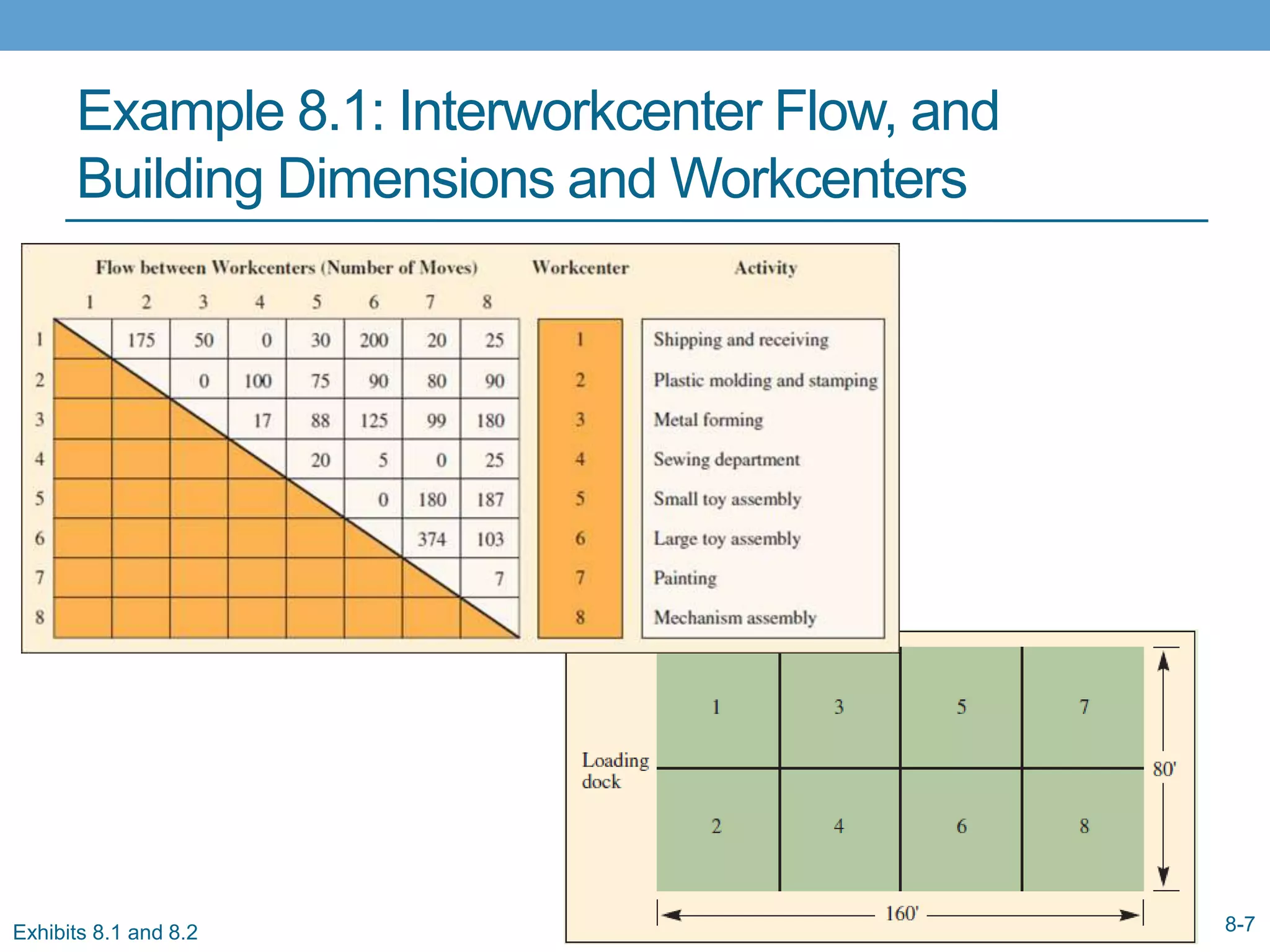

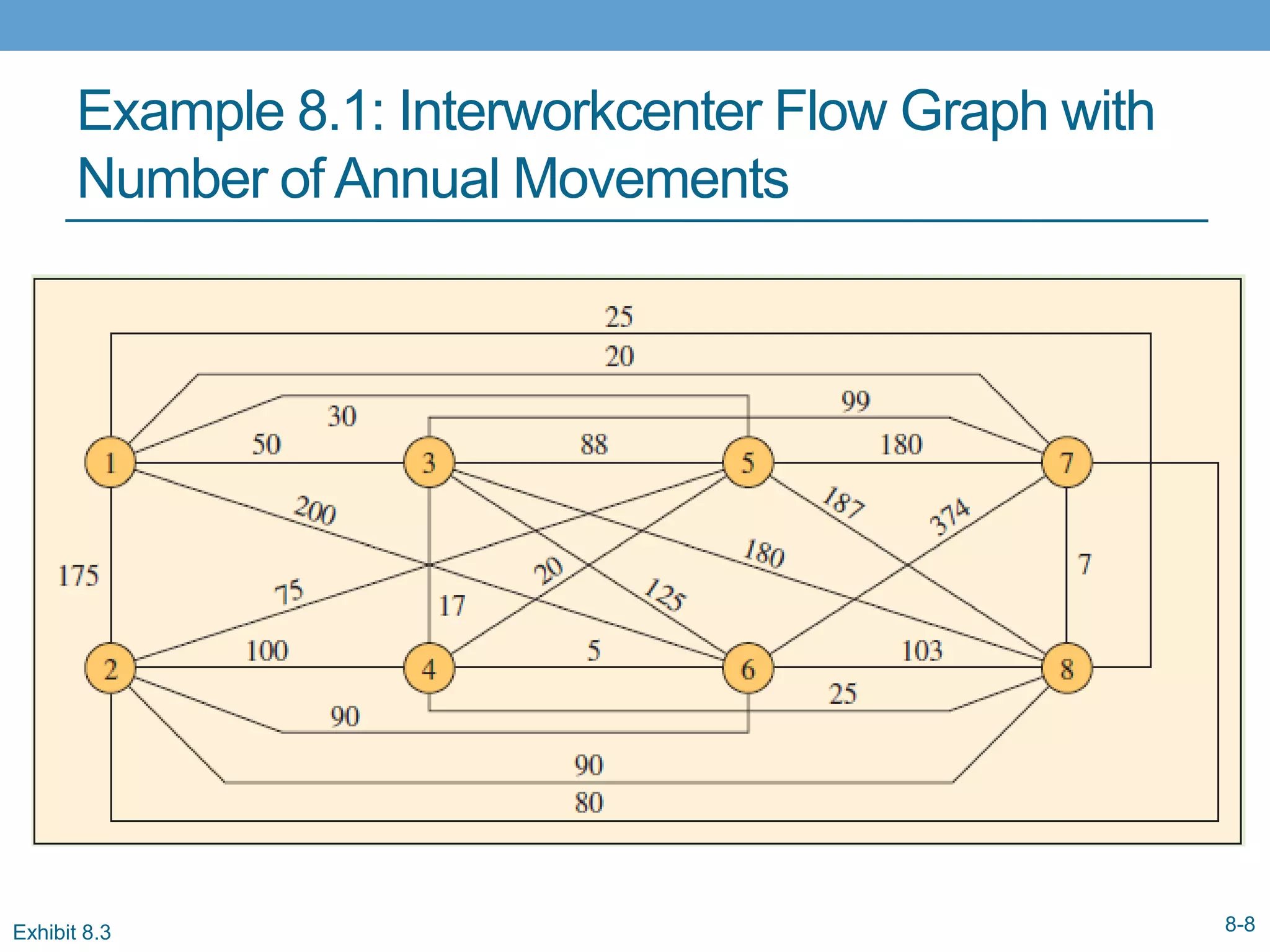

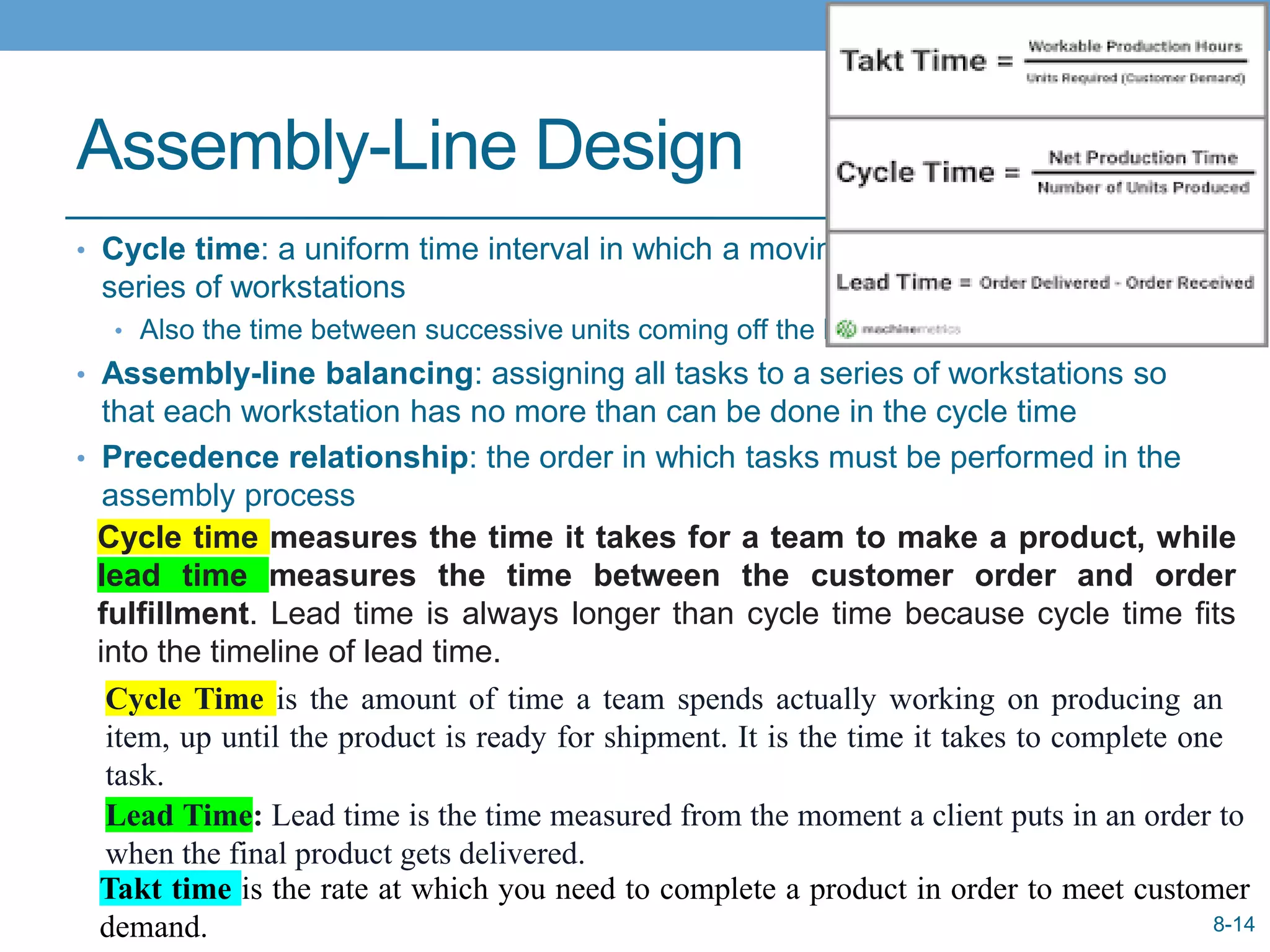

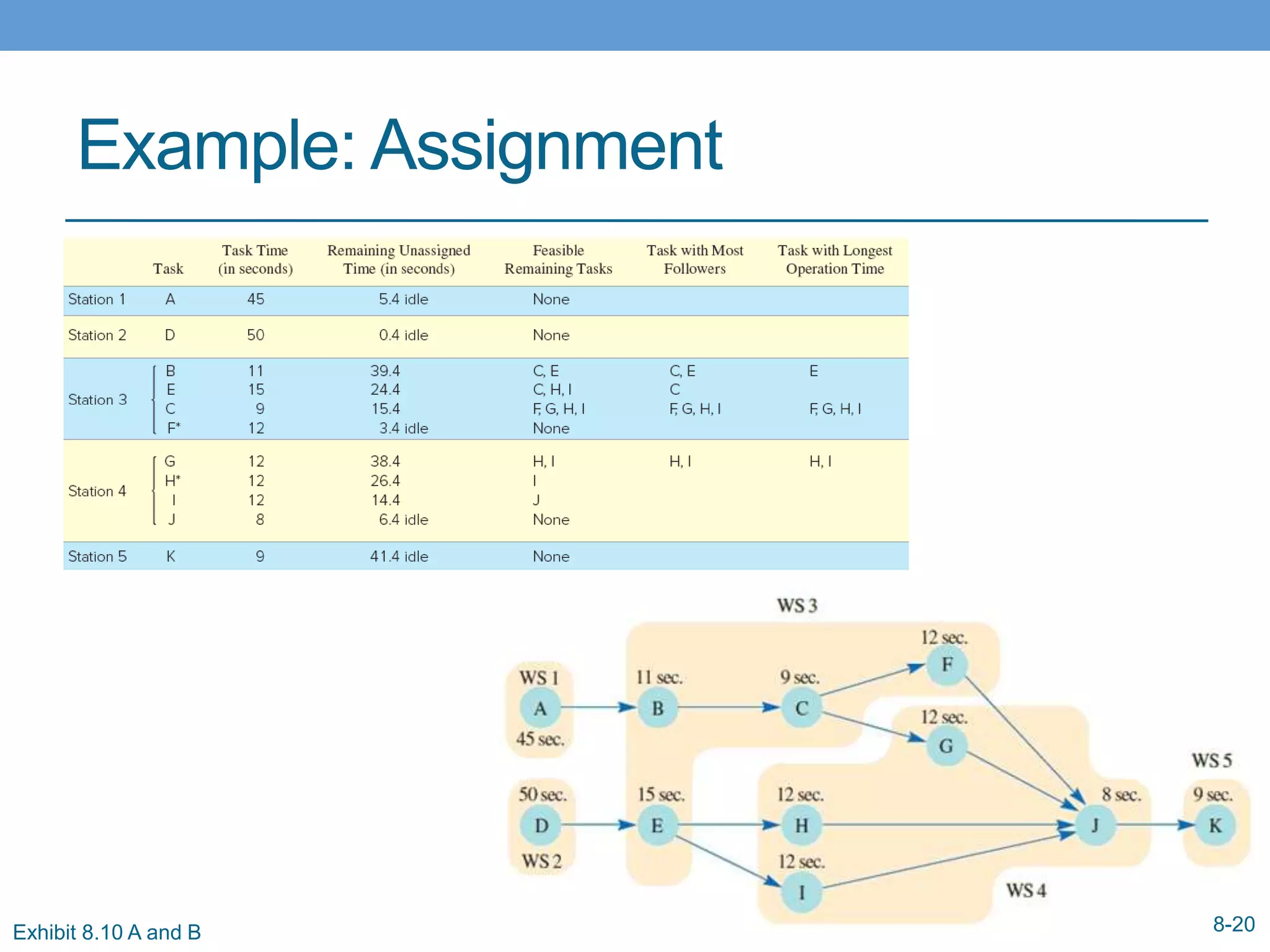

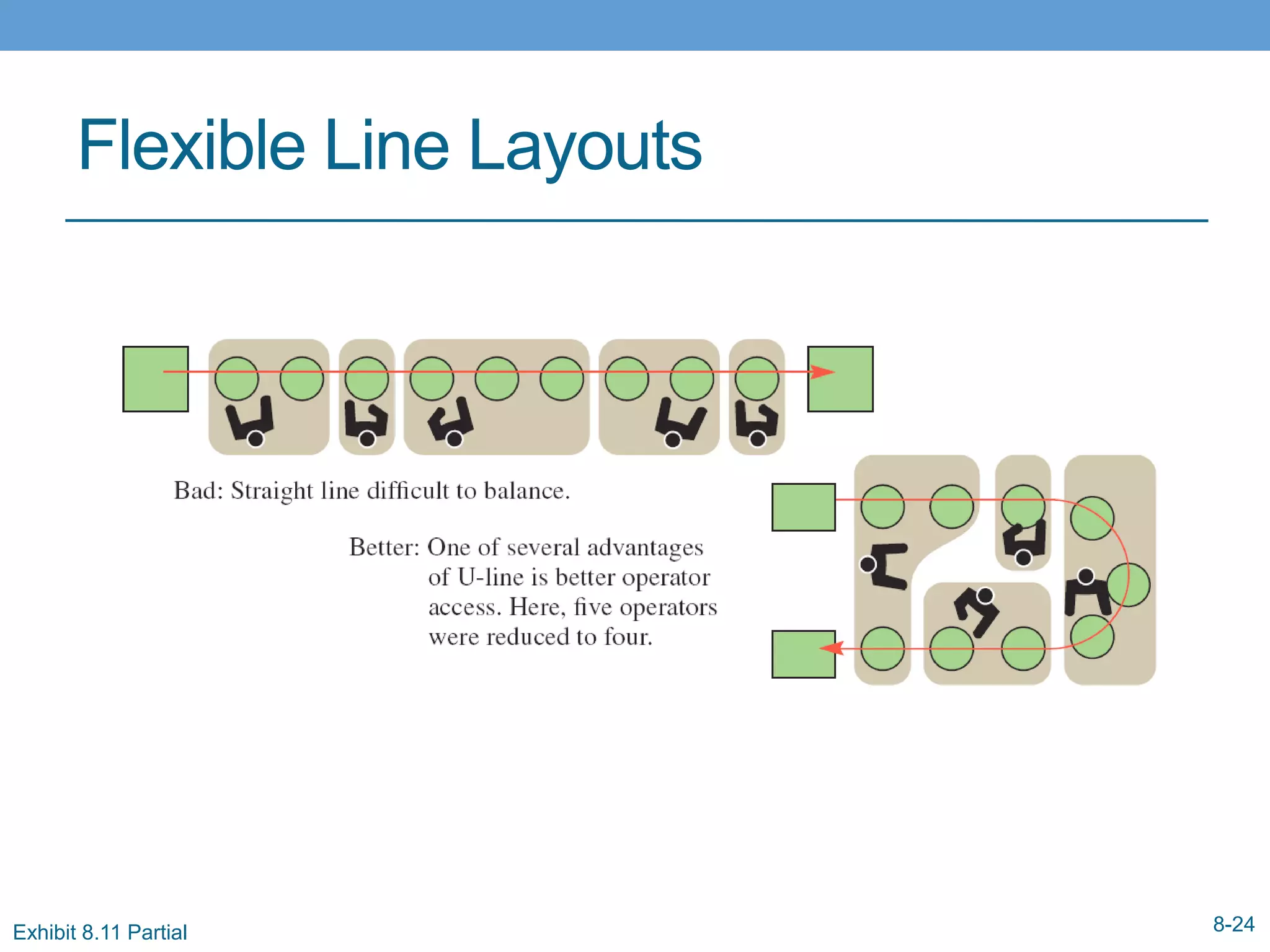

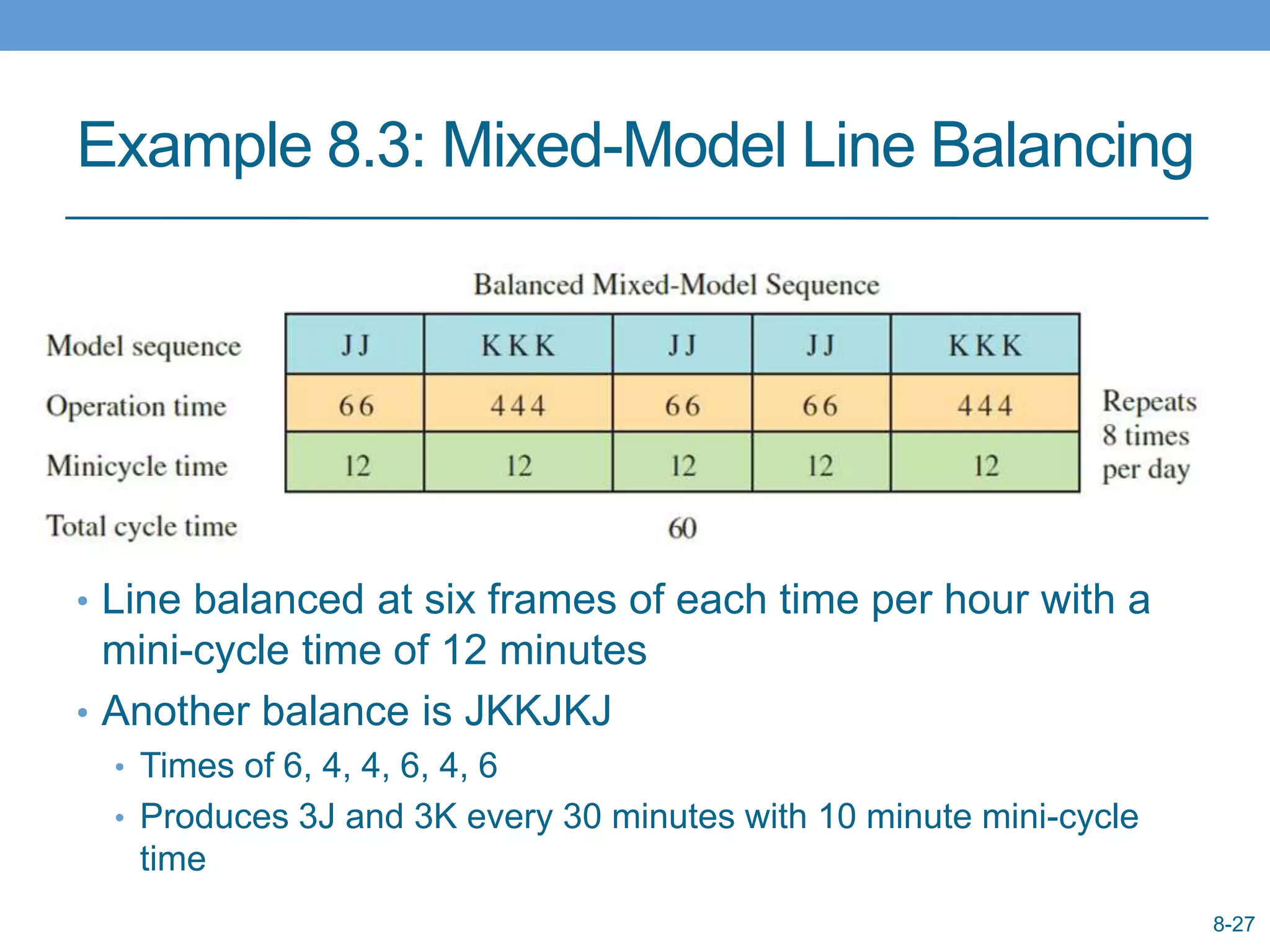

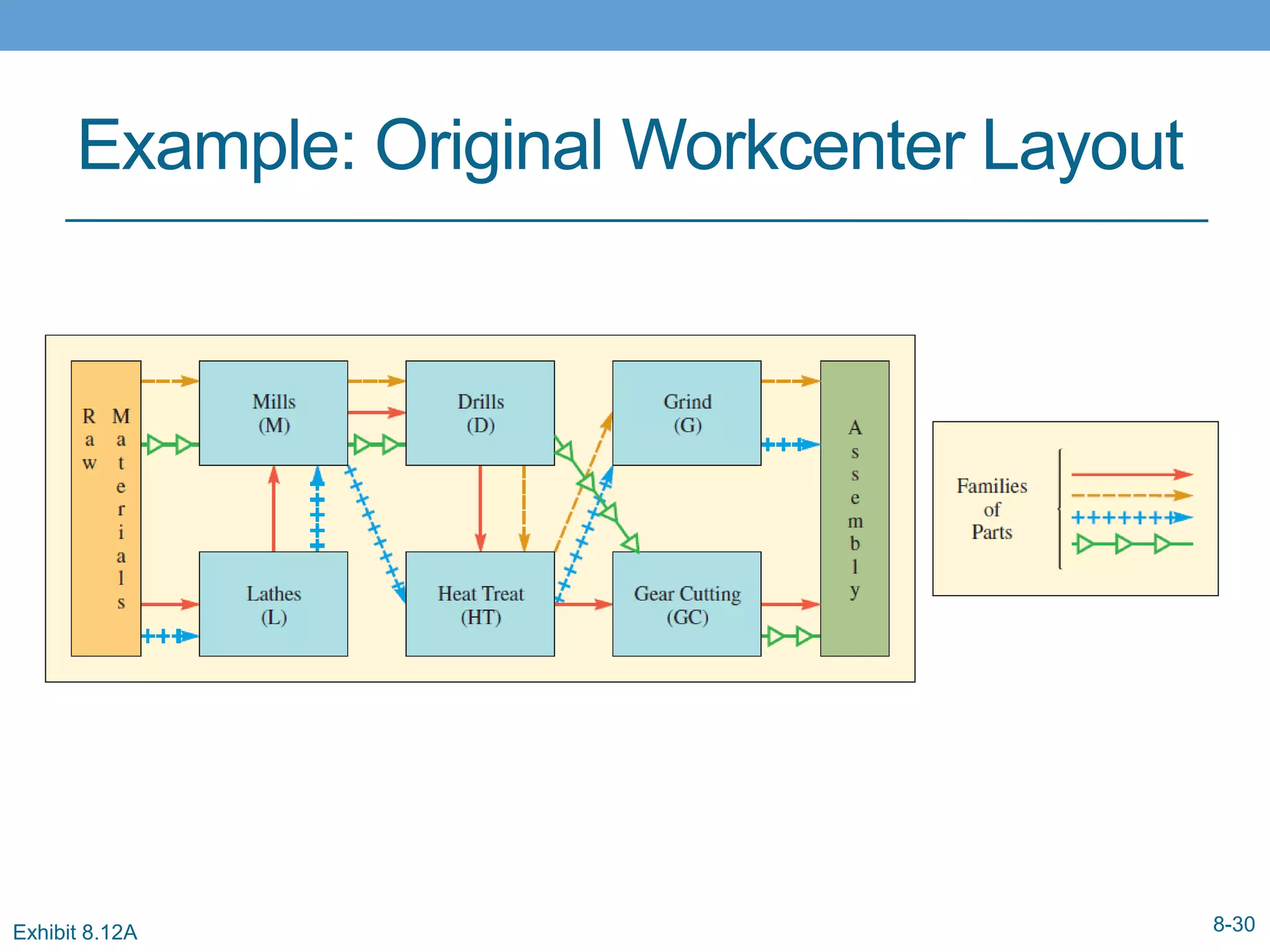

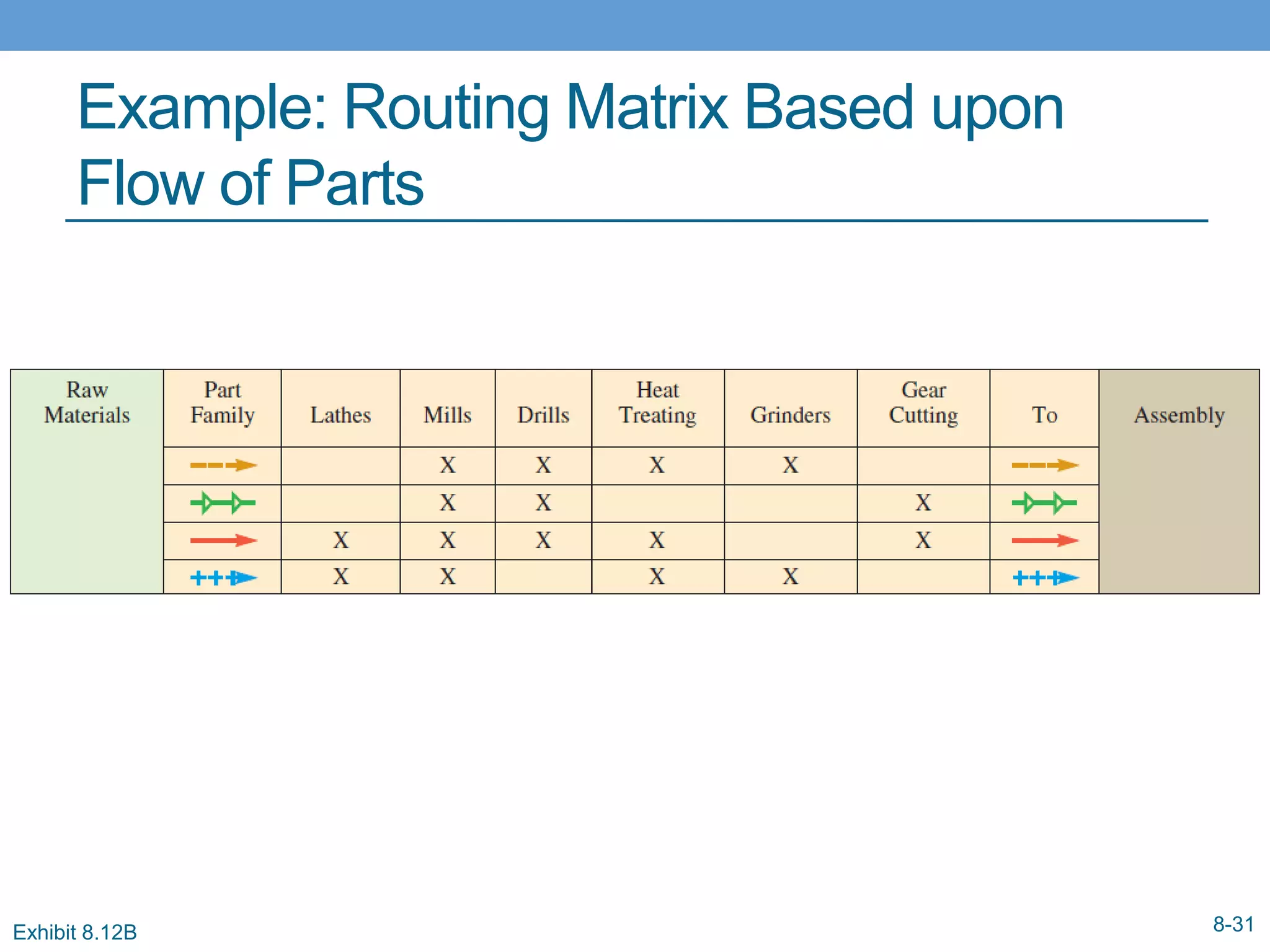

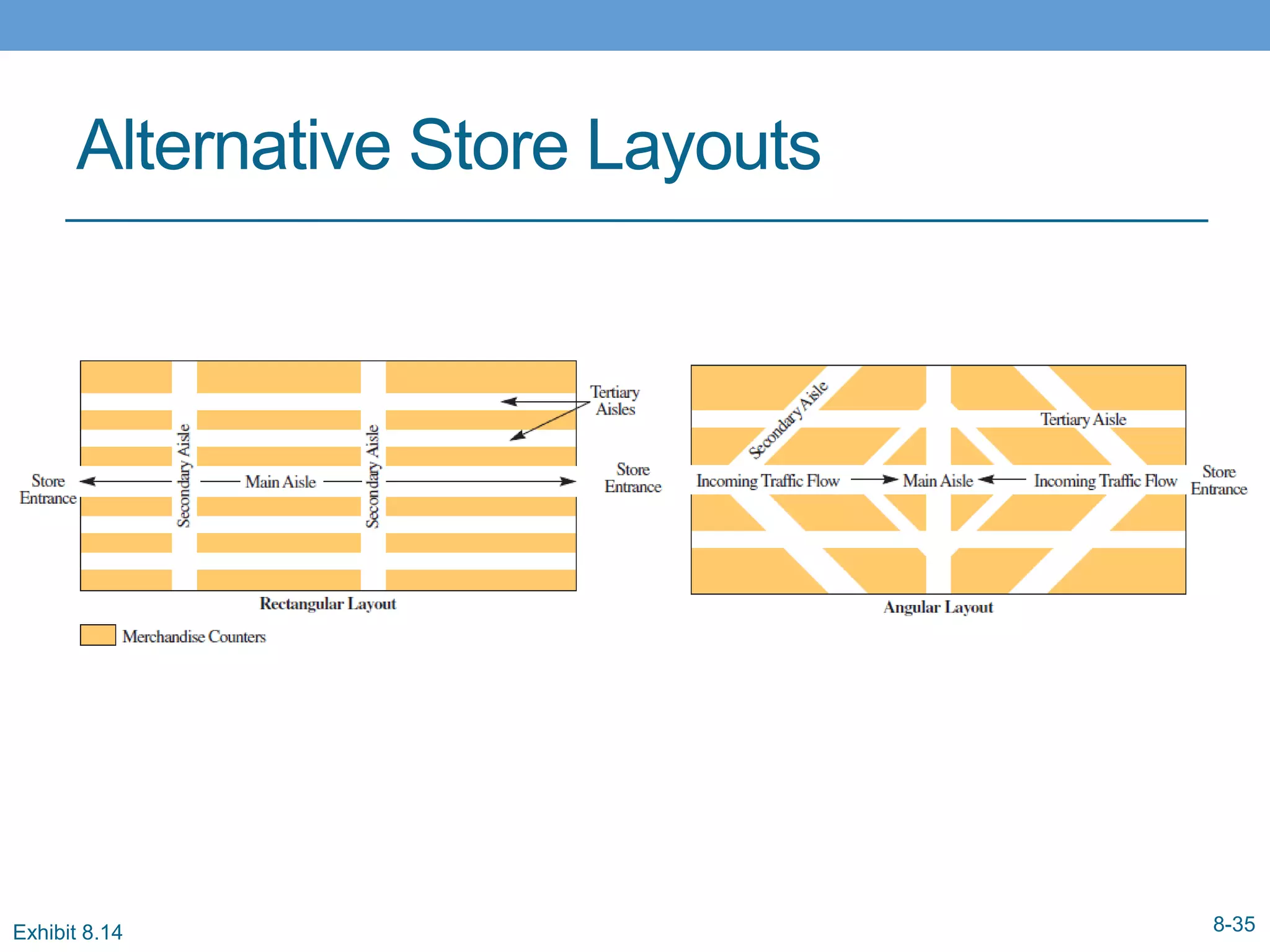

This document provides an overview of facility layout concepts. It discusses common manufacturing layouts like workcenter layouts, assembly lines, and manufacturing cells. It also covers techniques for analyzing and designing layouts, such as workcenter layout analysis, systematic layout planning, assembly line balancing, and mixed-model line balancing. Additionally, it briefly discusses non-manufacturing layouts for offices and retail stores. The focus is on quantitative techniques for optimizing layout design to improve material flow and productivity.