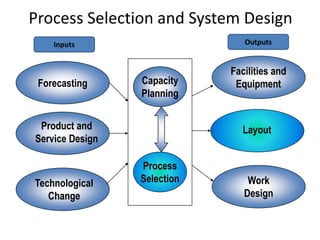

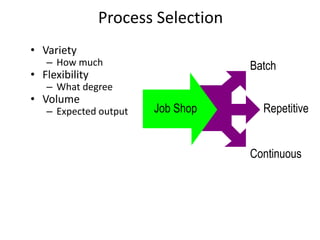

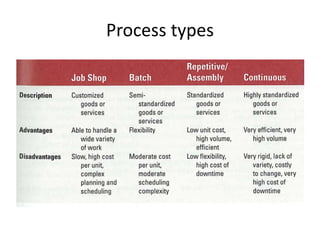

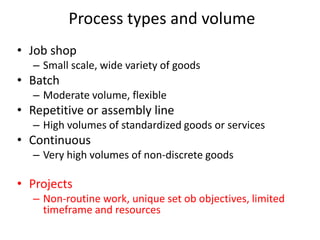

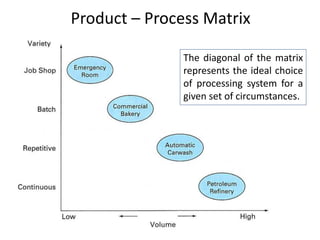

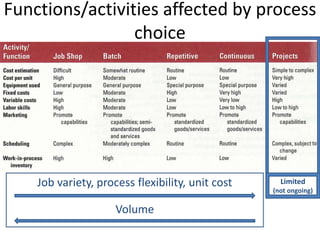

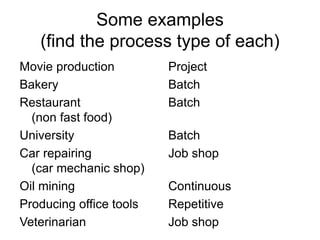

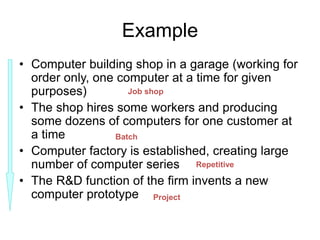

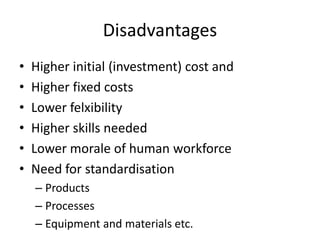

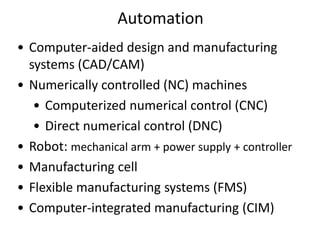

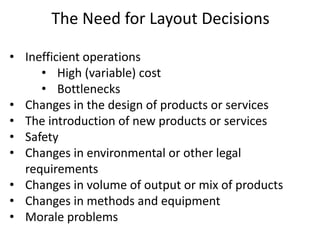

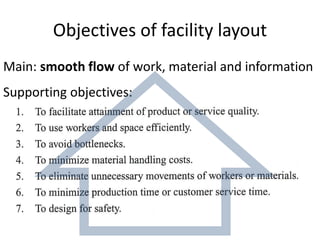

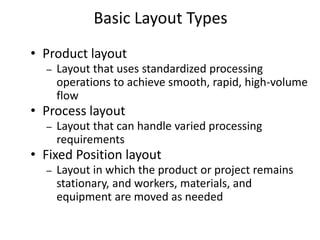

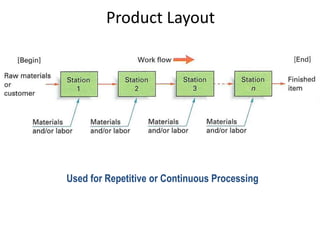

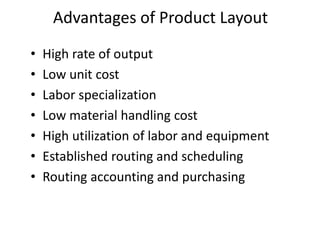

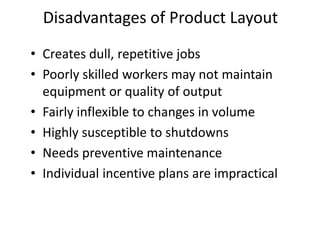

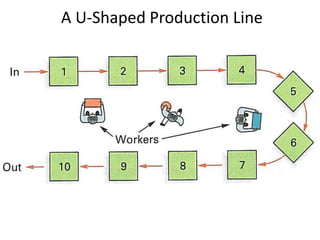

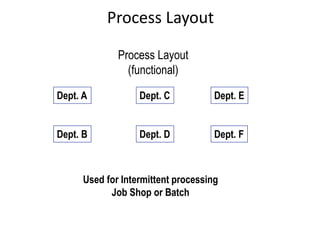

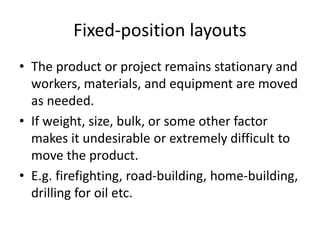

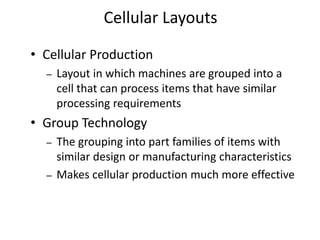

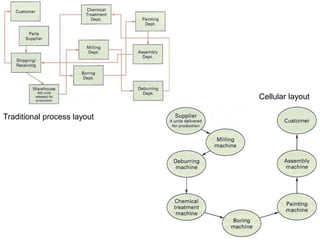

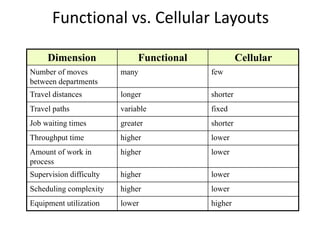

This document discusses process selection and facility layout. It begins by defining process selection as deciding how production will be organized in terms of capacity planning, facility layout, equipment, and work design. It then describes the key aspects and types of process strategies such as capital intensity, flexibility, design, volume, and technology. The main process types are defined as job shop, batch, repetitive/assembly line, continuous, and projects. Product-process matrices and examples of different industries are provided. The functions affected by process choice and examples of production life cycles are summarized. The document concludes by outlining objectives for facility layout design and describing basic layout types including product, process, and fixed-position layouts.