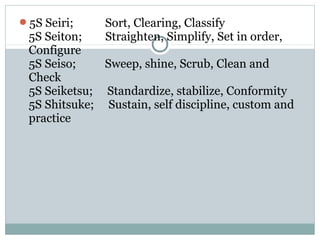

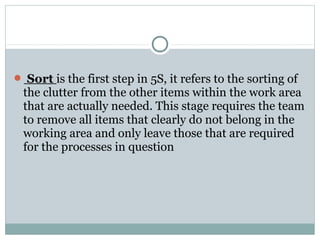

Lean manufacturing aims to eliminate waste and optimize efficiency. It was developed by Toyota and popularized by James Womack. The goal is to satisfy customers with quality products delivered quickly at low cost. Key aspects include just-in-time production, continuous improvement, and 5S techniques. Agile manufacturing focuses on flexibility and responsiveness to meet changing customer needs through modular design, information technology, partnerships, and a knowledge culture. Both approaches emphasize eliminating waste while delivering value to customers.