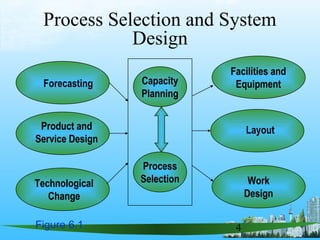

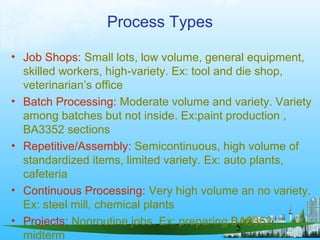

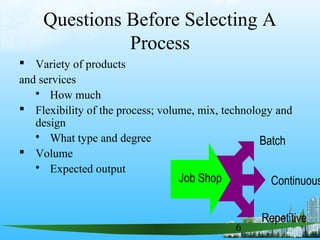

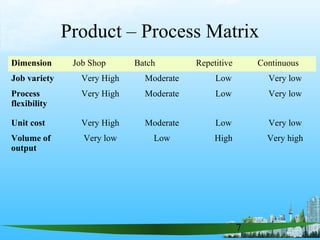

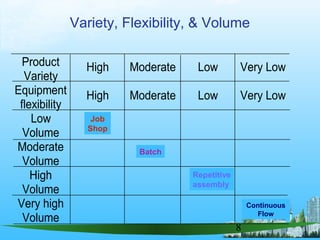

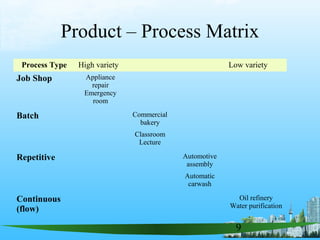

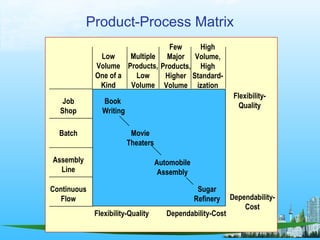

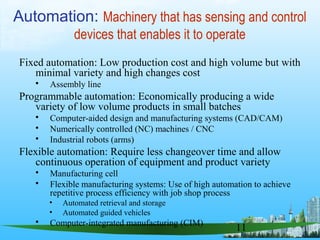

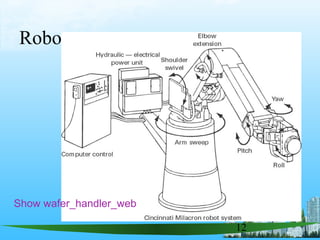

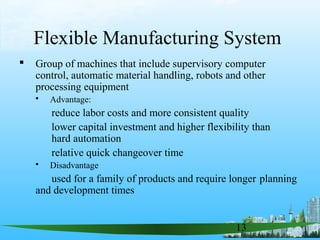

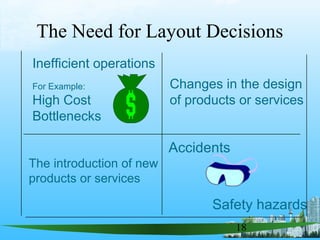

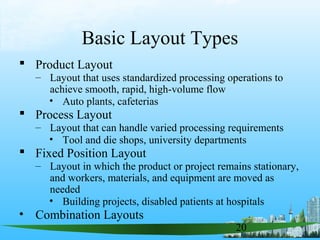

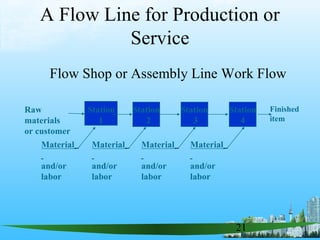

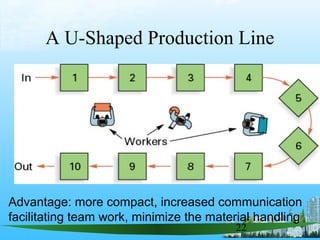

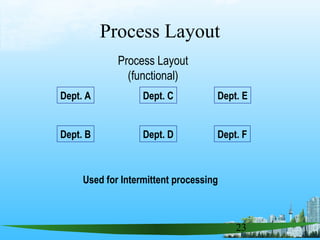

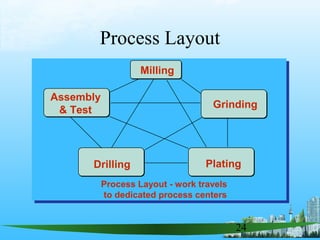

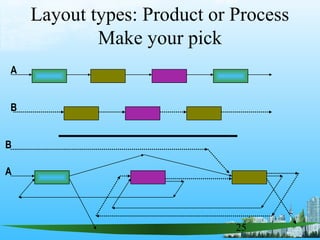

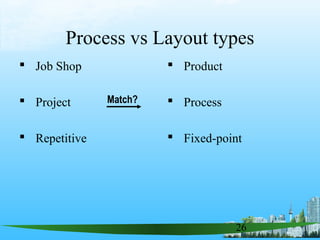

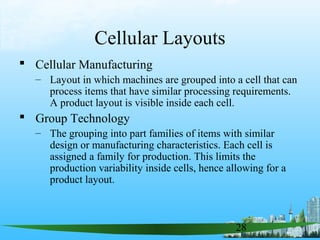

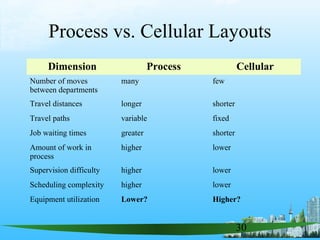

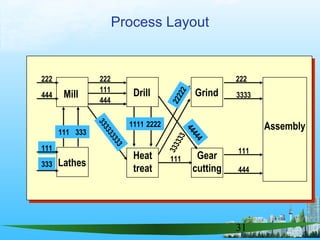

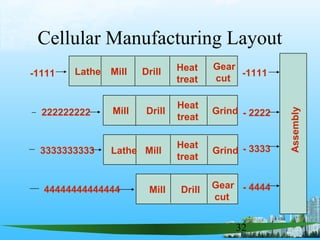

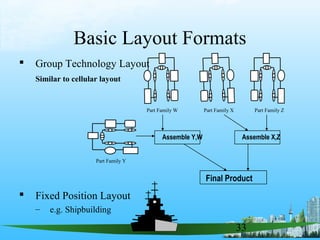

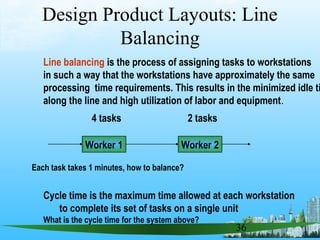

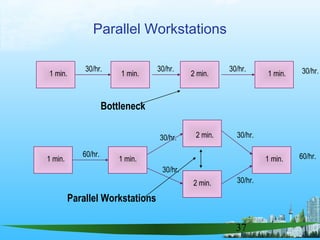

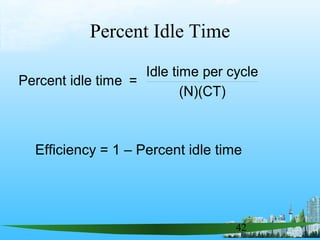

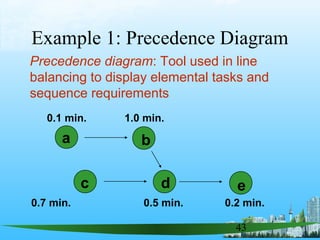

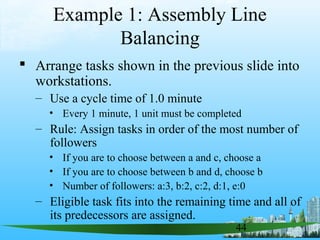

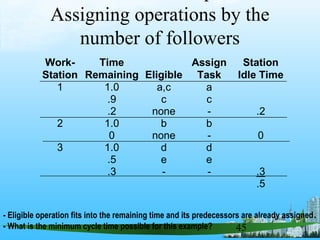

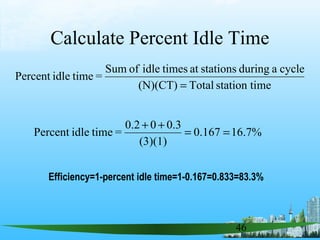

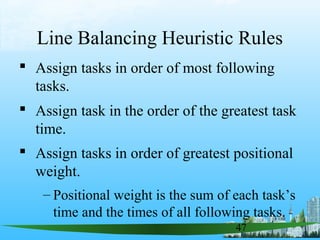

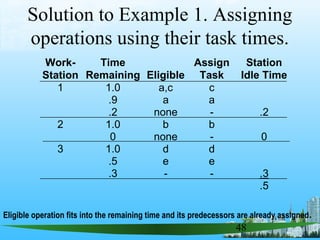

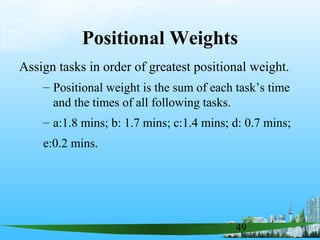

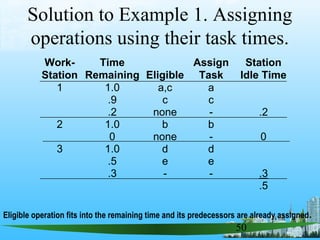

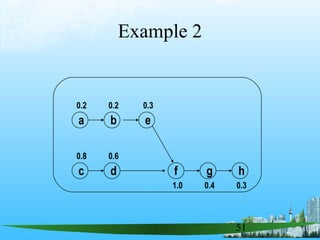

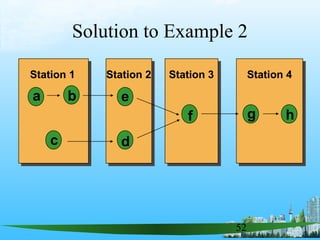

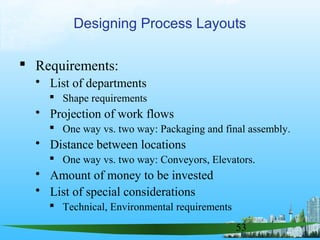

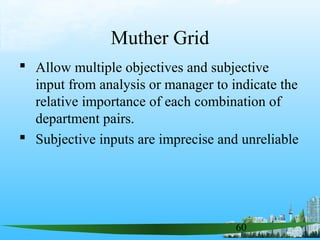

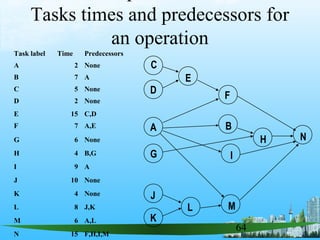

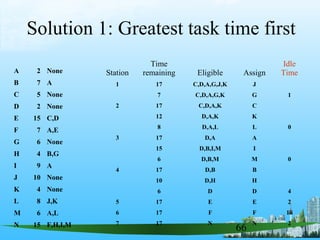

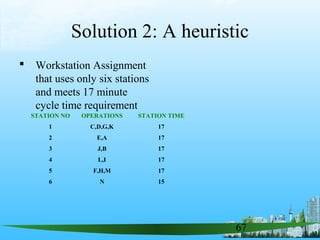

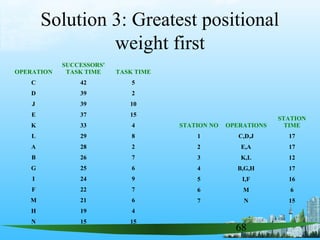

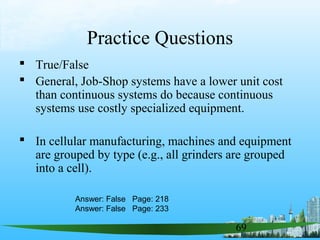

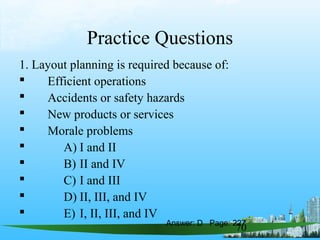

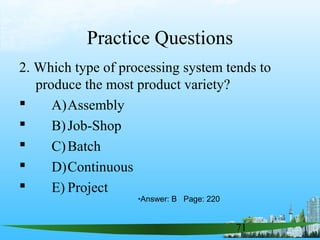

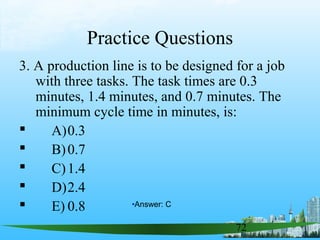

This document discusses process selection and facility layout. It begins by introducing key considerations in process selection such as product variety, volume, and flexibility. The main types of processes are then described including job shops, batch processing, repetitive/assembly, and continuous processing. A product-process matrix is presented to help match the appropriate process type to different product characteristics. The document then covers automation approaches and different layout types including product, process, group technology, and cellular layouts. It analyzes the advantages and disadvantages of different layouts and process types. Line balancing techniques for designing efficient production layouts are also introduced.