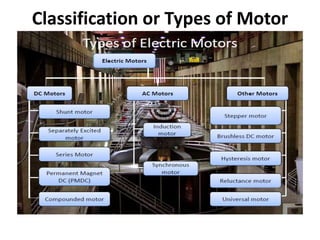

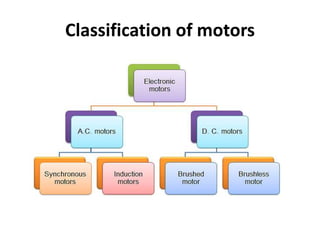

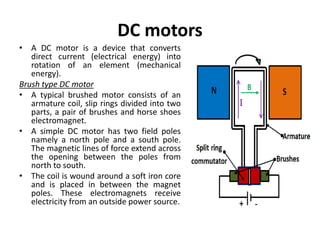

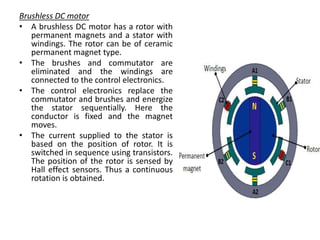

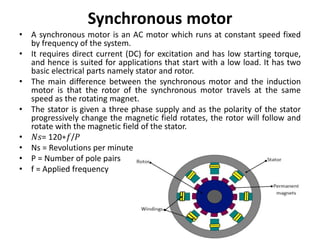

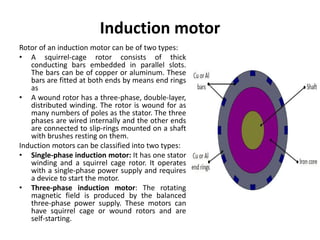

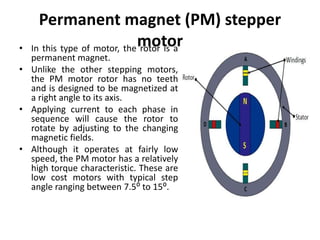

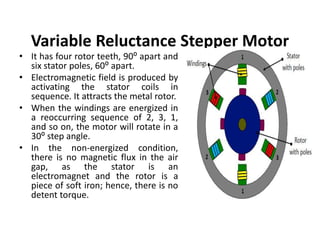

The document discusses different types of electrical motors. It describes DC motors, including brushed and brushless types. It also covers AC motors like synchronous and induction motors. Stepper motors are also summarized, including permanent magnet and variable reluctance types. The key properties and applications of each motor type are highlighted at a high level.