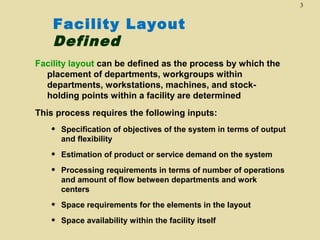

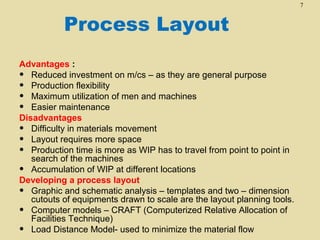

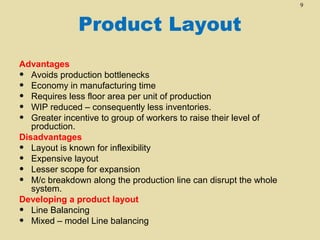

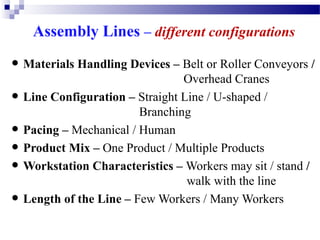

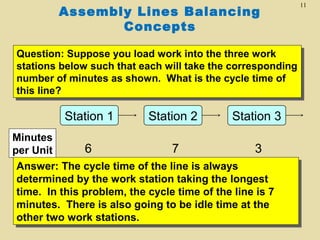

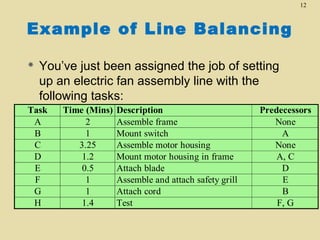

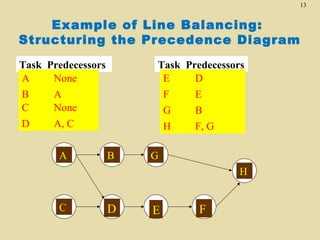

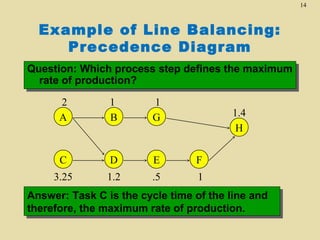

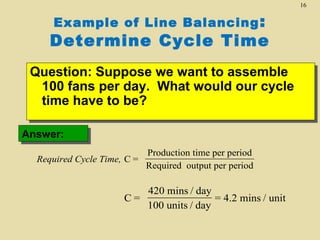

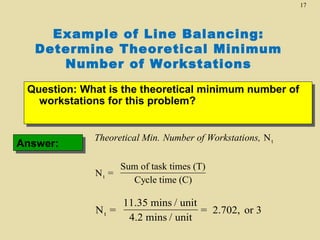

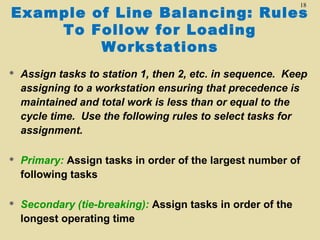

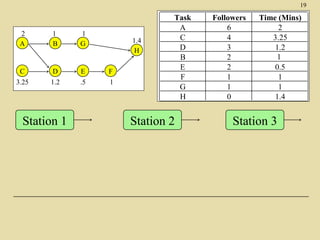

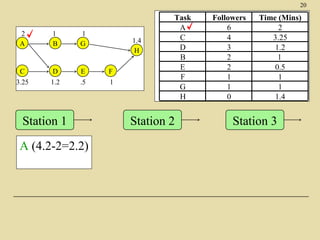

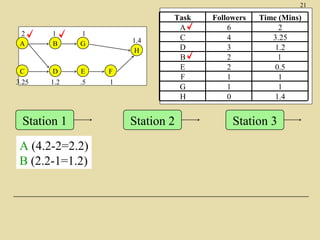

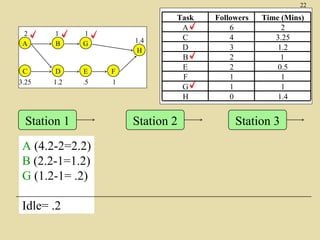

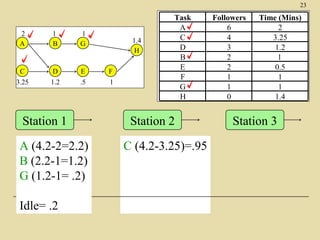

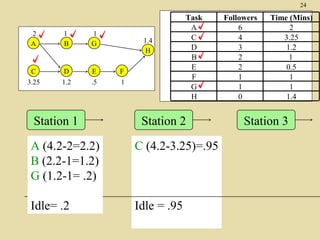

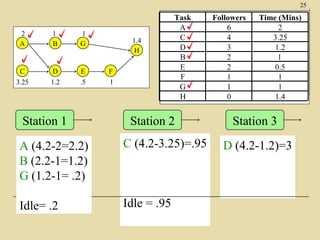

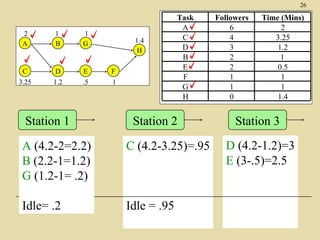

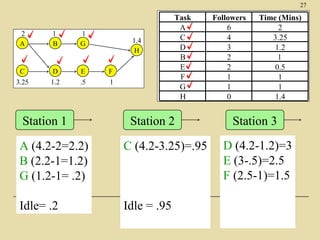

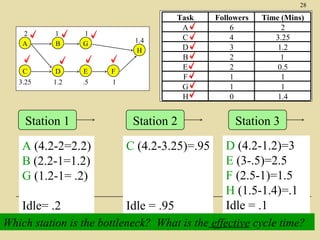

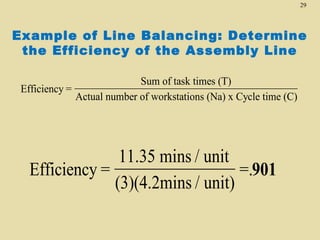

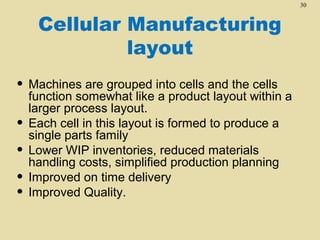

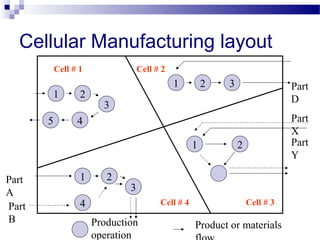

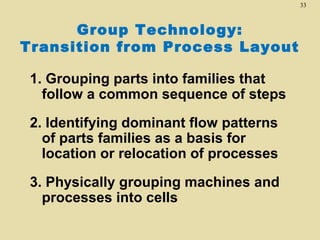

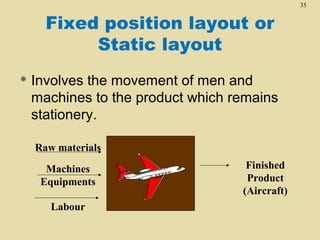

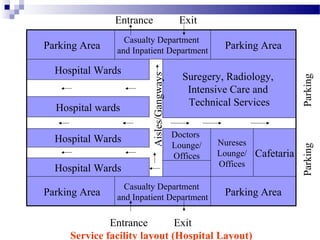

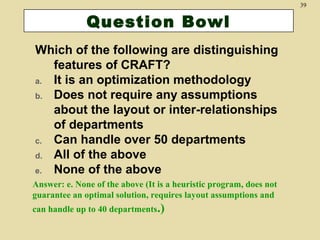

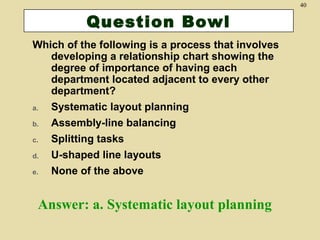

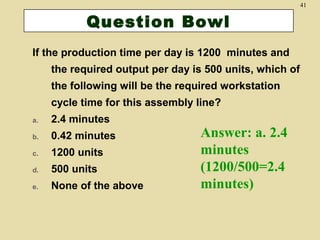

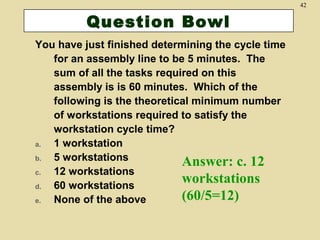

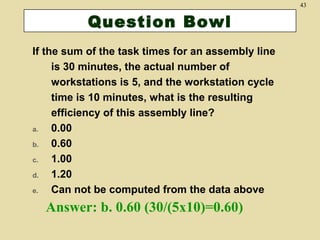

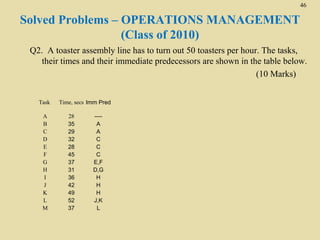

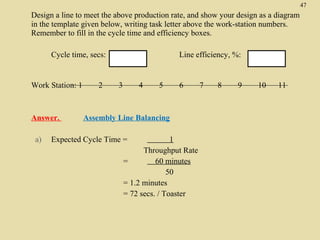

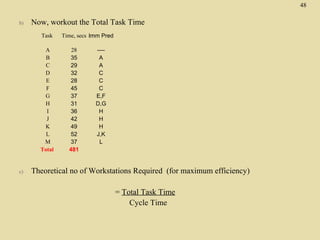

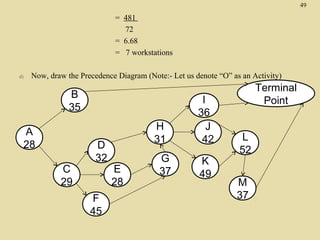

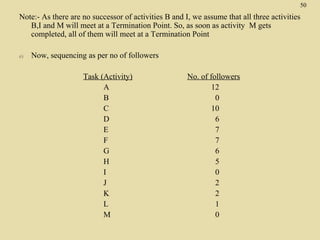

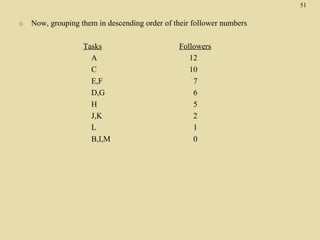

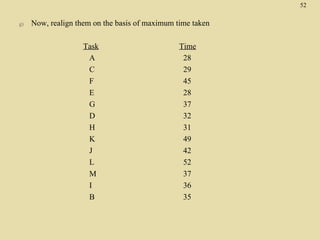

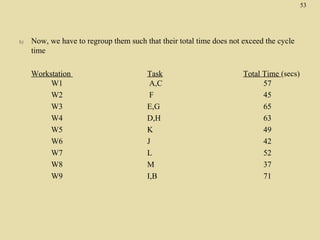

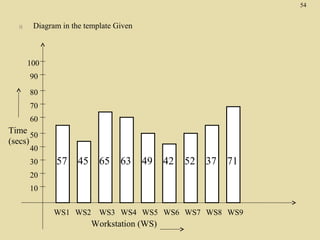

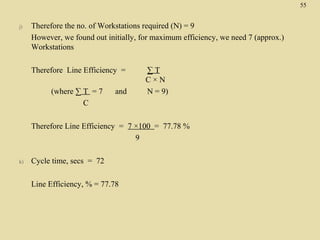

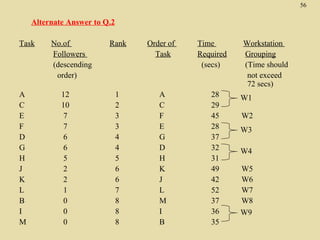

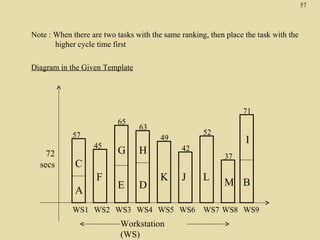

This document discusses various facility layout concepts and approaches. It begins by defining facility layout as the process of determining the placement of departments, workgroups, workstations, machines, and stockholding points within a facility based on objectives, demand estimates, processing requirements, and space constraints. The document then covers criteria for a good layout, basic layout formats including process, product, group technology, and fixed-position layouts. It provides examples of developing process and product layouts, including the use of computer models, line balancing concepts, and cellular manufacturing layouts. The key objectives are to optimize material flow, worker efficiency, flexibility, and space utilization.