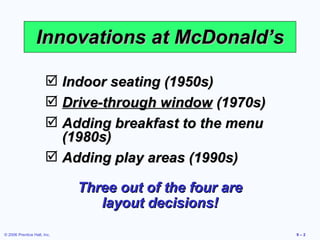

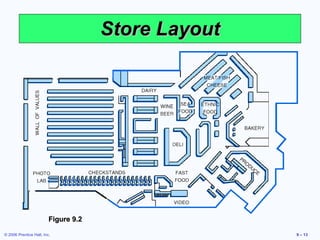

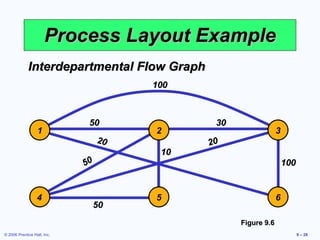

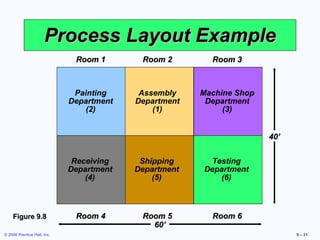

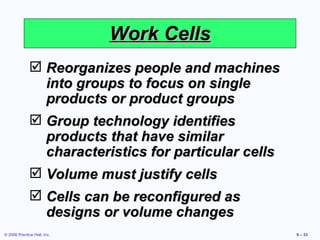

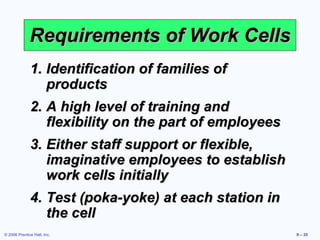

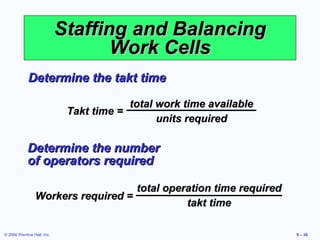

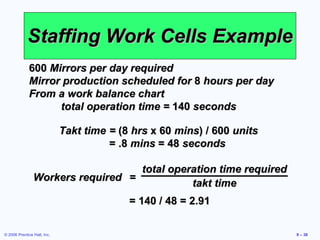

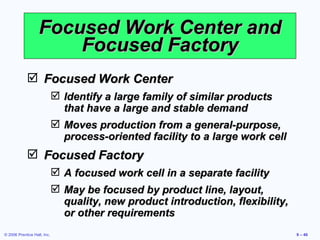

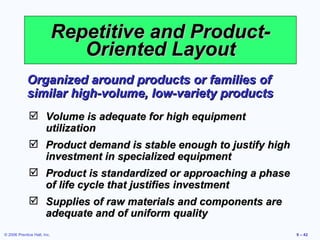

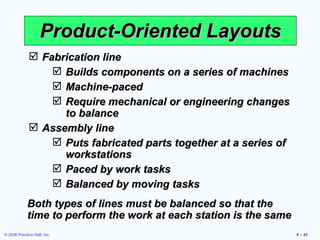

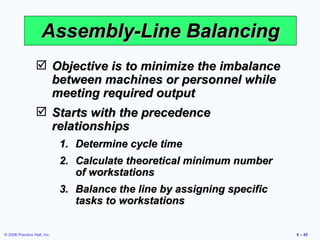

The document discusses different types of layout strategies used in operations management. It describes layouts for offices, retail stores, warehouses, and manufacturing facilities. For manufacturing facilities, it outlines process-oriented layouts where similar machines are grouped, work cell layouts that focus on single products, and product-oriented layouts that optimize personnel and machine utilization for repetitive production. Good layouts consider factors like material handling, space usage, and employee and customer flows.