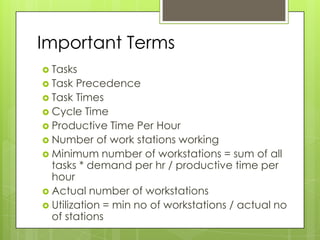

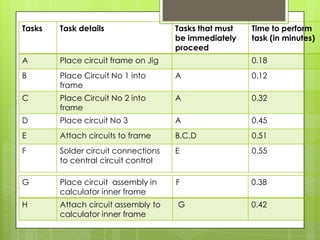

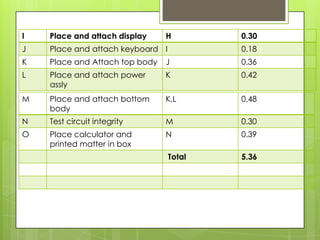

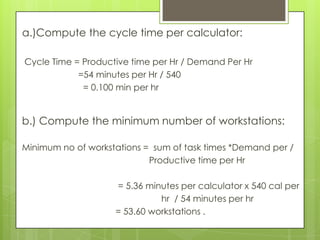

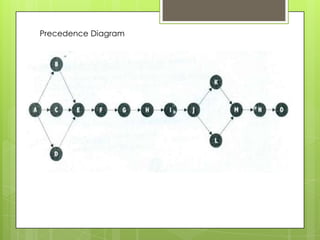

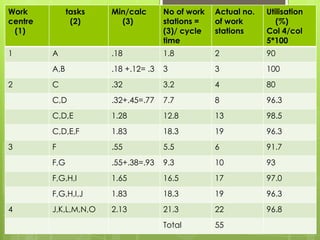

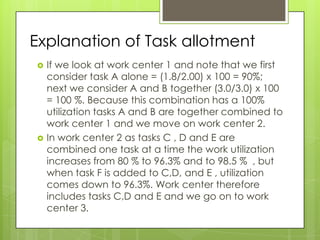

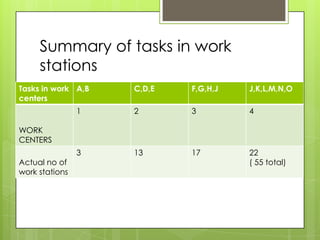

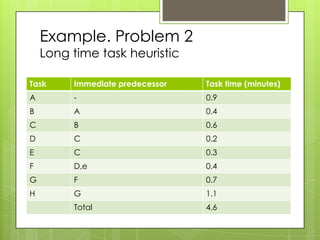

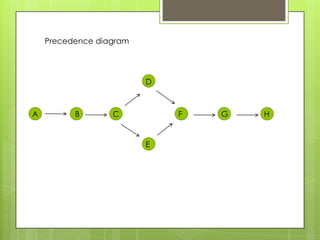

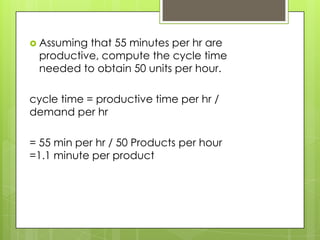

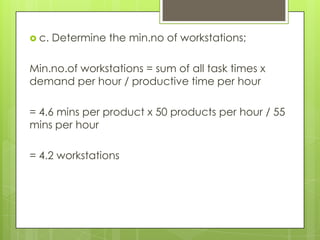

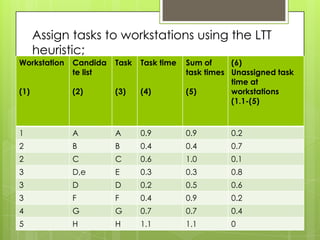

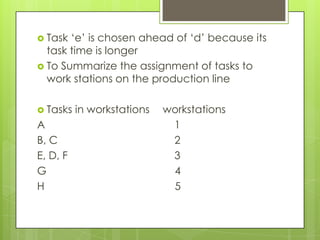

Line balancing is a process that levels the workload across production processes to eliminate bottlenecks and excess capacity. It involves determining tasks, task times, precedence, cycle time, and minimum workstations needed. Two common heuristics for assigning tasks to workstations are incremental utilization, which adds tasks one by one, and longest task time, which prioritizes longer tasks. The example demonstrates calculating cycle time and workstations needed before using the heuristics to propose an assignment of tasks to stations.