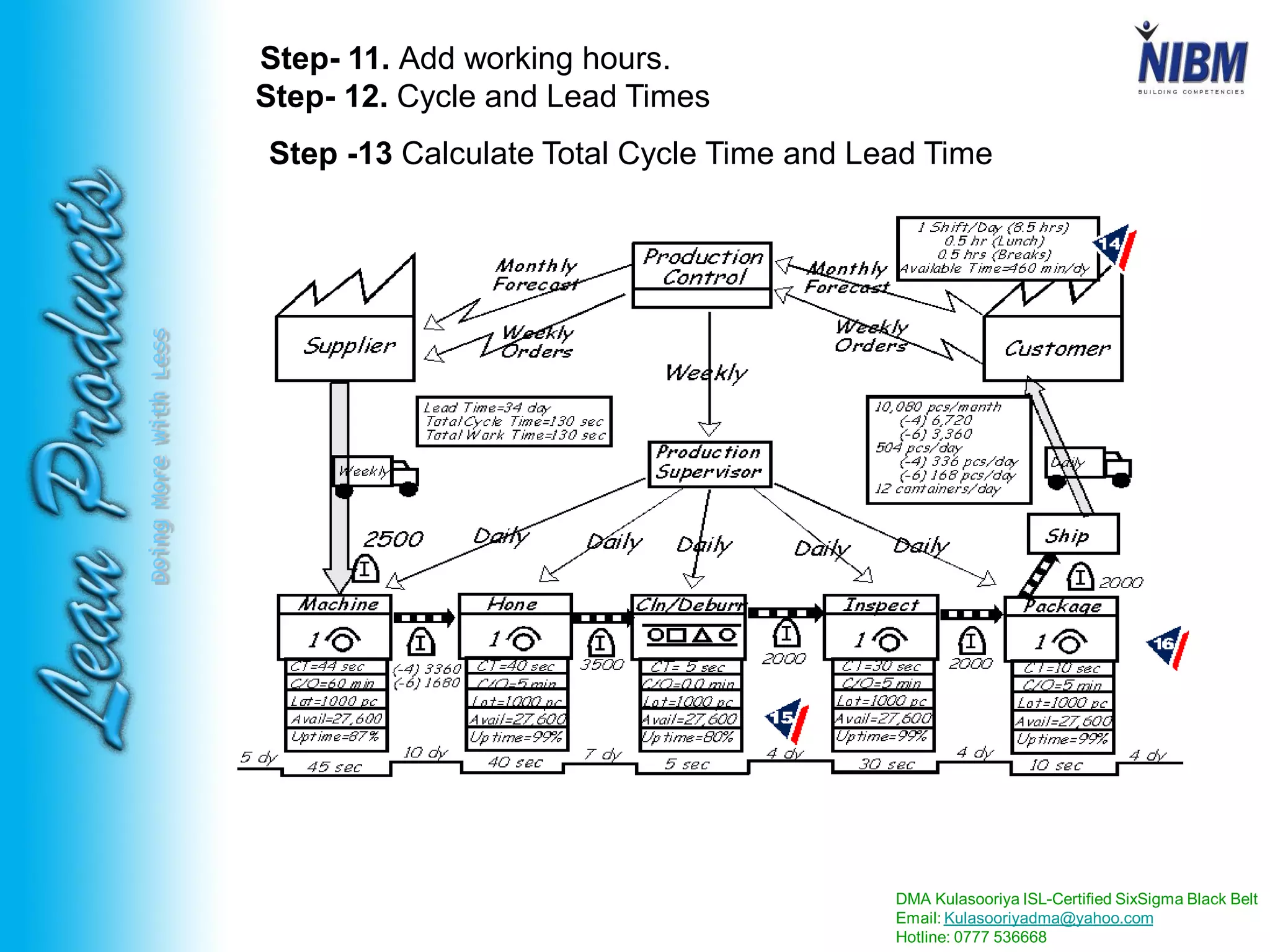

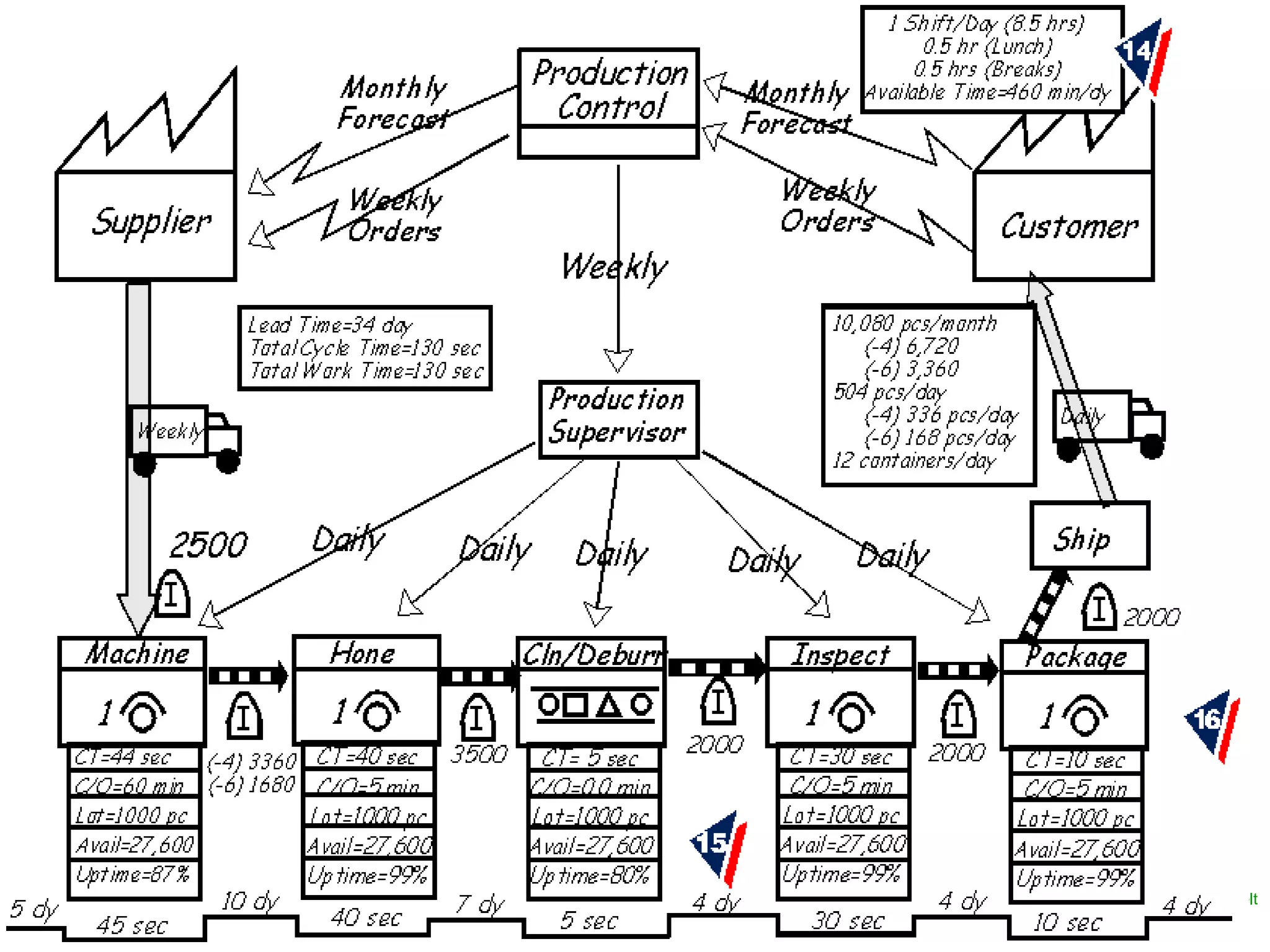

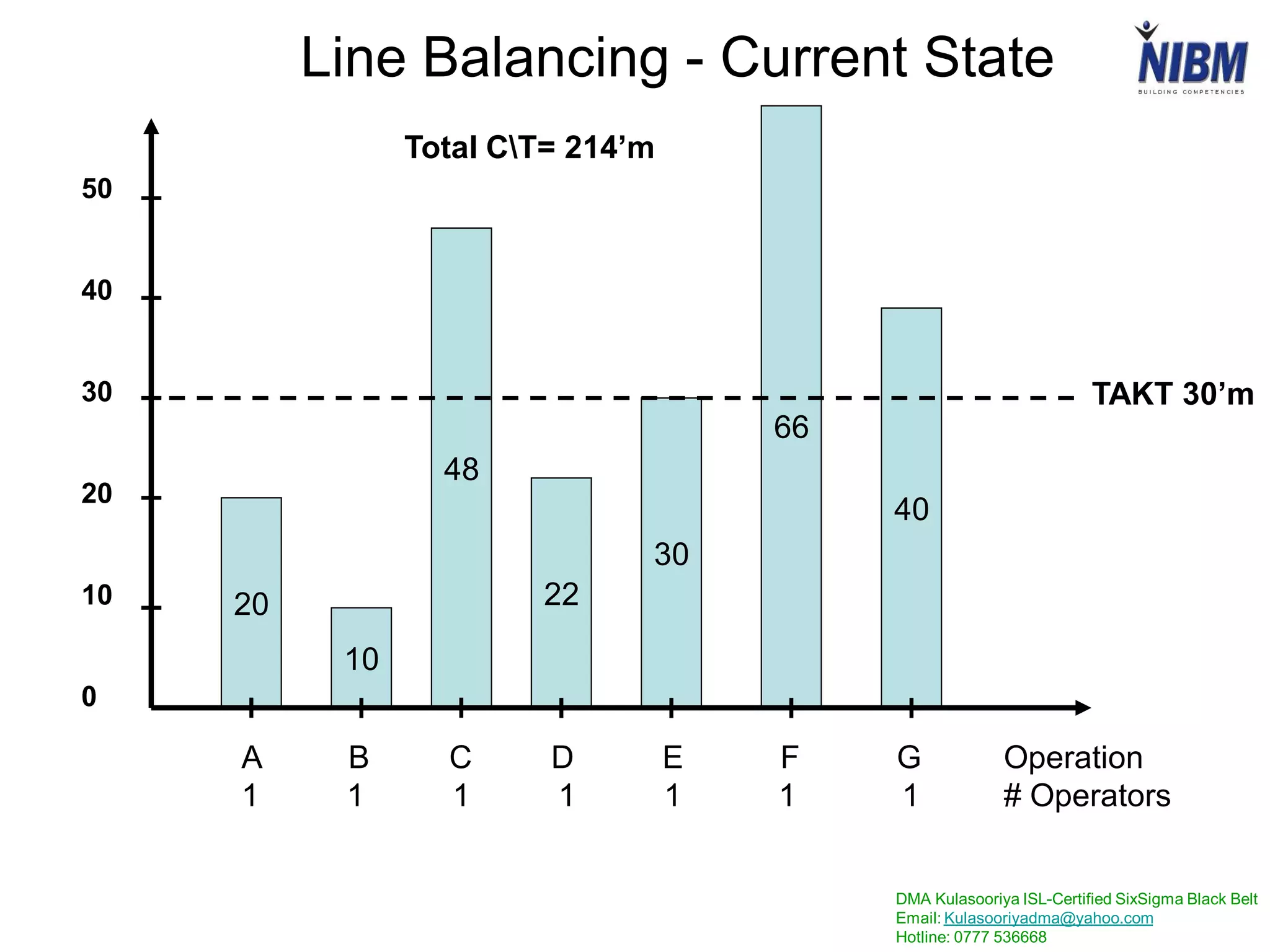

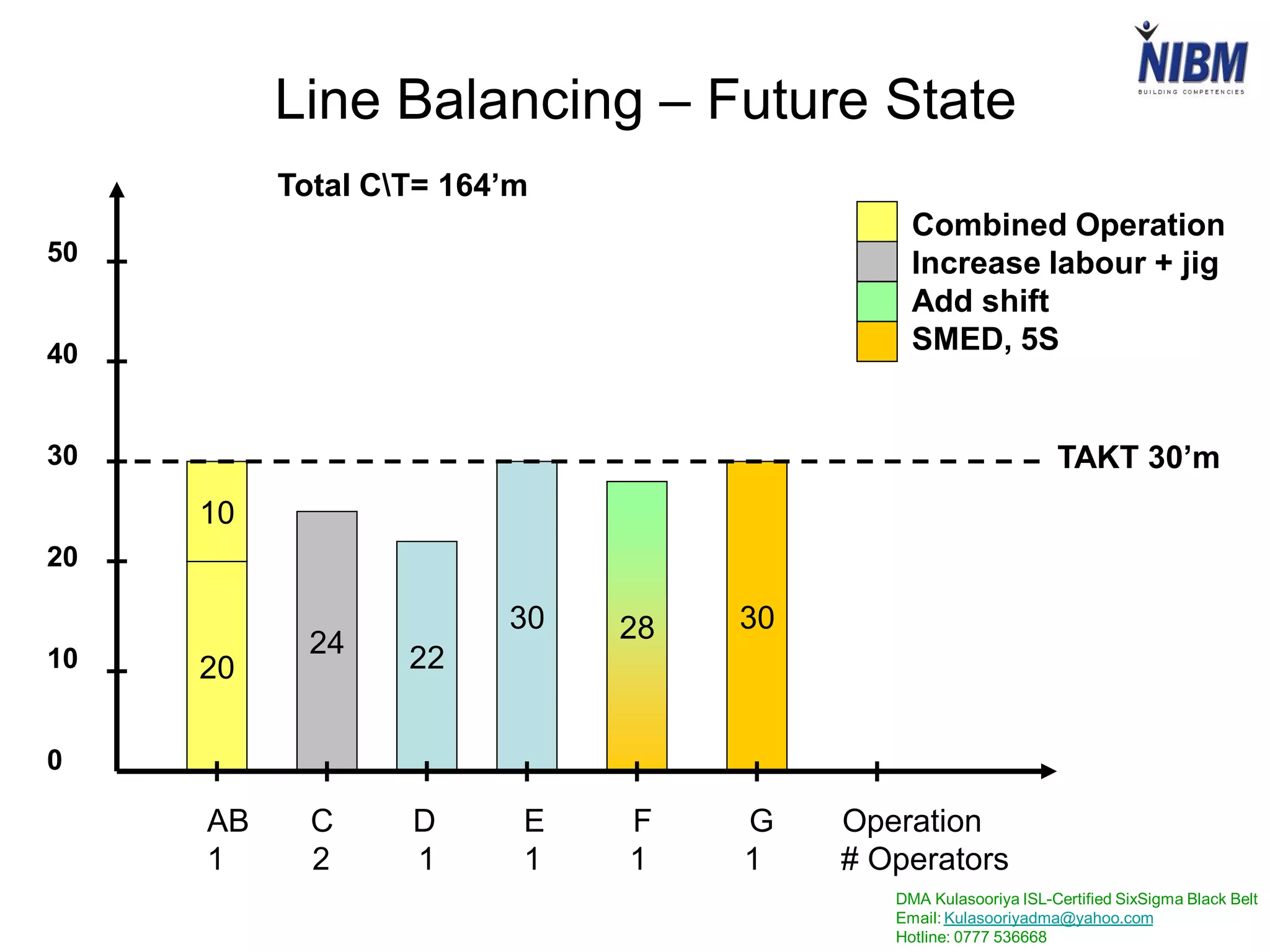

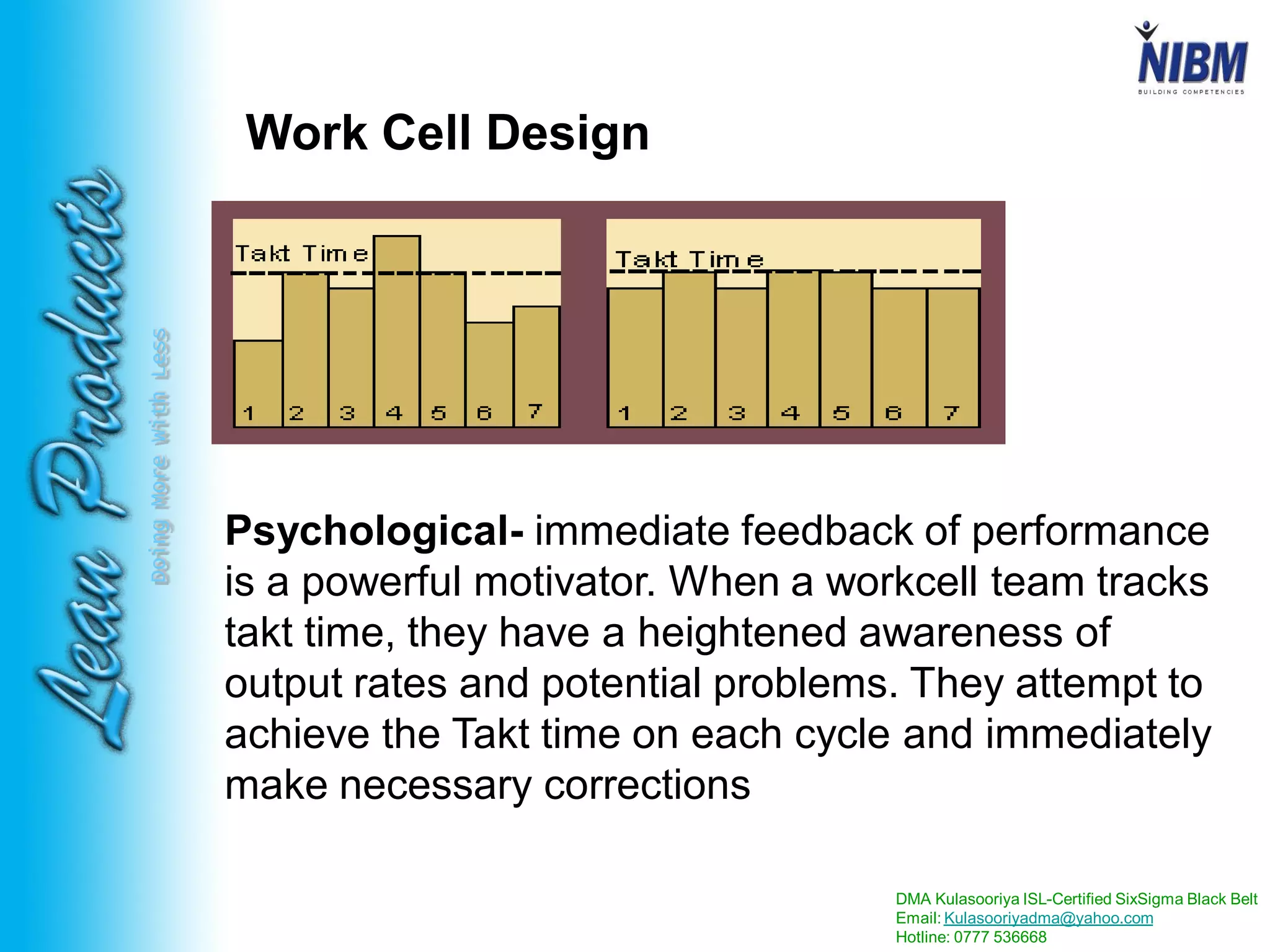

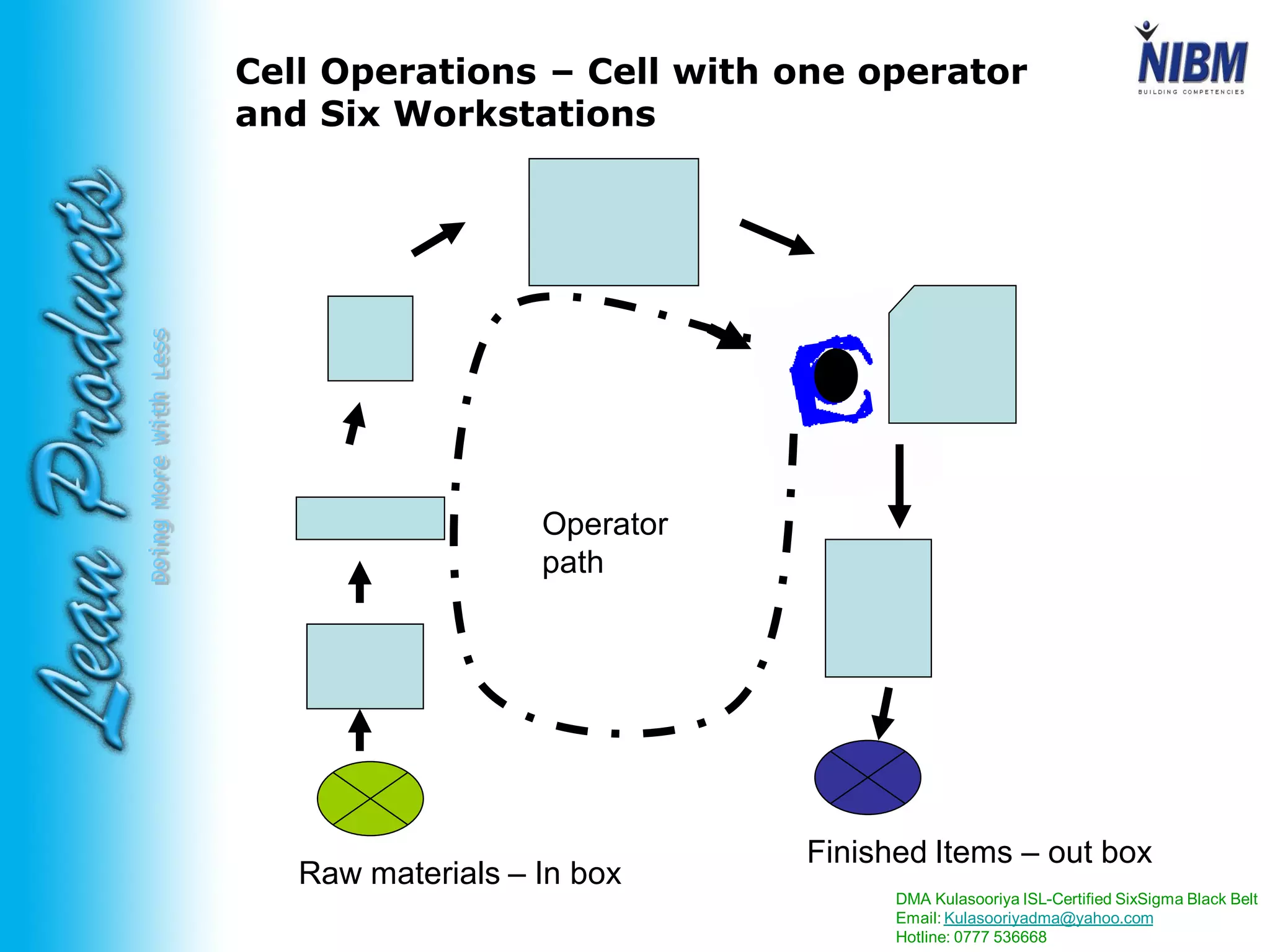

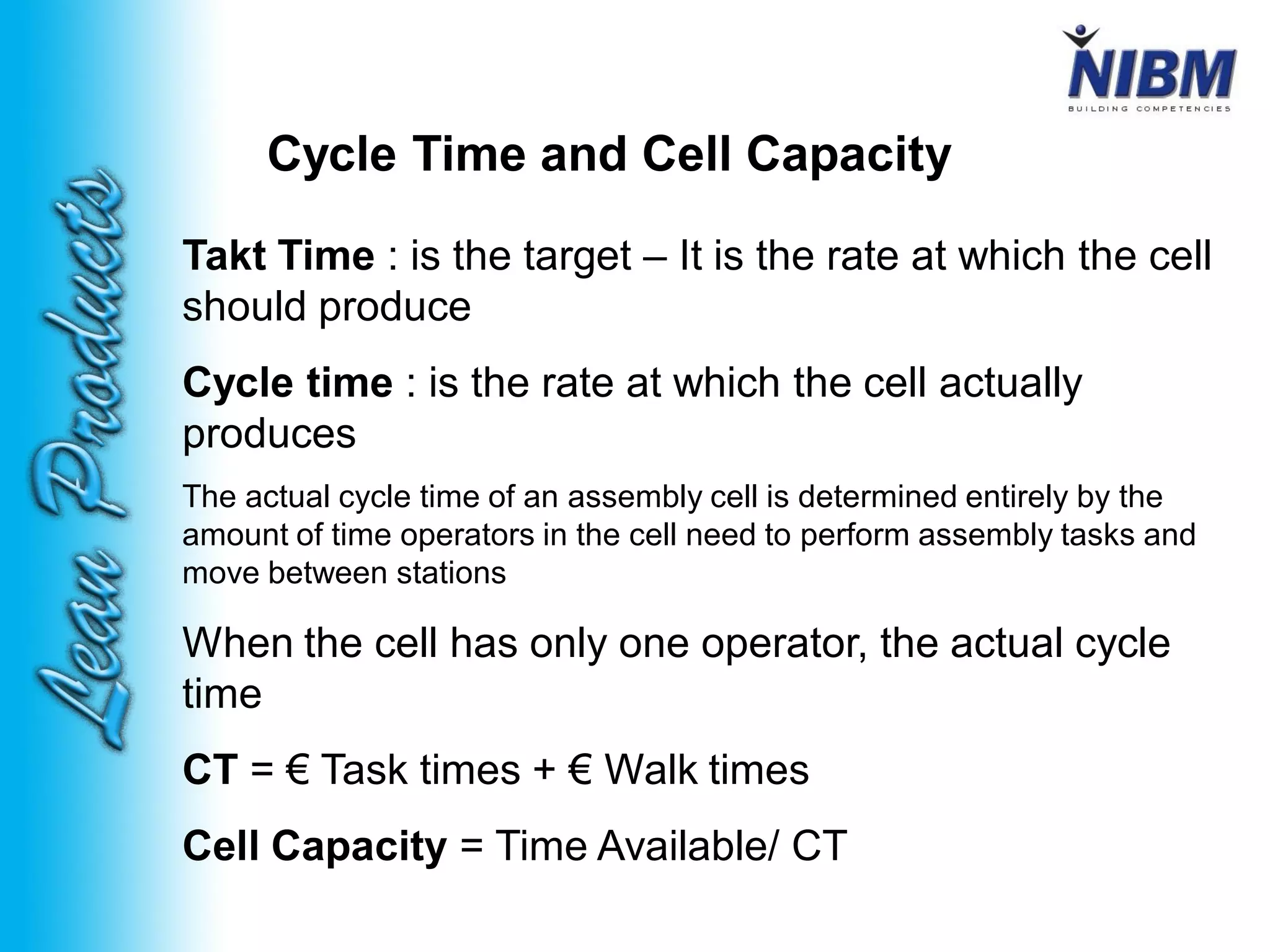

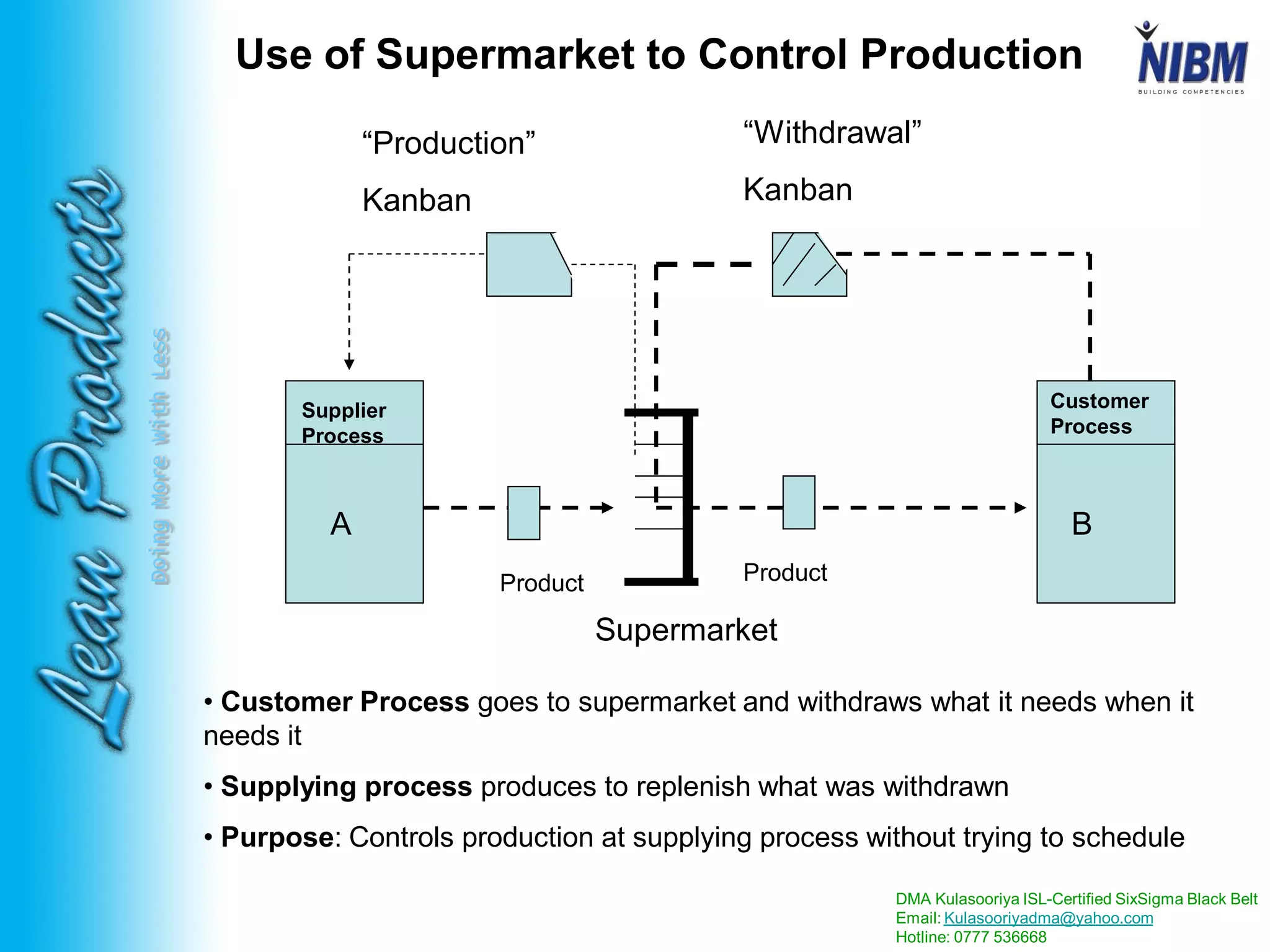

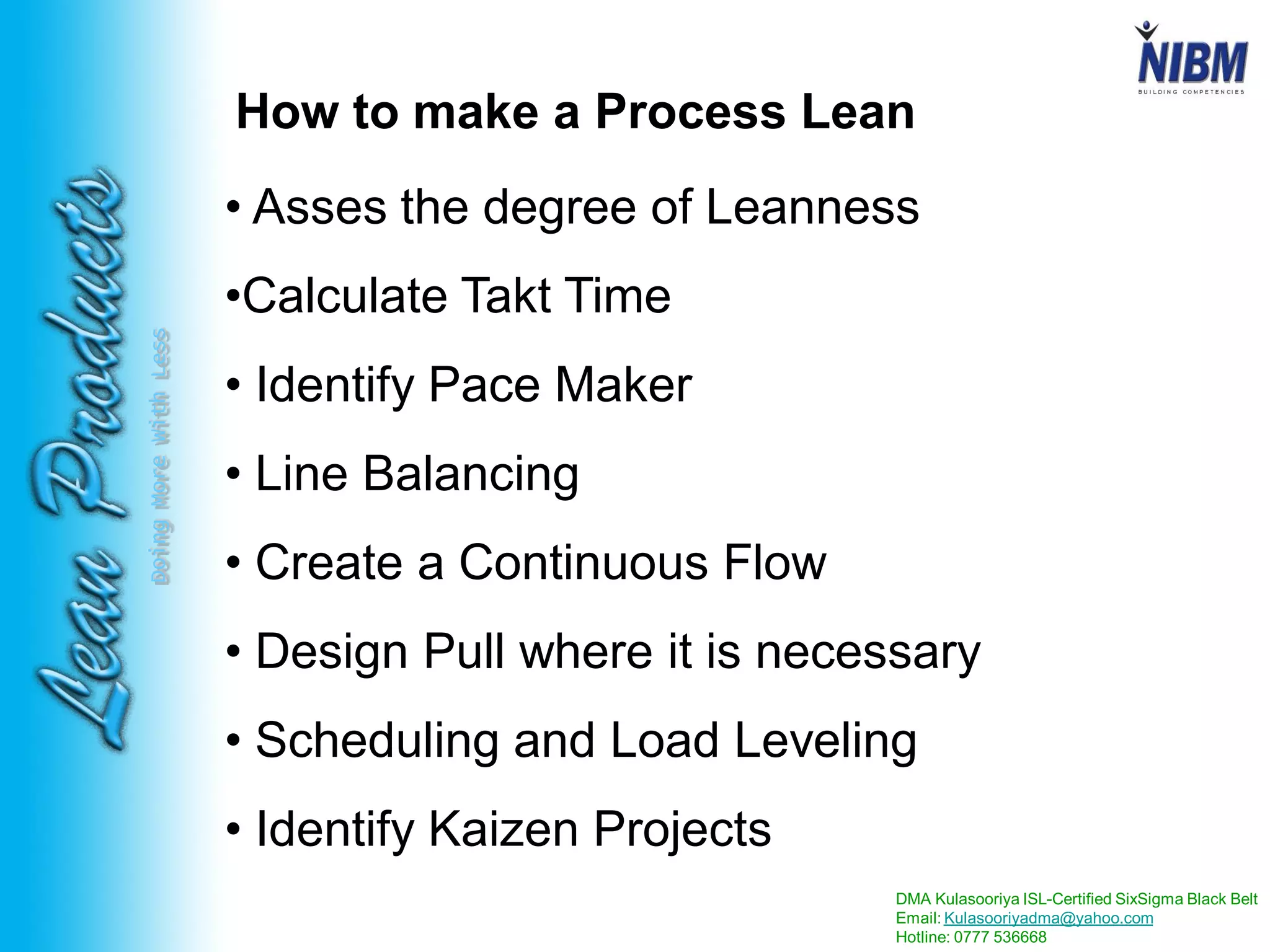

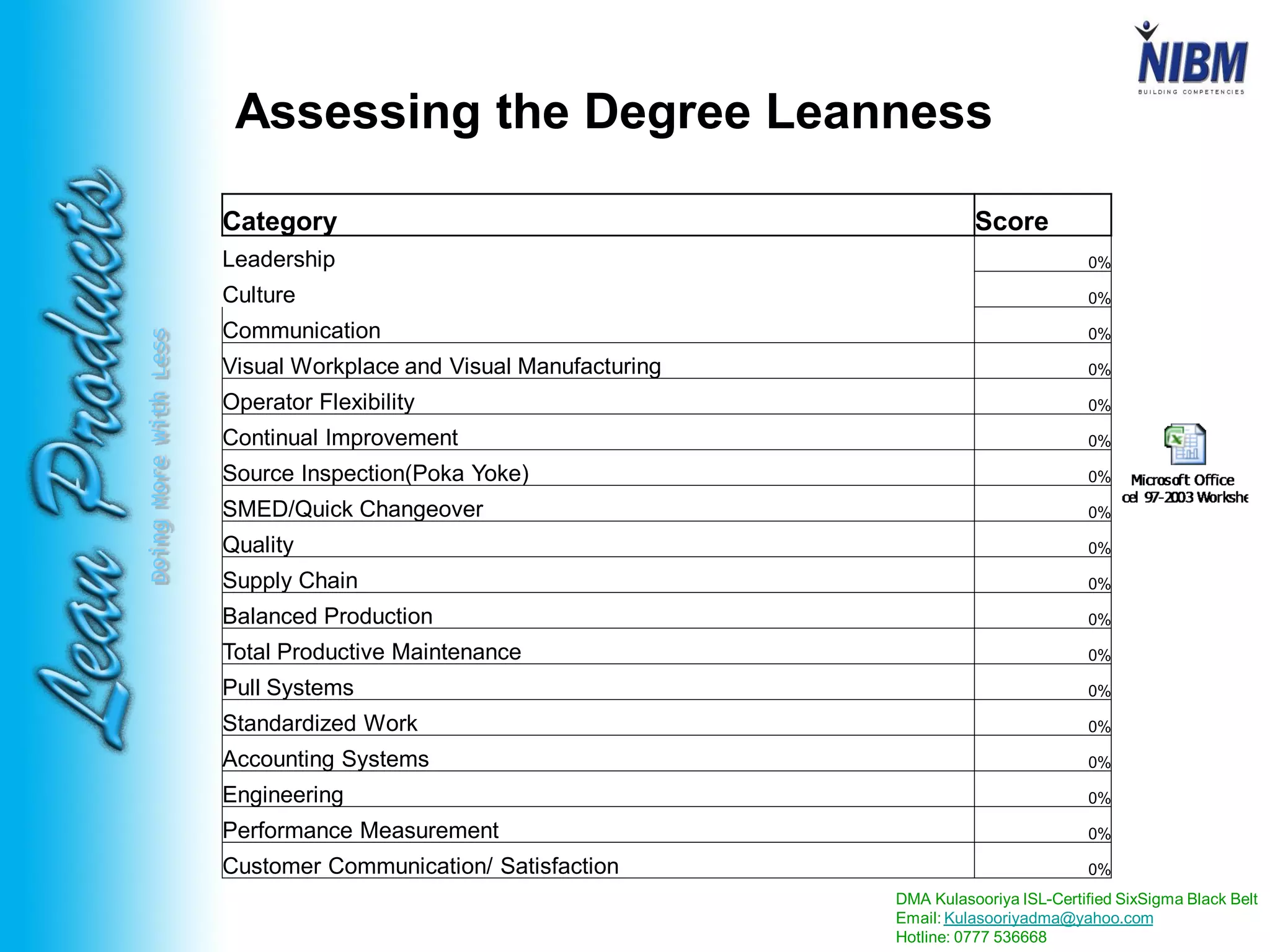

This document contains information about DMA Kulasooriya, who is an ISL-Certified Six Sigma Black Belt consultant for lean practices. It discusses lean principles and tools like value stream mapping, which is a tool to help visualize and streamline work processes. It provides information on identifying value-added versus non-value-added activities. Additionally, it covers lean concepts like takt time, which synchronizes production pace to match customer demand, and the benefits of developing continuous flow where possible.