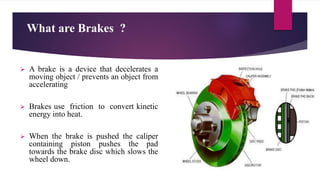

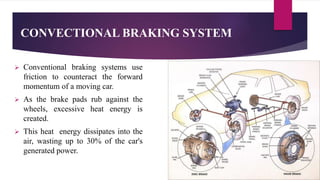

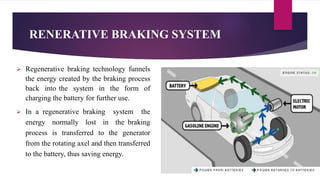

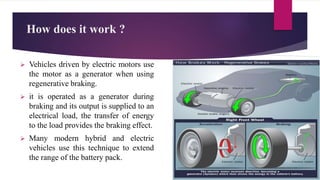

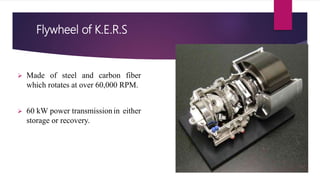

This document discusses regenerative braking systems. It begins by explaining conventional braking systems, noting that they waste up to 30% of a car's energy through heat dissipation. Regenerative braking systems instead funnel the energy from braking back into the battery. During braking, the electric motor acts as a generator to transfer kinetic energy into electrical energy stored in the battery. This extends the vehicle's range. The key components are the brake drum, friction lining, controller, electric generator, and linking mechanism. Regenerative braking provides benefits like reduced pollution, increased engine life, and wear reduction by recapturing lost kinetic energy.