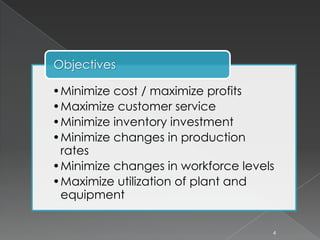

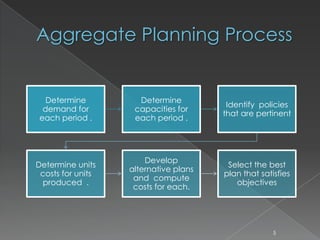

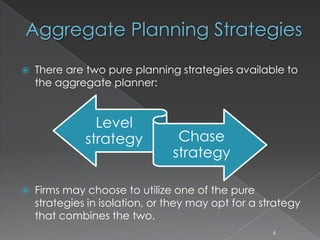

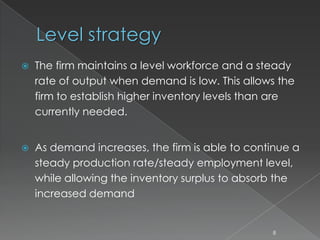

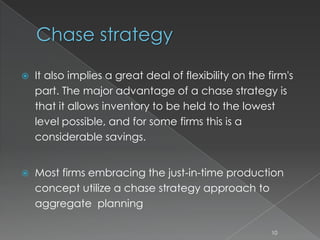

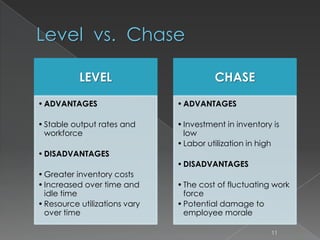

Aggregate planning involves developing a preliminary production schedule over the next 6-18 months to satisfy forecasted demand at minimum cost. It considers targeted sales, production levels, inventory levels and backlogs. The objectives are to minimize costs and changes while maximizing profits, customer service and resource utilization. Common strategies are level, which maintains steady output/employment, or chase, which matches demand period to period. Techniques to develop plans include linear programming, linear decision rules and simulation models.