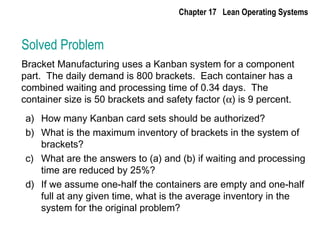

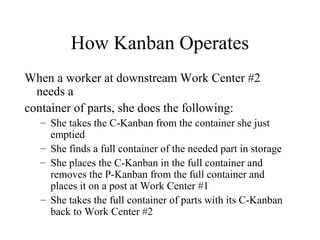

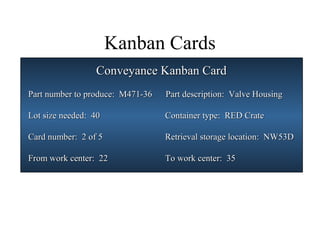

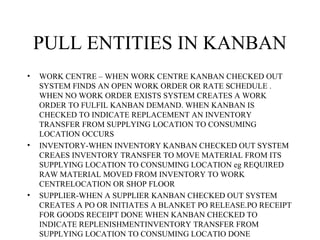

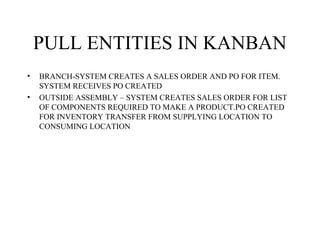

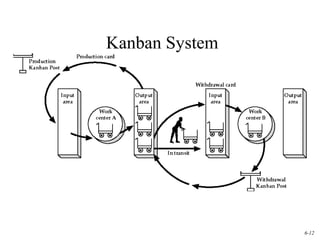

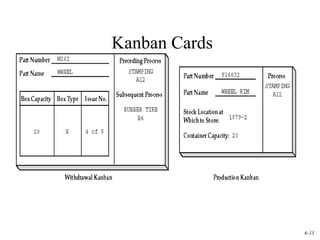

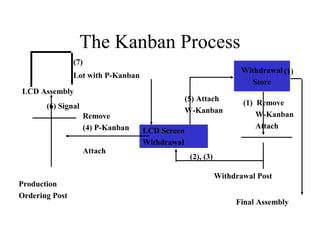

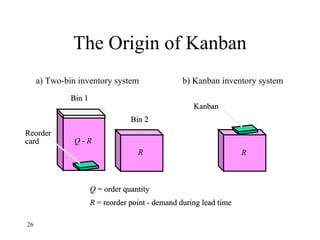

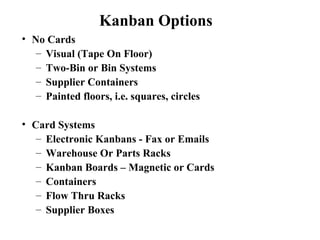

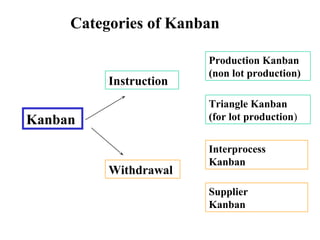

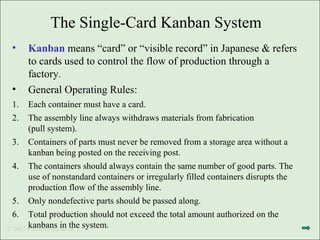

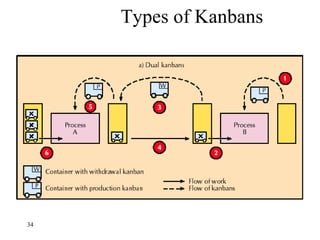

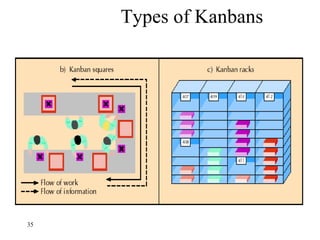

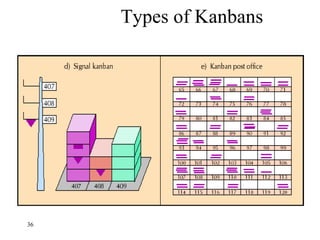

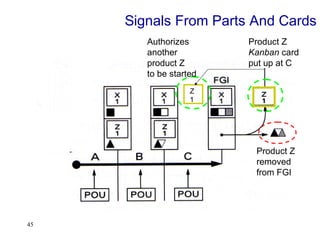

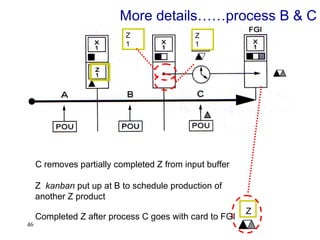

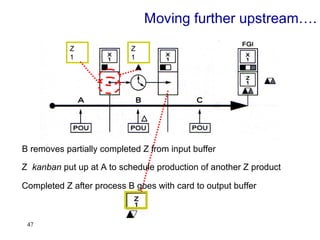

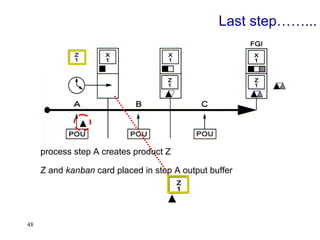

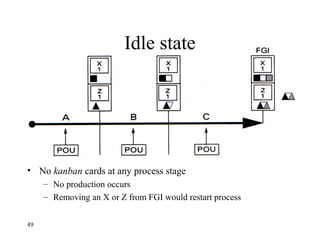

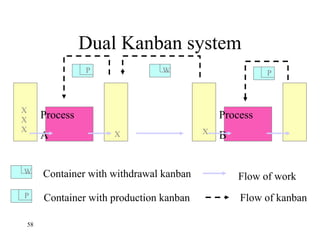

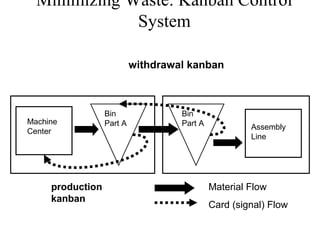

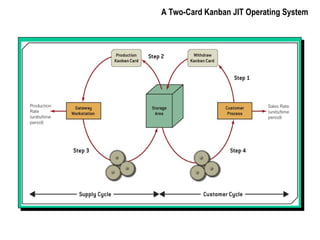

Kanban is a pull system that uses visual signals to control work in process inventory and optimize material flow. It originated at Toyota in the 1950s to manage production line material flows using cards to signal the need for parts replenishment. Kanban limits work in process inventory by only authorizing production of additional inventory as and when needed, as signaled by empty containers. The key aspects of Kanban include using cards or signals to communicate production orders between processes, standardizing container sizes, and limiting inventory to just what is needed by the downstream process.

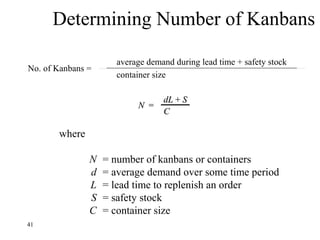

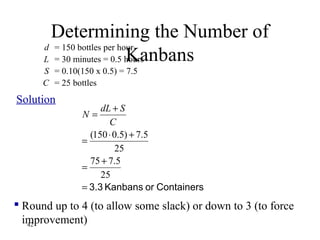

![Number of Kanban Cards Required:

K = d(p + w)(1+ α) [17.1]

C

where K = the number of Kanban cards in the operating system.

d = the average daily production rate as determined from the

master production schedule.

w = the waiting time of Kanban cards in decimal fractions of a

day (that is, the waiting time of a part).

p = the processing time per part, in decimal fractions of a day.

C = the capacity of a standard container in the proper units of

measure (parts, items, etc.).

α = a policy variable determined by the efficiency of the

process and its workstations and the uncertainty of the

workplace, and therefore, a form of safety stock usually

ranging from 0 to 1. However, technically there is no

upper limit on the value of α.

Chapter 17 Lean Operating Systems](https://image.slidesharecdn.com/kanban1-140329054118-phpapp02/85/Kanban-1-62-320.jpg)