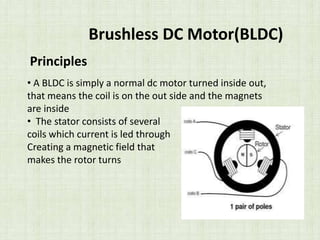

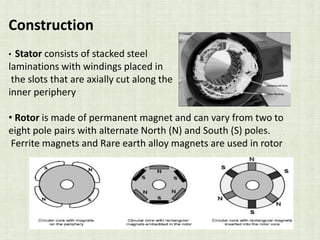

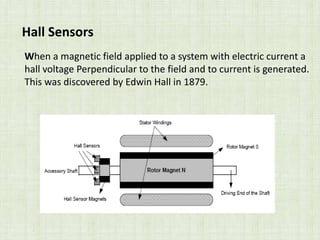

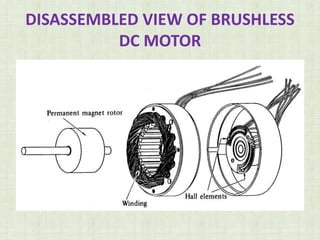

Brushless DC motors have magnets inside the rotor and coils outside in the stator. They use electronic commutation rather than brushes to switch the current through the coils to rotate the motor. They have advantages over brushed DC motors like increased reliability, efficiency, and lifespan due to eliminating sparks from the commutator. However, they require more complex drive circuitry and position sensors. Applications include consumer goods like fans, tools, and toys as well as medical devices like artificial hearts and surgical tools.