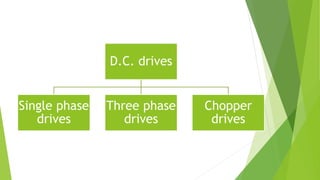

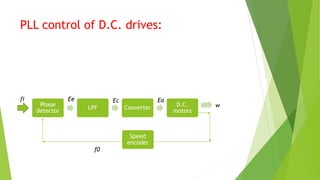

This document summarizes control of DC drives. It discusses types of DC motor configurations including series and separately excited motors. It describes single phase and three phase DC drives that use converters depending on the supply available. Chopper drives are discussed as a way to control DC motor speed by adjusting the duty cycle and switching frequency of the chopper output voltage. Phase locked loop control of DC drives is also mentioned as a way to precisely control motor speed by synchronizing the motor speed pulses to a reference frequency pulse train. Applications of DC drives include rolling mills, paper mills, printing presses, mine winders and machine tools.